Gear technology and automation systems

Gear technology and automation systems

Machine concept

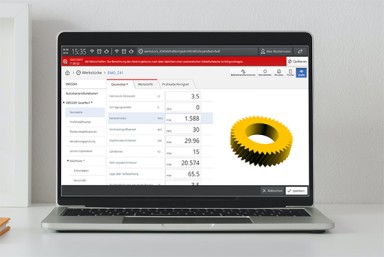

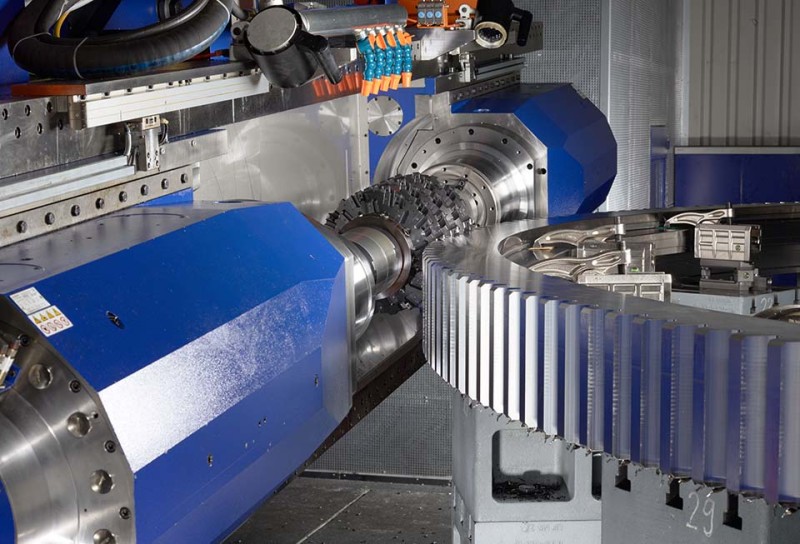

Is performance-related gear cutting possible on your machine? As nowadays the need to be economical is more important than ever, modern machines are required.

The Liebherr LC series ensures reliable machining with the required torques and cutting forces. This allows us to reinforce the capability of modern CNC gear hobbing machines.

The machine concept fulfills quality requirements such as accuracy, stability and temperature resistance. Stable processes are realized during pre- and finish cutting.

