Examples of uses for mineral raw materials

Moisture determination in sand

Installed in the outlet of a silo, the Liebherr moisture measurement system determines the moisture continuously or, if required, in batches.

Moisture determination in sand

Installed above a conveyor belt of a concrete mixing plant, the sensor glides over the sand by means of sliding shoe carriages. The dead weight of the slide creates a uniform contact pressure; this is advantageous for determining the moisture.

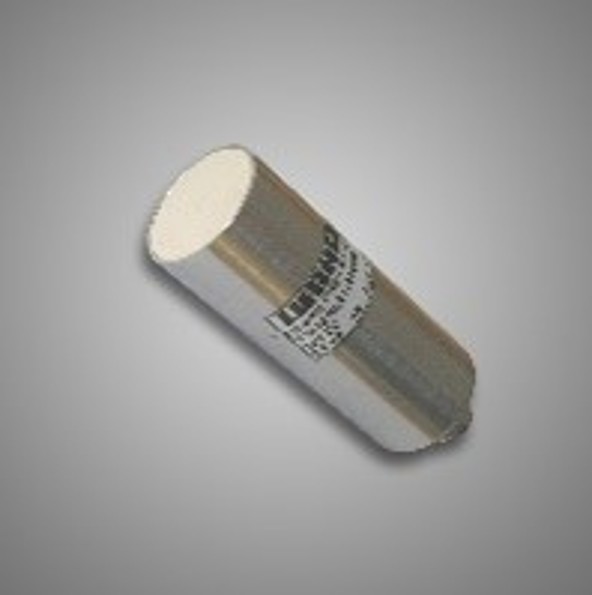

Moisture determination in iron ore

The Liebherr moisture measuring sensor is also convincing in extremely abrasive materials.

Moisture determination in ceramic powder

The FMS II moisture measurement system enables efficient editing directly during operation. Before further processing, the humidity is measured and the measured values are transmitted to the higher-level control.

Moisture determination in quartz sand

Whether installed directly on the quartz sand or mounted under the conveyor belt, the humidity sensor from Liebherr always determines the exact moisture in the sand.

Moisture determination in shards/broken glass

From old to new. Used glass is returned to the cycle and sparkles in new splendour as glass containers in any shape.

Moisture determination in excavated soil

Reliable moisture measurement with Liebherr sensors and associated evaluation unit in gravel, clay and also loam.

Moisture determination in clay in the brickworks

If the material flows are sometimes very uneven, the sliding shoe carriage can be weighted down with ballast.

This will give very good and reproducible results.

Use in sludge drying

To avoid under and over-drying, Liebherr moisture measurement determines the exact moisture in-line during the process. The measured values can be transferred directly to the dryer control.

Moisture determination in sand

Installed in the outlet of a silo, the Liebherr moisture measurement system determines the moisture continuously or, if required, in batches.

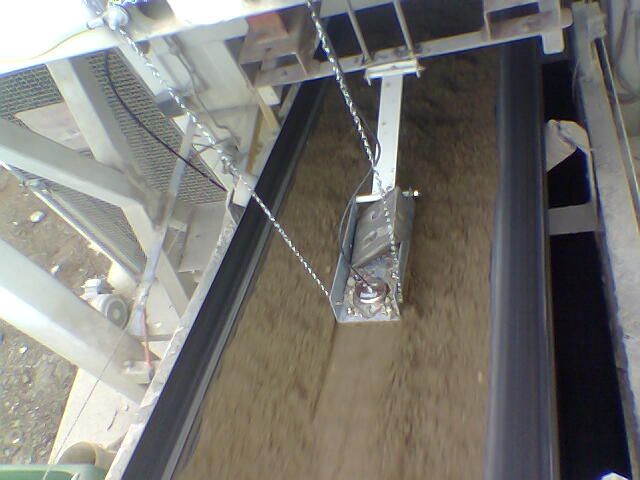

Moisture determination in sand

Installed above a conveyor belt of a concrete mixing plant, the sensor glides over the sand by means of sliding shoe carriages. The dead weight of the slide creates a uniform contact pressure; this is advantageous for determining the moisture.

Moisture determination in iron ore

The Liebherr moisture measuring sensor is also convincing in extremely abrasive materials.

Moisture determination in ceramic powder

The FMS II moisture measurement system enables efficient editing directly during operation. Before further processing, the humidity is measured and the measured values are transmitted to the higher-level control.

Moisture determination in quartz sand

Whether installed directly on the quartz sand or mounted under the conveyor belt, the humidity sensor from Liebherr always determines the exact moisture in the sand.

Moisture determination in shards/broken glass

From old to new. Used glass is returned to the cycle and sparkles in new splendour as glass containers in any shape.

Moisture determination in excavated soil

Reliable moisture measurement with Liebherr sensors and associated evaluation unit in gravel, clay and also loam.

Moisture determination in clay in the brickworks

If the material flows are sometimes very uneven, the sliding shoe carriage can be weighted down with ballast.

This will give very good and reproducible results.

Use in sludge drying

To avoid under and over-drying, Liebherr moisture measurement determines the exact moisture in-line during the process. The measured values can be transferred directly to the dryer control.

Moisture determination in sand

Installed in the outlet of a silo, the Liebherr moisture measurement system determines the moisture continuously or, if required, in batches.

Moisture determination in sand

Installed above a conveyor belt of a concrete mixing plant, the sensor glides over the sand by means of sliding shoe carriages. The dead weight of the slide creates a uniform contact pressure; this is advantageous for determining the moisture.

Moisture determination in iron ore

The Liebherr moisture measuring sensor is also convincing in extremely abrasive materials.

Moisture determination in ceramic powder

The FMS II moisture measurement system enables efficient editing directly during operation. Before further processing, the humidity is measured and the measured values are transmitted to the higher-level control.

Moisture determination in quartz sand

Whether installed directly on the quartz sand or mounted under the conveyor belt, the humidity sensor from Liebherr always determines the exact moisture in the sand.

Moisture determination in shards/broken glass

From old to new. Used glass is returned to the cycle and sparkles in new splendour as glass containers in any shape.

Moisture determination in excavated soil

Reliable moisture measurement with Liebherr sensors and associated evaluation unit in gravel, clay and also loam.

Moisture determination in clay in the brickworks

If the material flows are sometimes very uneven, the sliding shoe carriage can be weighted down with ballast.

This will give very good and reproducible results.

Use in sludge drying

To avoid under and over-drying, Liebherr moisture measurement determines the exact moisture in-line during the process. The measured values can be transferred directly to the dryer control.

Components

Components