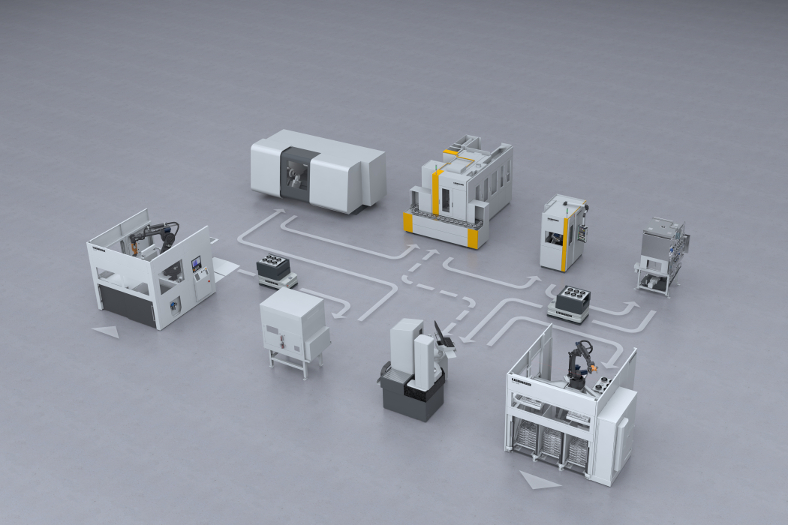

Weishaupt, headquartered in the Upper Swabian town of Schwendi, is a leading provider of burners, heat pumps, heating and condensing-boiler systems, energy recovery solutions, and facility automation. Since mid-2016 Weishaupt’s new burner casing production facility has operated using an automation solution provided by Liebherr-Verzahntechnik GmbH.