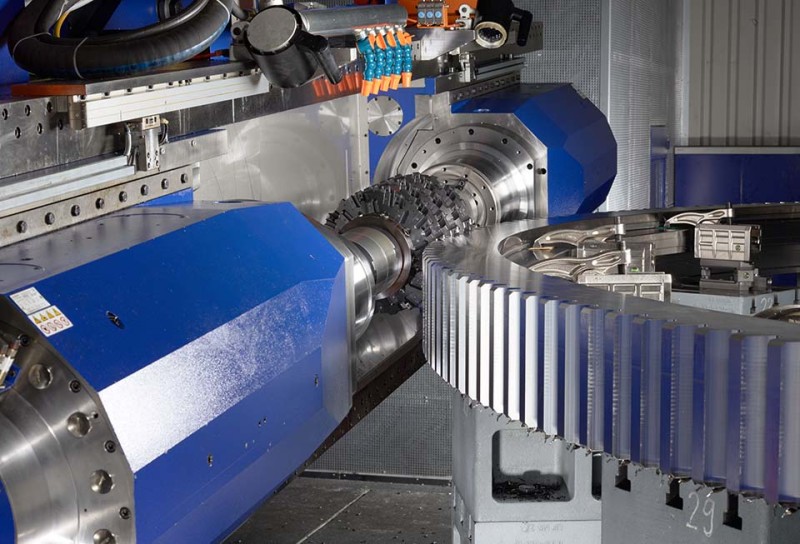

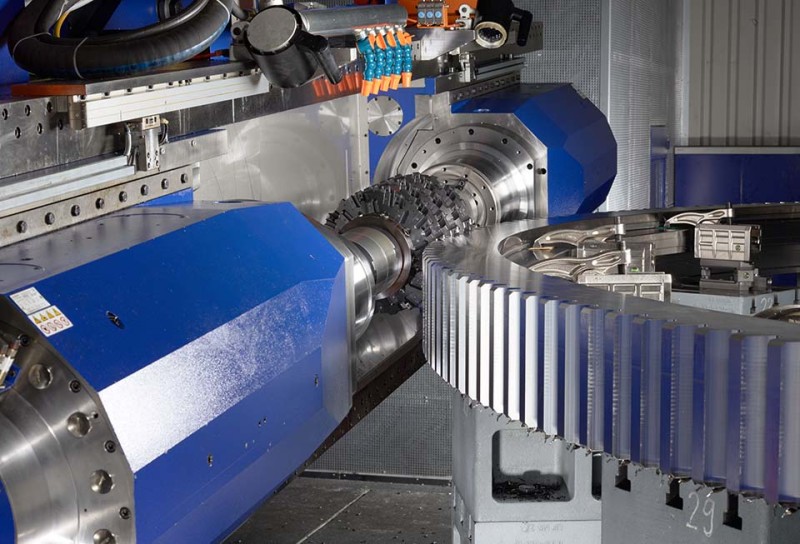

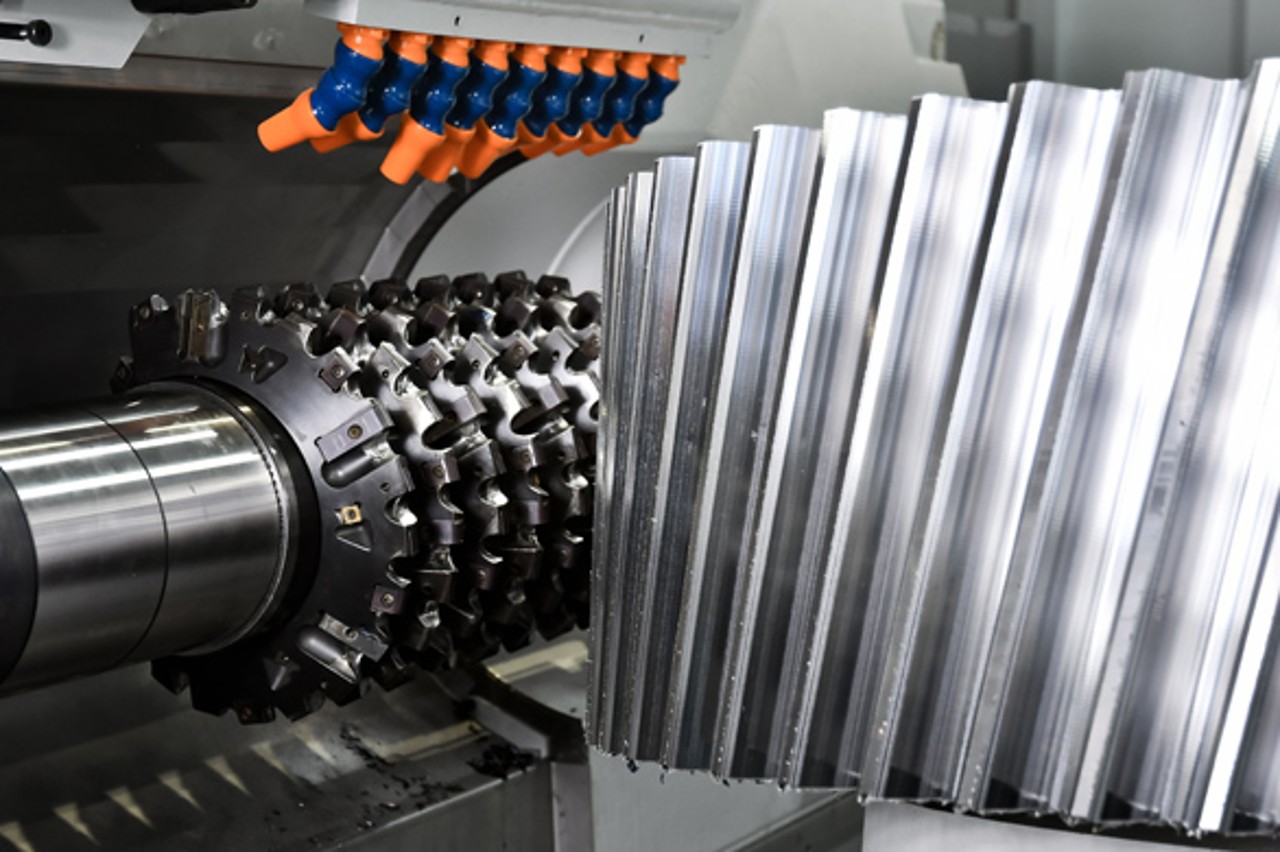

Is dry gear hobbing for large modules (m>10) possible? Yes, as you can see in the picture on the left.

