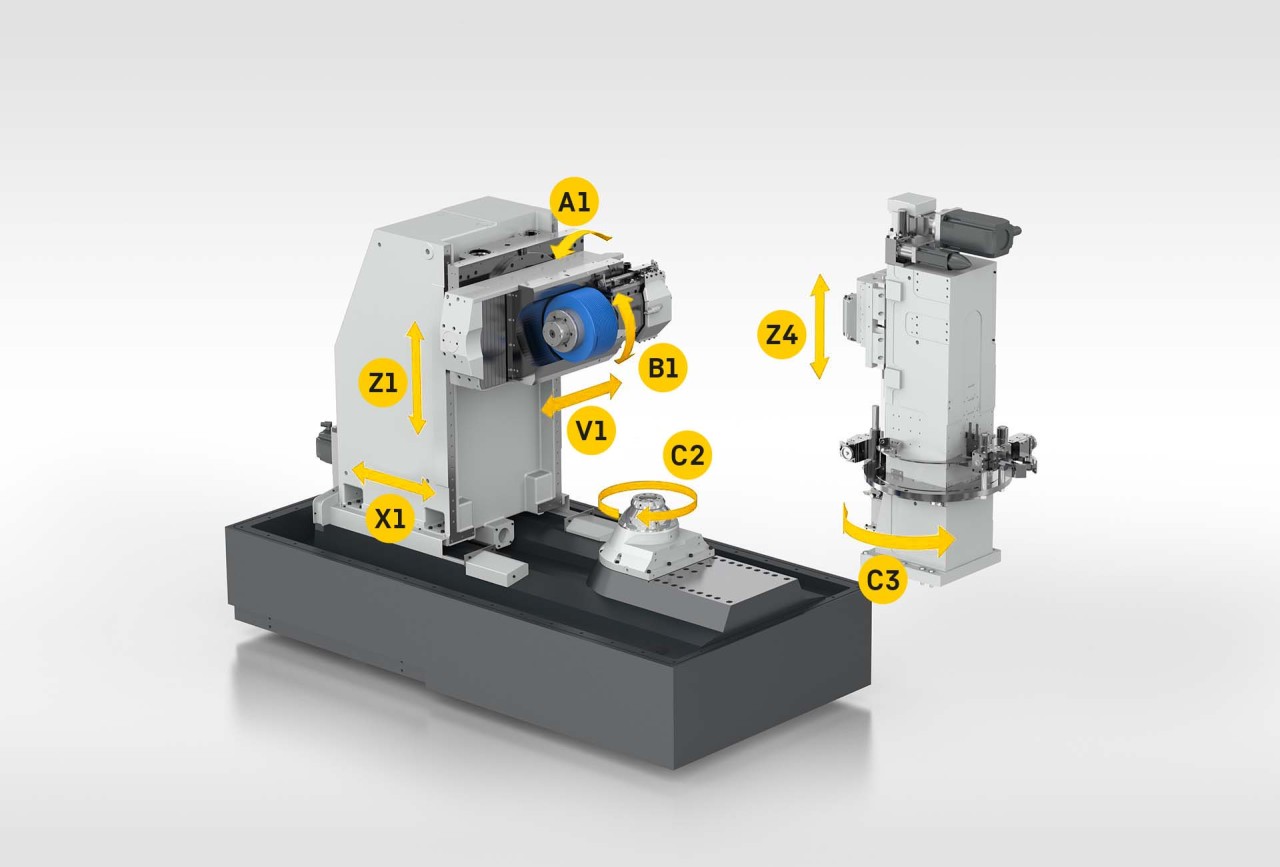

External and internal grinding heads

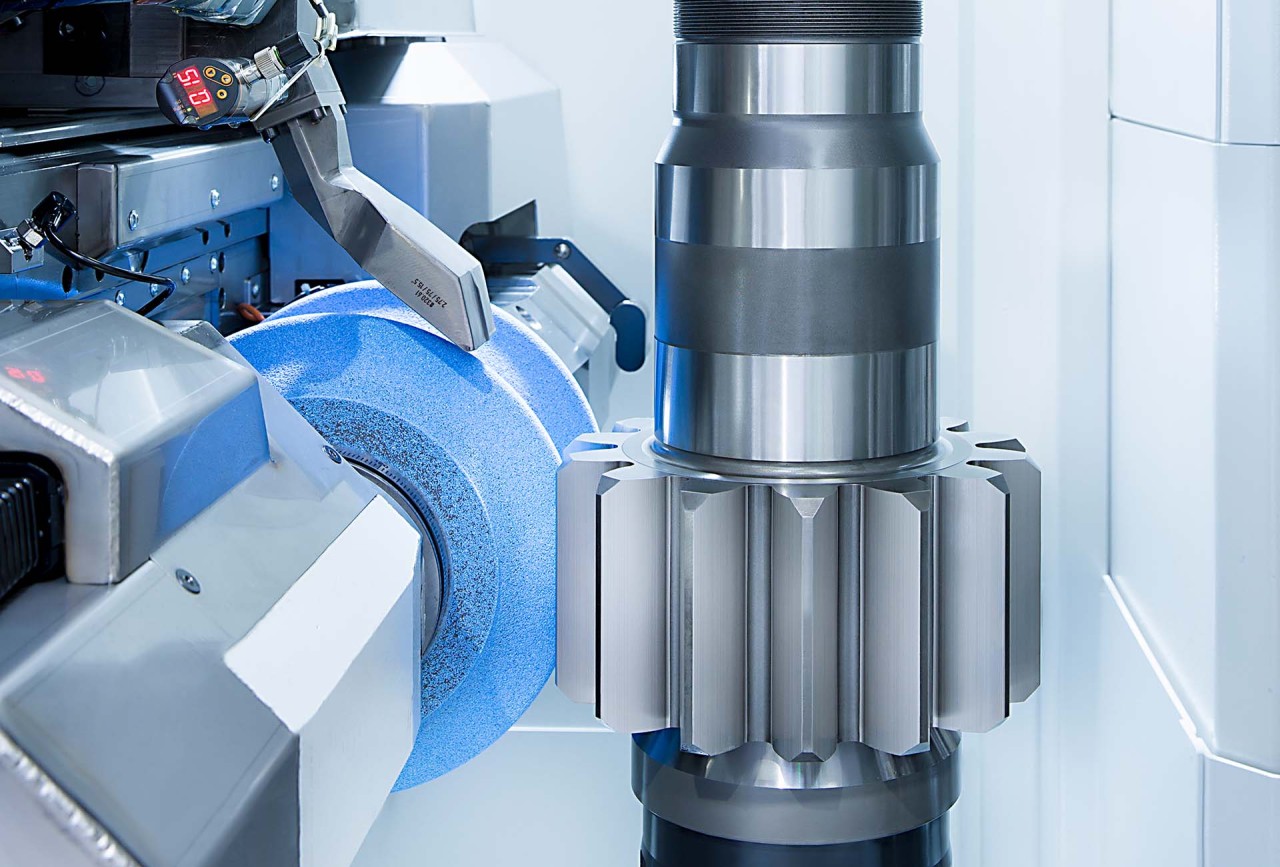