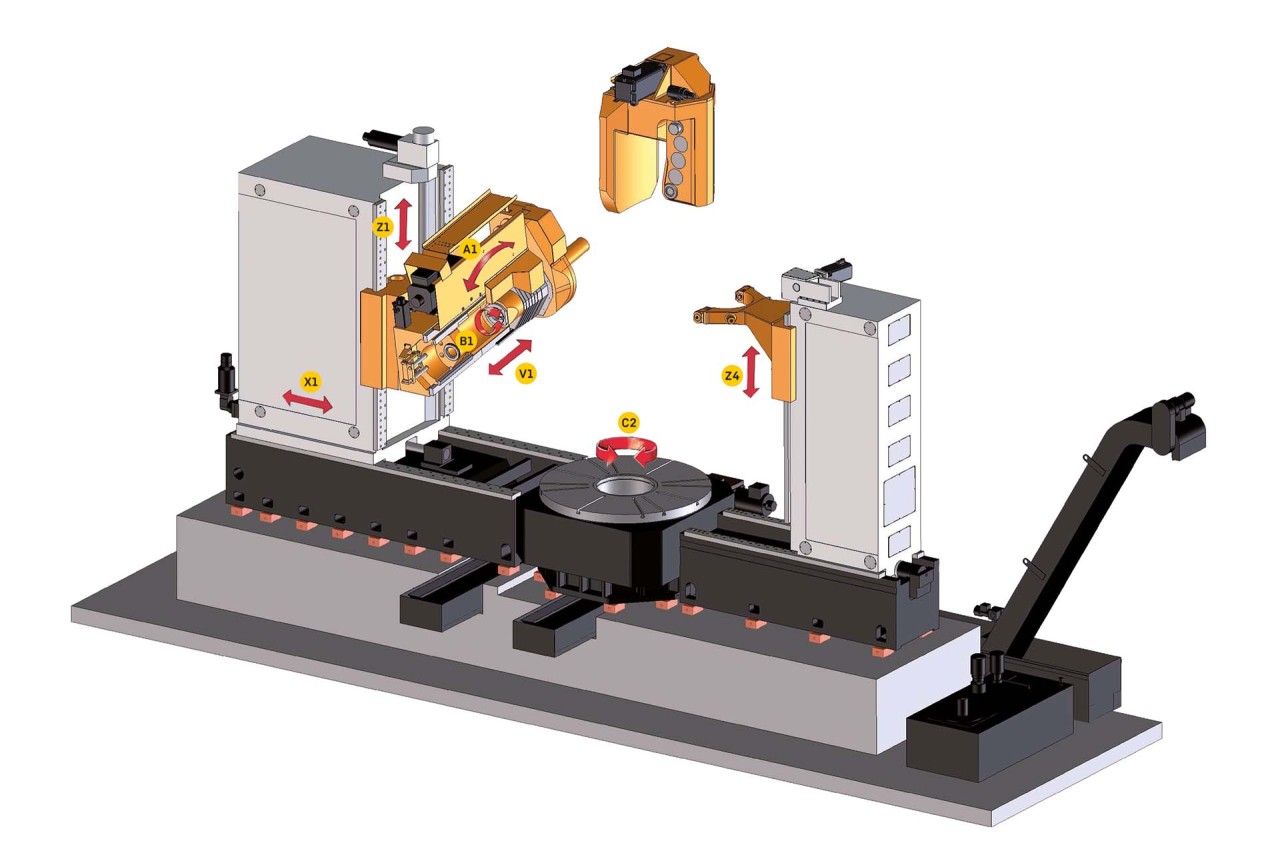

- Flexible layouts possible

- Chip conveyor can be retracted if required (shaft machining)

- Temperature stable, as there is no direct connection between machine table, machine bed and counter column. The connection is made via the foundation.

- Welded machine bed for higher rigidity

- Hardened guideways

- Use of flat guides for increased damping and reduction of vibrations

X1 - Radial movement column slide | V1 - Tangential movement tool | Z1 - Axial travel tool | B1 - Rotary movement tool | C2 - Rotary movement workpiece | A1 - Swivel movement tool | Z4 - Vertical travel tailstock

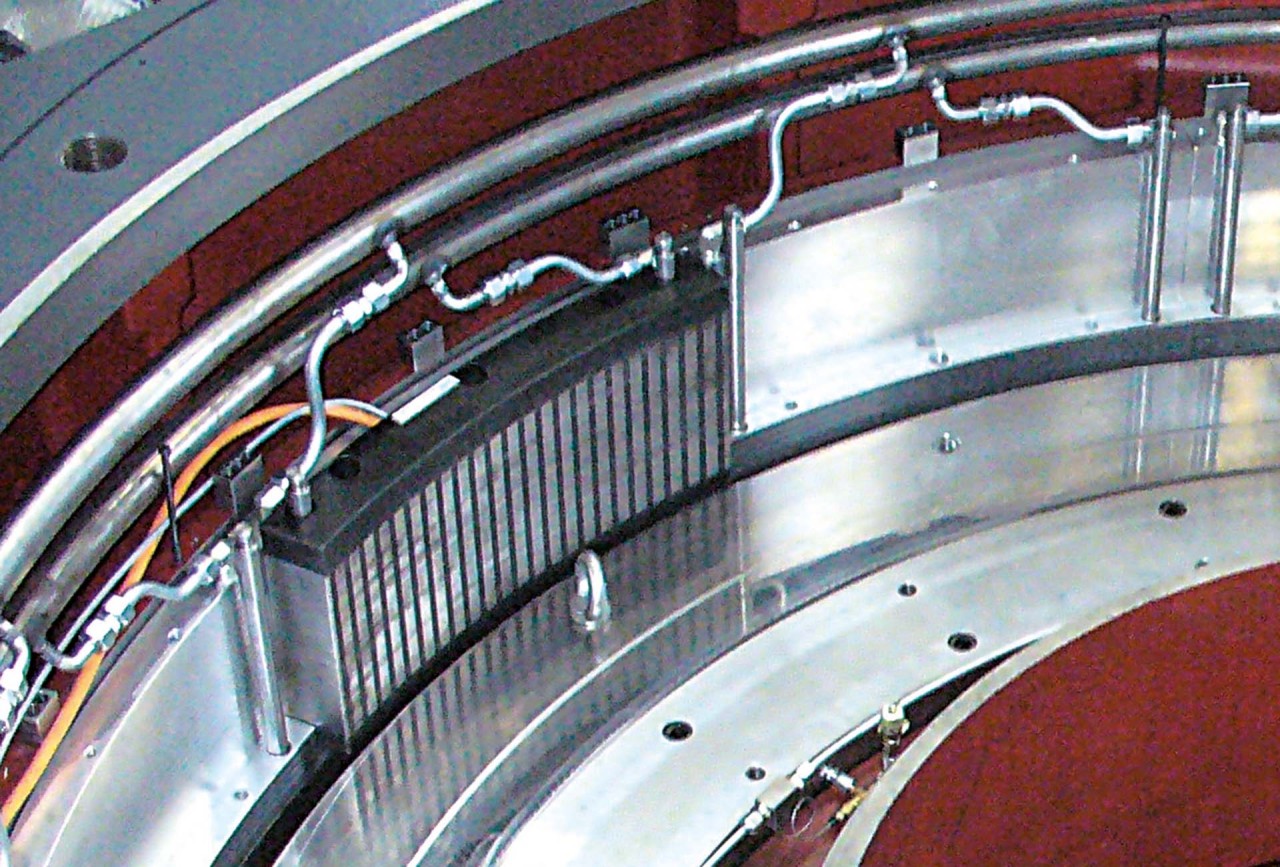

Process-related drive selection

In this series, you can select between direct drive and gear drive.

All machine tables are equipped with a hydrostatic bearing.