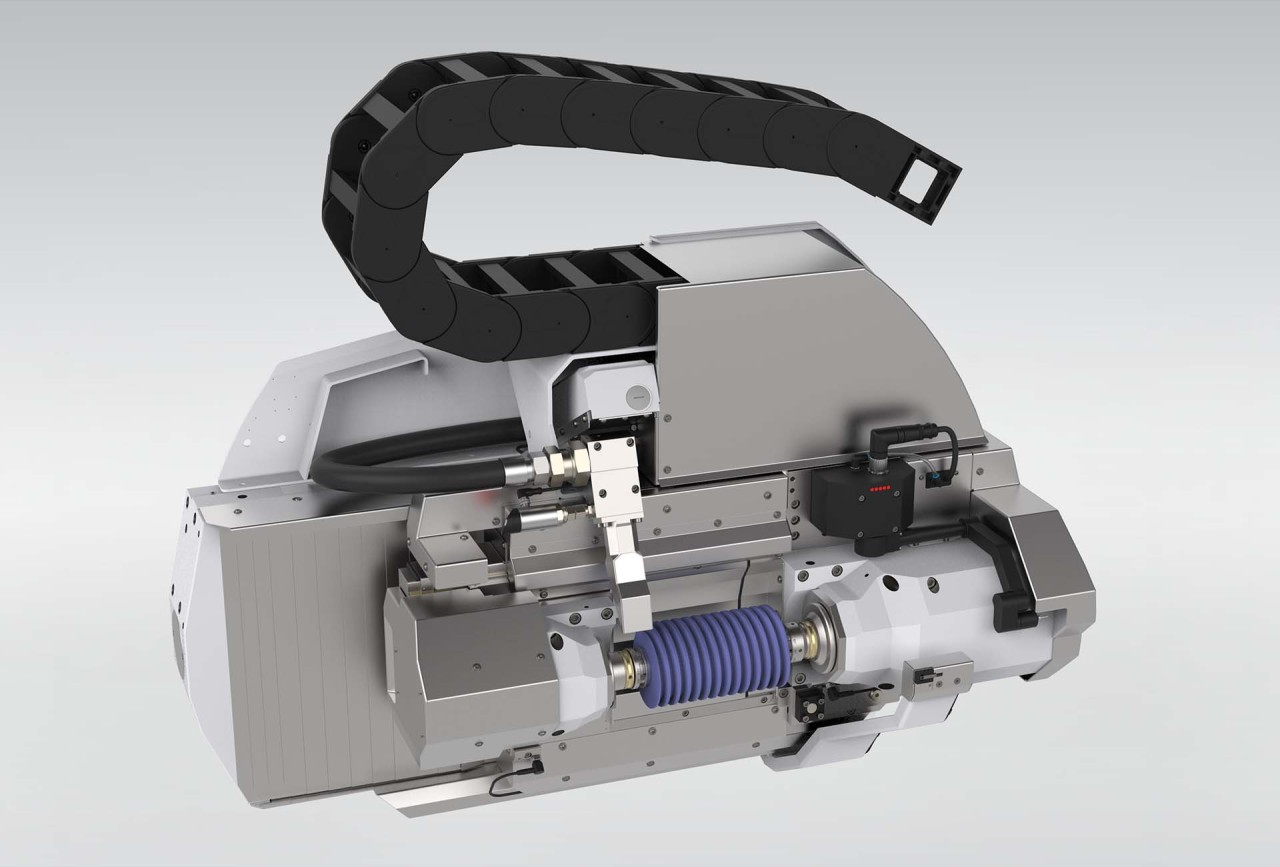

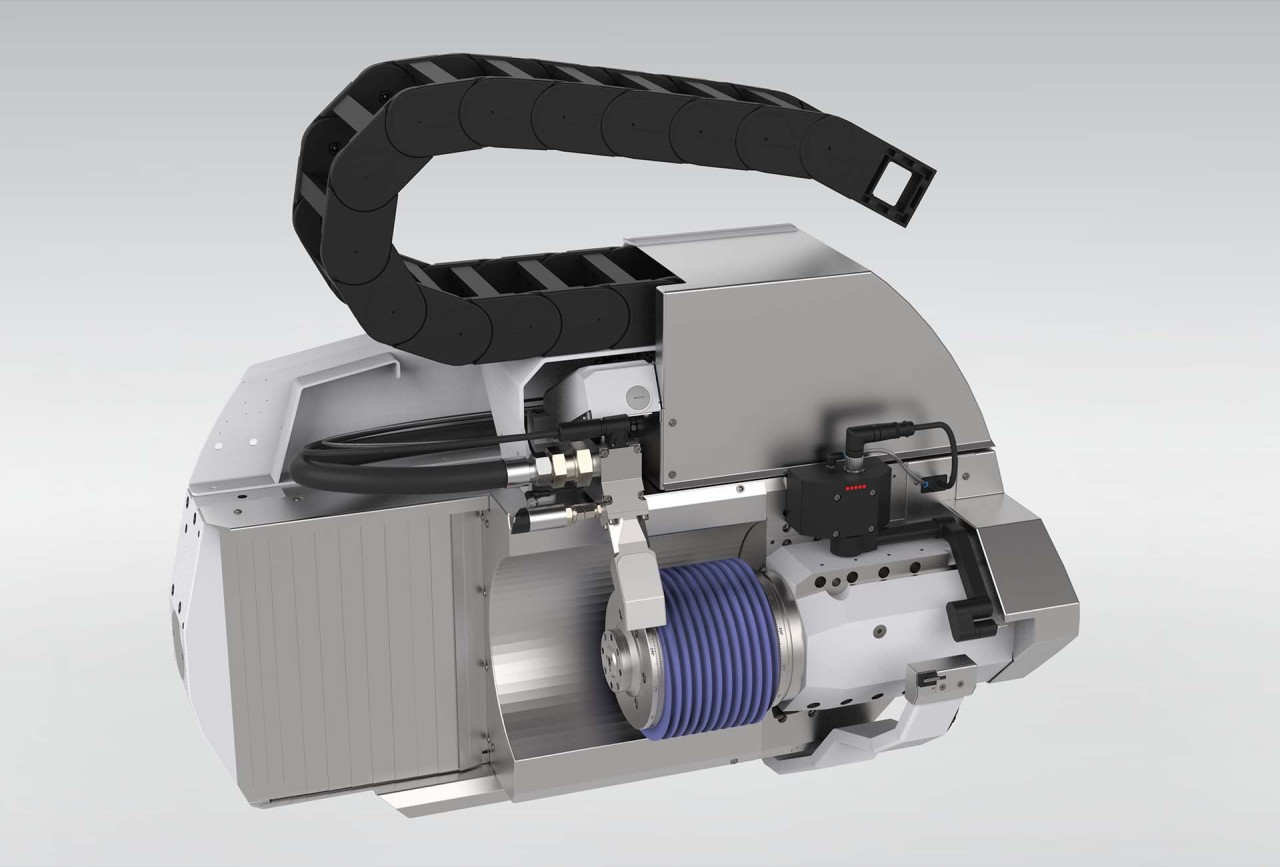

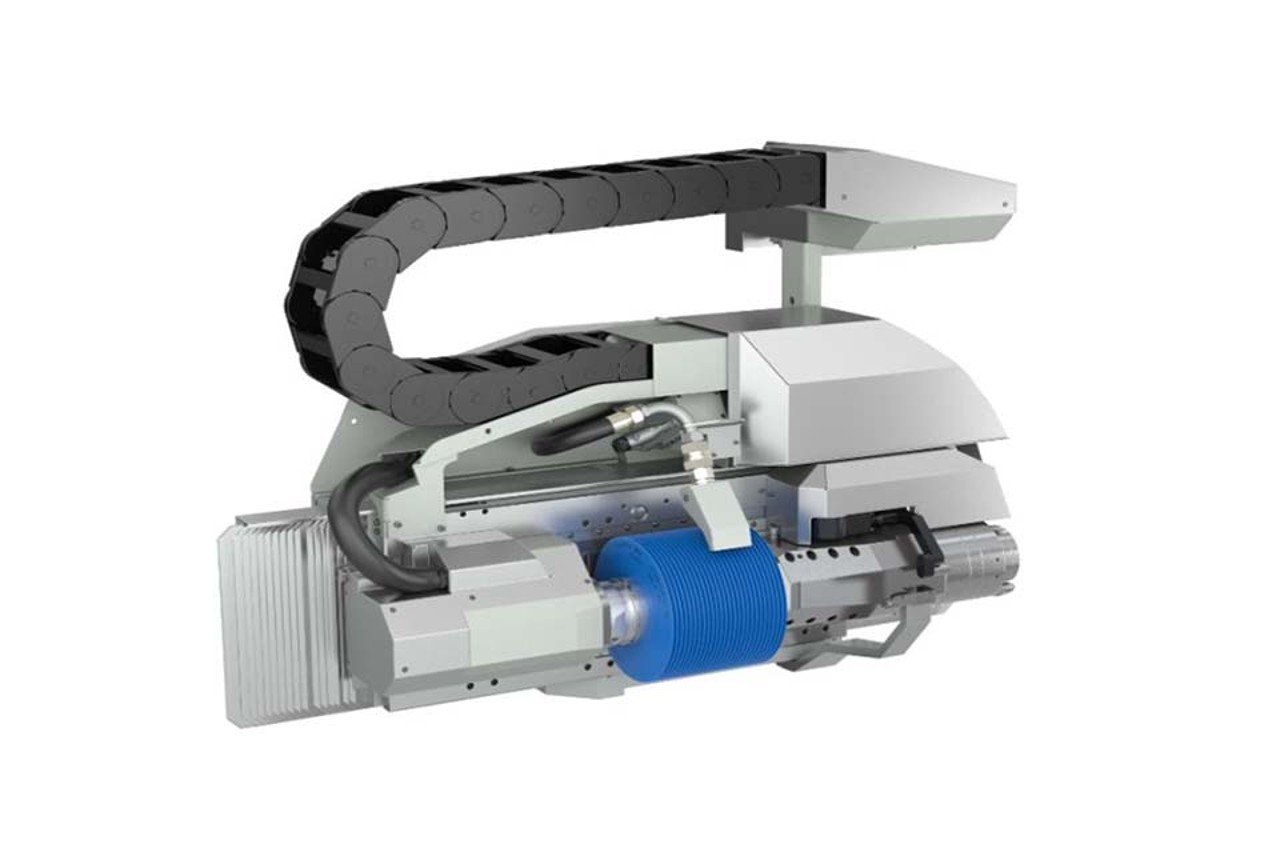