Picture on the left: Machine table with direct drive

Process-related drive selection

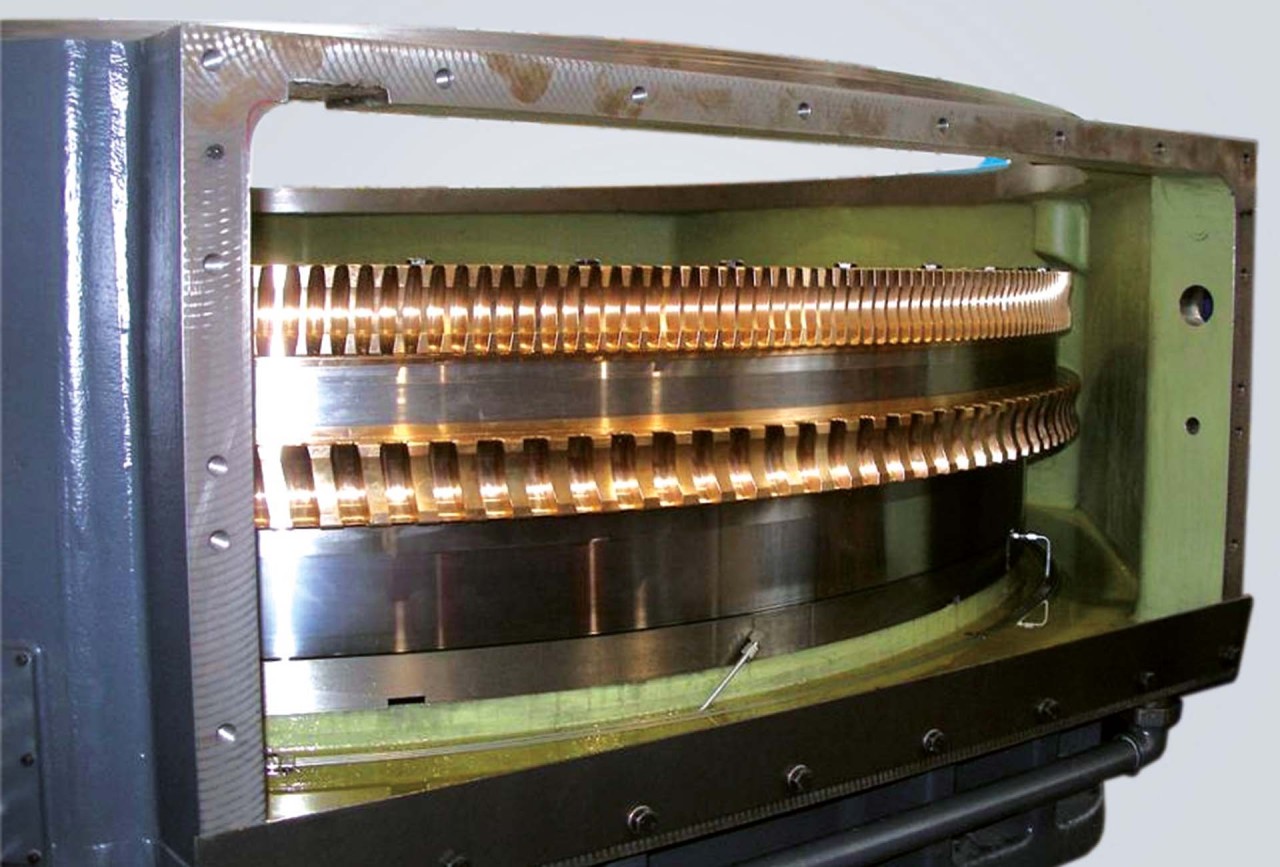

For internal machining of workpieces, chip removal can be done through the table bore.

Figure on the left: Machine table with double worm drive

Hob heads

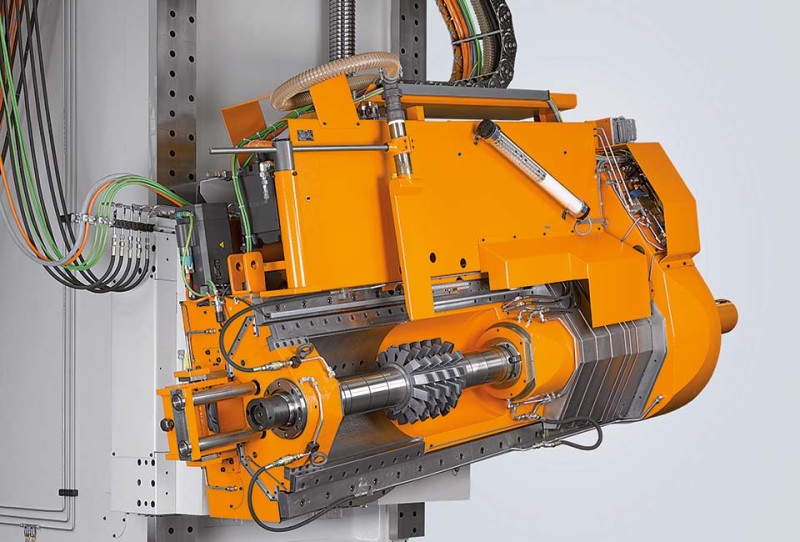

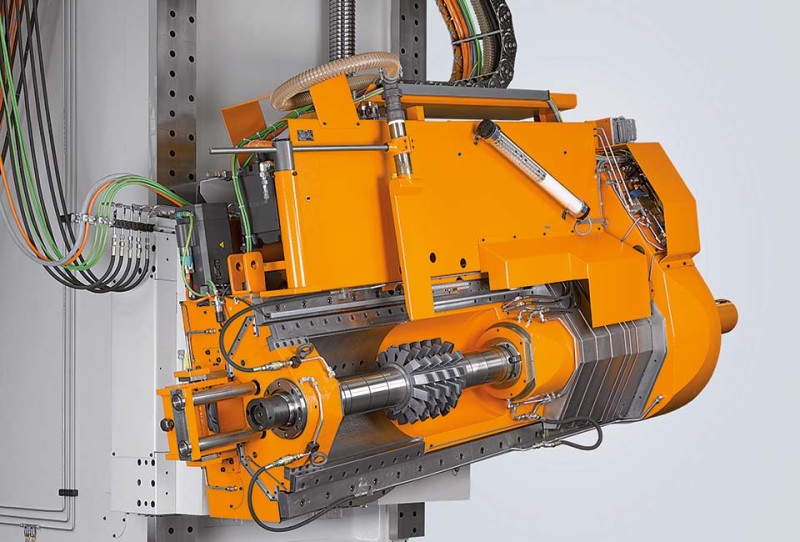

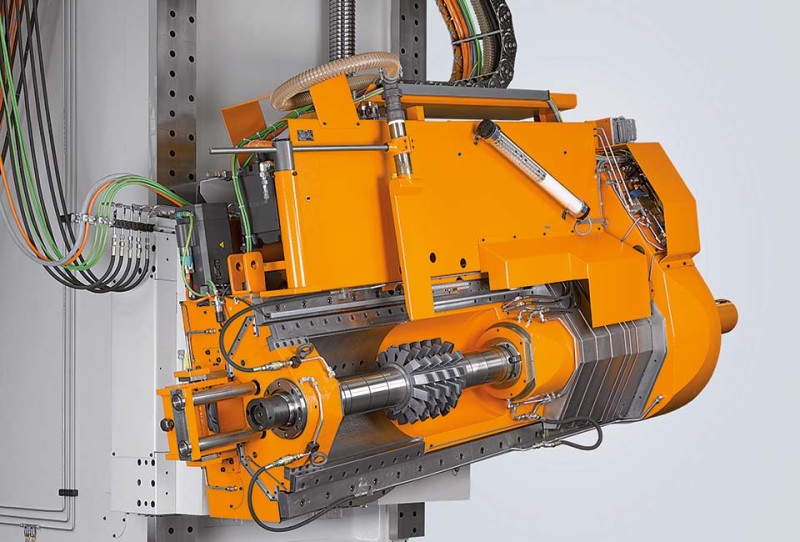

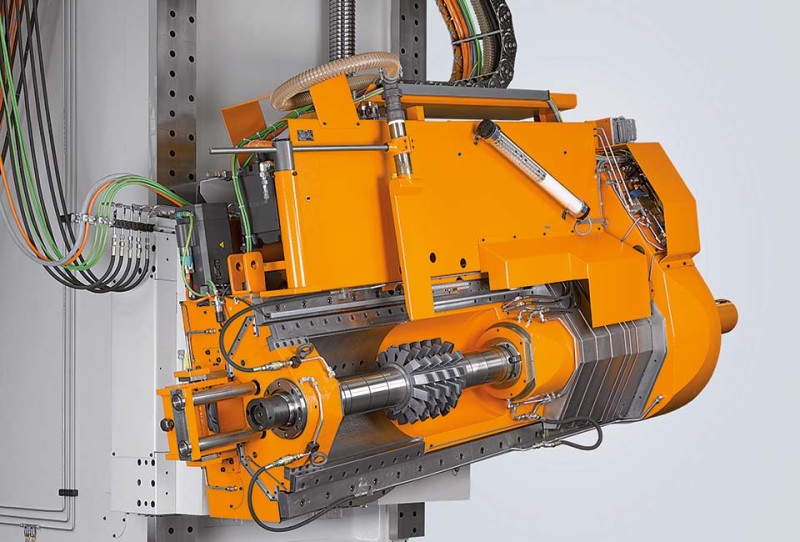

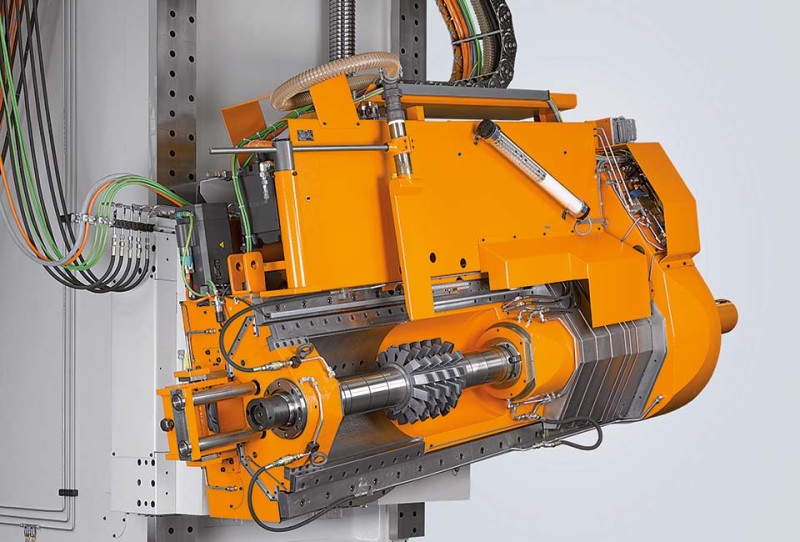

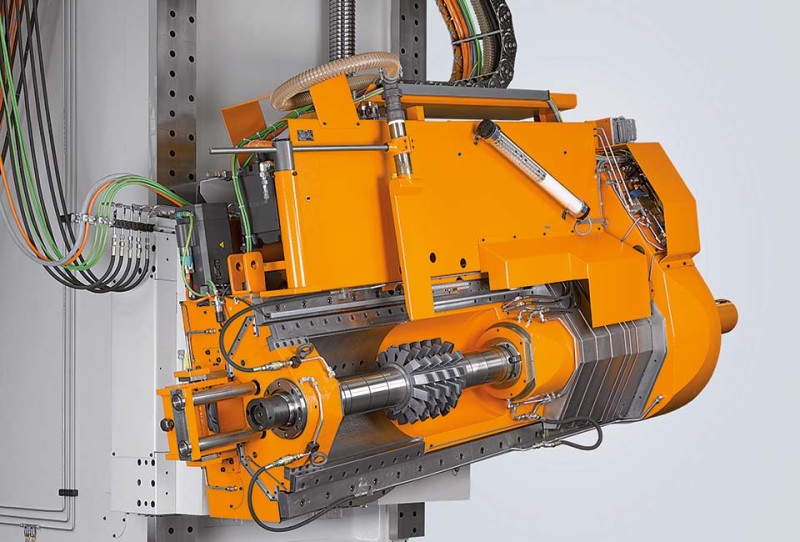

Gear hobbing head HH 450 DD

- Drive power: 53 KW

- Module 24/30

- max. hob speed 250 rpm

- max. hob diameter 320 mm

- max. hob length 440 mm

- max. tangential distance 300mm

- max. tangential speed 500 mm/min

Gear hobbing head HH 450 DD

- Less torsion in the hob arbor thanks to torque introduction from both sides

- Optimum interfering contour

- Available with oil, emulsion and air cooling

- Adjustable coolant nozzle via control panel

- Drive power: 102 KW

- Module 30

- max. hob speed 275 rpm

- max. hob diameter 450 mm

- max. hob length 600 mm

- max. tangential distance 450 mm

Gear hobbing head FK4.2

- Drive power: 70 KW

- Module 30/40

- max. hob speed 250 rpm

- max. hob diameter 450 mm

- max. hob length 700 mm

- max. tangential distance 450 mm

- max. tangential speed 500 mm/min

Gear hobbing head HH 500 DD

- Optimum interfering contour (suitable for workpieces up to 16 meters in diameter)

- Available with oil, emulsion and air cooling

- Adjustable coolant nozzle via control panel

- Drive power: 110 KW

- Module 50/60

- max. hob speed 250 rpm

- max. hob diameter 520 mm

- max. hob length 800 mm

- max. tangential distance 600 mm

- Index milling head IFK4.11

- Quick cutter head change thanks to simplified interface

- Available with oil, emulsion and air cooling

- Drive power: 53 KW

- Module 25

- max. hob speed 250 rpm

- Hob nominal diameter 380/420 mm

- max. hob diameter 500 mm

- -max. hob face width 90/120/160 mm

- max. cutter head swivel angle +/- 25°

- max. ring height of the workpiece to be machined 500 mm

- max. ring thickness of the workpiece to be machined 400 mm

- Index milling head IFK4.21

- Quick cutter head change thanks to simplified interface

- Available with oil, emulsion and air cooling

- Drive power: 53 KW

- Module 30

- max. hob diameter 520 mm

- min. root diameter of the hob 360 mm

- max. hob face width 120 mm

- max. ring height of the workpiece to be machined incl. clamping devices 1000 mm

- max. ring thickness of the workpiece to be machined 500 mm

Gear hobbing head HH 450 DD

- Drive power: 53 KW

- Module 24/30

- max. hob speed 250 rpm

- max. hob diameter 320 mm

- max. hob length 440 mm

- max. tangential distance 300mm

- max. tangential speed 500 mm/min

Gear hobbing head HH 450 DD

- Less torsion in the hob arbor thanks to torque introduction from both sides

- Optimum interfering contour

- Available with oil, emulsion and air cooling

- Adjustable coolant nozzle via control panel

- Drive power: 102 KW

- Module 30

- max. hob speed 275 rpm

- max. hob diameter 450 mm

- max. hob length 600 mm

- max. tangential distance 450 mm

Gear hobbing head FK4.2

- Drive power: 70 KW

- Module 30/40

- max. hob speed 250 rpm

- max. hob diameter 450 mm

- max. hob length 700 mm

- max. tangential distance 450 mm

- max. tangential speed 500 mm/min

Gear hobbing head HH 500 DD

- Optimum interfering contour (suitable for workpieces up to 16 meters in diameter)

- Available with oil, emulsion and air cooling

- Adjustable coolant nozzle via control panel

- Drive power: 110 KW

- Module 50/60

- max. hob speed 250 rpm

- max. hob diameter 520 mm

- max. hob length 800 mm

- max. tangential distance 600 mm

- Index milling head IFK4.11

- Quick cutter head change thanks to simplified interface

- Available with oil, emulsion and air cooling

- Drive power: 53 KW

- Module 25

- max. hob speed 250 rpm

- Hob nominal diameter 380/420 mm

- max. hob diameter 500 mm

- -max. hob face width 90/120/160 mm

- max. cutter head swivel angle +/- 25°

- max. ring height of the workpiece to be machined 500 mm

- max. ring thickness of the workpiece to be machined 400 mm

- Index milling head IFK4.21

- Quick cutter head change thanks to simplified interface

- Available with oil, emulsion and air cooling

- Drive power: 53 KW

- Module 30

- max. hob diameter 520 mm

- min. root diameter of the hob 360 mm

- max. hob face width 120 mm

- max. ring height of the workpiece to be machined incl. clamping devices 1000 mm

- max. ring thickness of the workpiece to be machined 500 mm

Gear hobbing head HH 450 DD

- Drive power: 53 KW

- Module 24/30

- max. hob speed 250 rpm

- max. hob diameter 320 mm

- max. hob length 440 mm

- max. tangential distance 300mm

- max. tangential speed 500 mm/min

Gear hobbing head HH 450 DD

- Less torsion in the hob arbor thanks to torque introduction from both sides

- Optimum interfering contour

- Available with oil, emulsion and air cooling

- Adjustable coolant nozzle via control panel

- Drive power: 102 KW

- Module 30

- max. hob speed 275 rpm

- max. hob diameter 450 mm

- max. hob length 600 mm

- max. tangential distance 450 mm

Gear hobbing head FK4.2

- Drive power: 70 KW

- Module 30/40

- max. hob speed 250 rpm

- max. hob diameter 450 mm

- max. hob length 700 mm

- max. tangential distance 450 mm

- max. tangential speed 500 mm/min

Gear hobbing head HH 500 DD

- Optimum interfering contour (suitable for workpieces up to 16 meters in diameter)

- Available with oil, emulsion and air cooling

- Adjustable coolant nozzle via control panel

- Drive power: 110 KW

- Module 50/60

- max. hob speed 250 rpm

- max. hob diameter 520 mm

- max. hob length 800 mm

- max. tangential distance 600 mm

- Index milling head IFK4.11

- Quick cutter head change thanks to simplified interface

- Available with oil, emulsion and air cooling

- Drive power: 53 KW

- Module 25

- max. hob speed 250 rpm

- Hob nominal diameter 380/420 mm

- max. hob diameter 500 mm

- -max. hob face width 90/120/160 mm

- max. cutter head swivel angle +/- 25°

- max. ring height of the workpiece to be machined 500 mm

- max. ring thickness of the workpiece to be machined 400 mm

- Index milling head IFK4.21

- Quick cutter head change thanks to simplified interface

- Available with oil, emulsion and air cooling

- Drive power: 53 KW

- Module 30

- max. hob diameter 520 mm

- min. root diameter of the hob 360 mm

- max. hob face width 120 mm

- max. ring height of the workpiece to be machined incl. clamping devices 1000 mm

- max. ring thickness of the workpiece to be machined 500 mm

Impressions

LC 4000

LC 4000 - Profile milling

LC 4000

LC 4000 - Gear hobbing

LC 4000

LC 4000 - Profile milling

LC 6000

LC 6000 - Profile milling

Module 50 mm

LC 6000

LC 6000 with complete paneling

LC 6000

LC 6000 - Machining of slewing bearings

Index milling head IFK 4.11

LC 4000

LC 4000 - Profile milling

LC 4000

LC 4000 - Gear hobbing

LC 4000

LC 4000 - Profile milling

LC 6000

LC 6000 - Profile milling

Module 50 mm

LC 6000

LC 6000 with complete paneling

LC 6000

LC 6000 - Machining of slewing bearings

Index milling head IFK 4.11

LC 4000

LC 4000 - Profile milling

LC 4000

LC 4000 - Gear hobbing

LC 4000

LC 4000 - Profile milling

LC 6000

LC 6000 - Profile milling

Module 50 mm

LC 6000

LC 6000 with complete paneling

LC 6000

LC 6000 - Machining of slewing bearings

Index milling head IFK 4.11

Customer projects

Not an off-the-shelf machine: LC 4000 for HMC

With the LC 4000, Liebherr is breaking new ground in the production of large gears and combining different hobbing methods on a highly efficient machine for the American gear specialist.

Innovative gear cutting center for hobbing, profile millling and 4-axis milling

The machine has a new type of direct-drive cutter head as well as an additional finger milling head for external and internal gears with its own main column. This enables machining with hobbing, profile milling, and 4-axis milling on a single machine which is optimal for the manufacture of herringbone and double helical gears.

Technical data

| Module | 24.00 - 60.00 mm |

| Workpiece diameter | 1,500 - 12,000 mm |

| Variants | LC 1500 | LC 2000 | LC 2500 | LC 3000 | LC 4500 | LC 6000 | LC 8000 | LC 10000 | LC 12000 |

|---|---|---|---|---|---|---|---|---|---|

| Module (mm) | 24.00 / 30.00 | 24.00 / 30.00 | 30.00 / 40.00 | 30.00 / 40.00 | 30.00 / 40.00 | 30.00 / 40.00 | 50.00 / 60.00 | 50.00 / 60.00 | 50.00 / 60.00 |

| Workpiece diameter (mm) | 1,500 | 2,000 | 2,500 | 3,000 | 4,500 | 6,000 | 8,000 | 10,000 | 12,000 |

| Axial travel (mm) | 1,200 / 1,800 | 1,200 / 2,700 | 1,200 / 2,700 | 1,200 / 2,700 | 1,200 / 2,700 | 1,200 / 2,700 | 1,200 / 2,700 | 1,200 / 2,700 | 1,200 / 2,700 |

Discover more products from Liebherr-Verzahntechnik GmbH:

Energy and resource efficiency

- Regenerative drive technology

- Use of efficient control cabinet coolers

- LED technology lighting

- Coolant supply and

- preparation with speed-controlled pumps