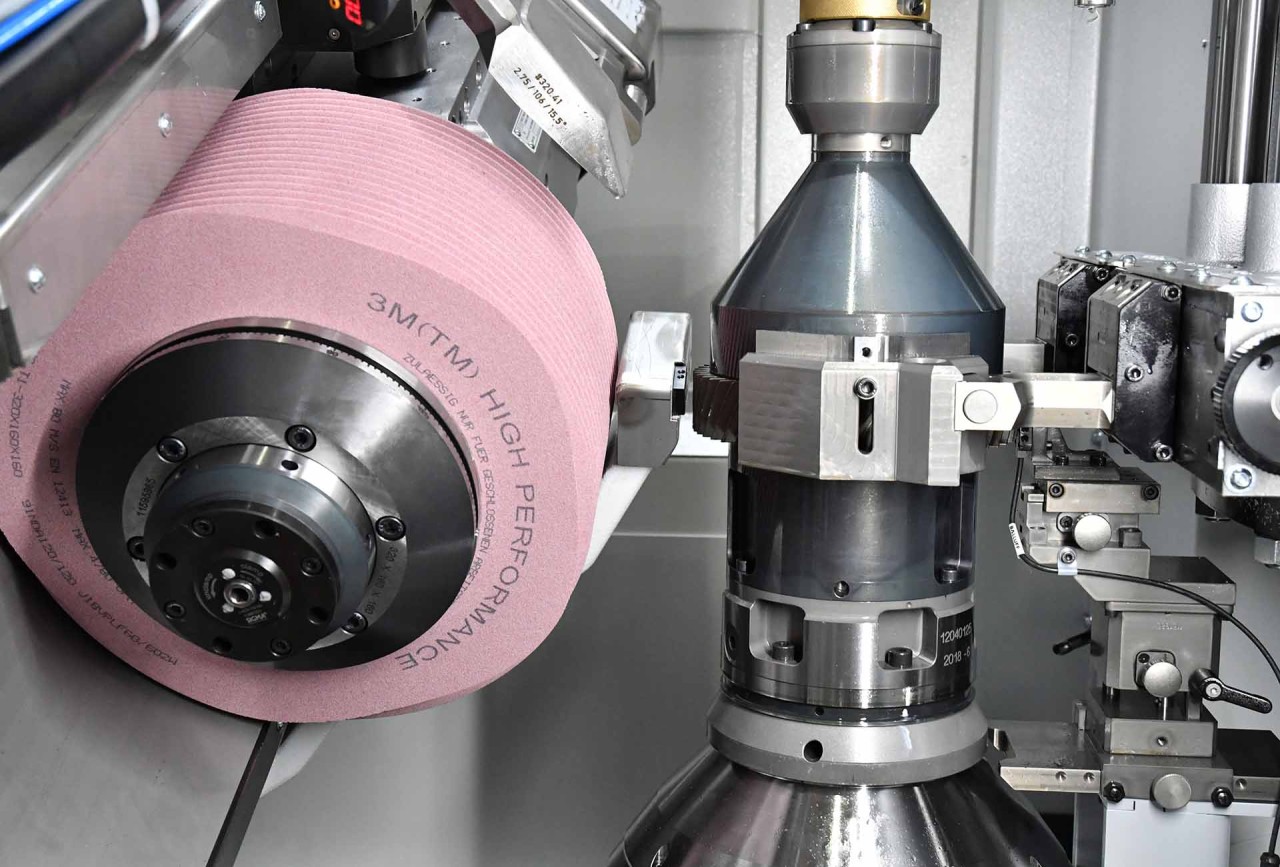

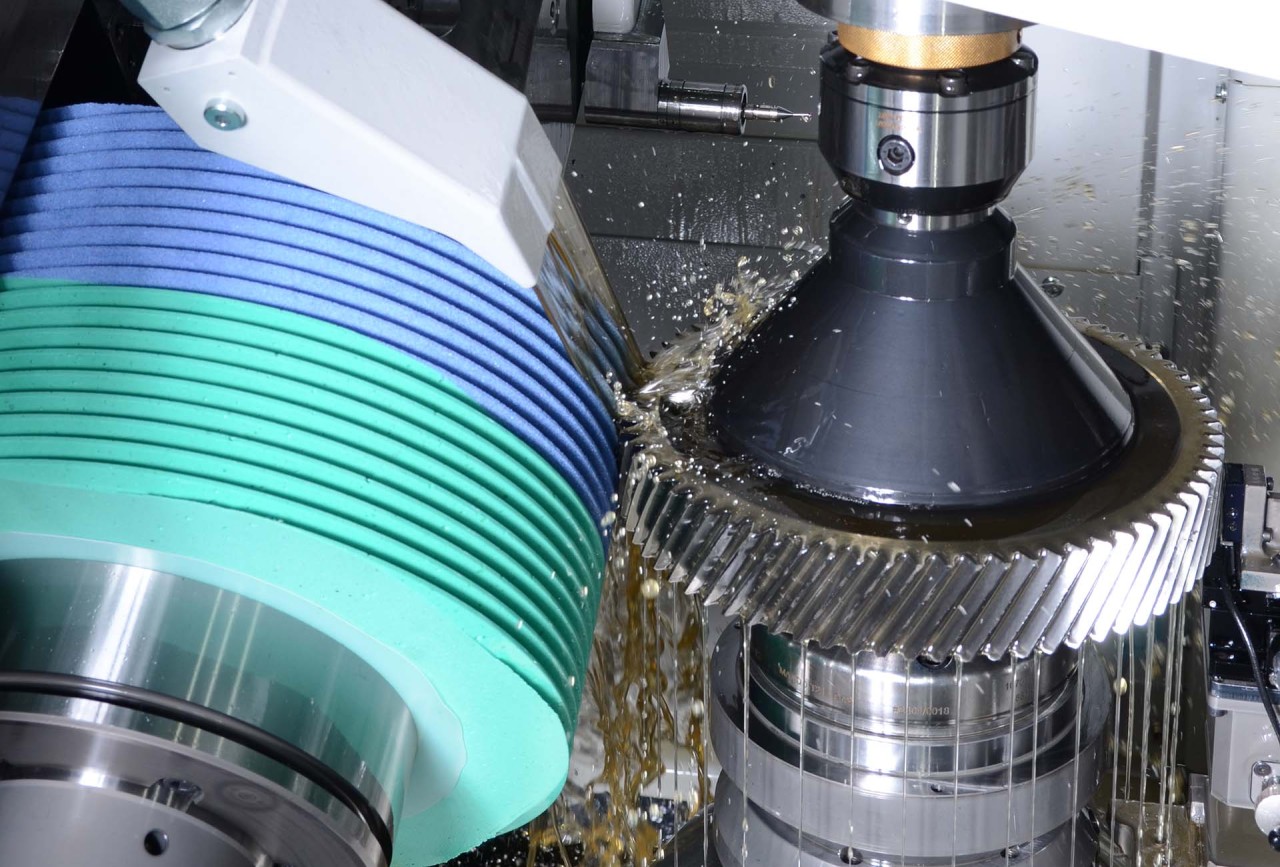

Process-optimized external grinding heads and internal grinding arms are available for the LGG. Balancing systems inside the spindle are used in both external grinding heads (GH 320 and GH 240 CB). On the GH 320 CB, the balancing system is integrated in the arbor.

High drive power and speeds are major advantages – for example, when using new grinding materials. The modern tool holding makes it possible to replace the grinding arbor quickly and easily.

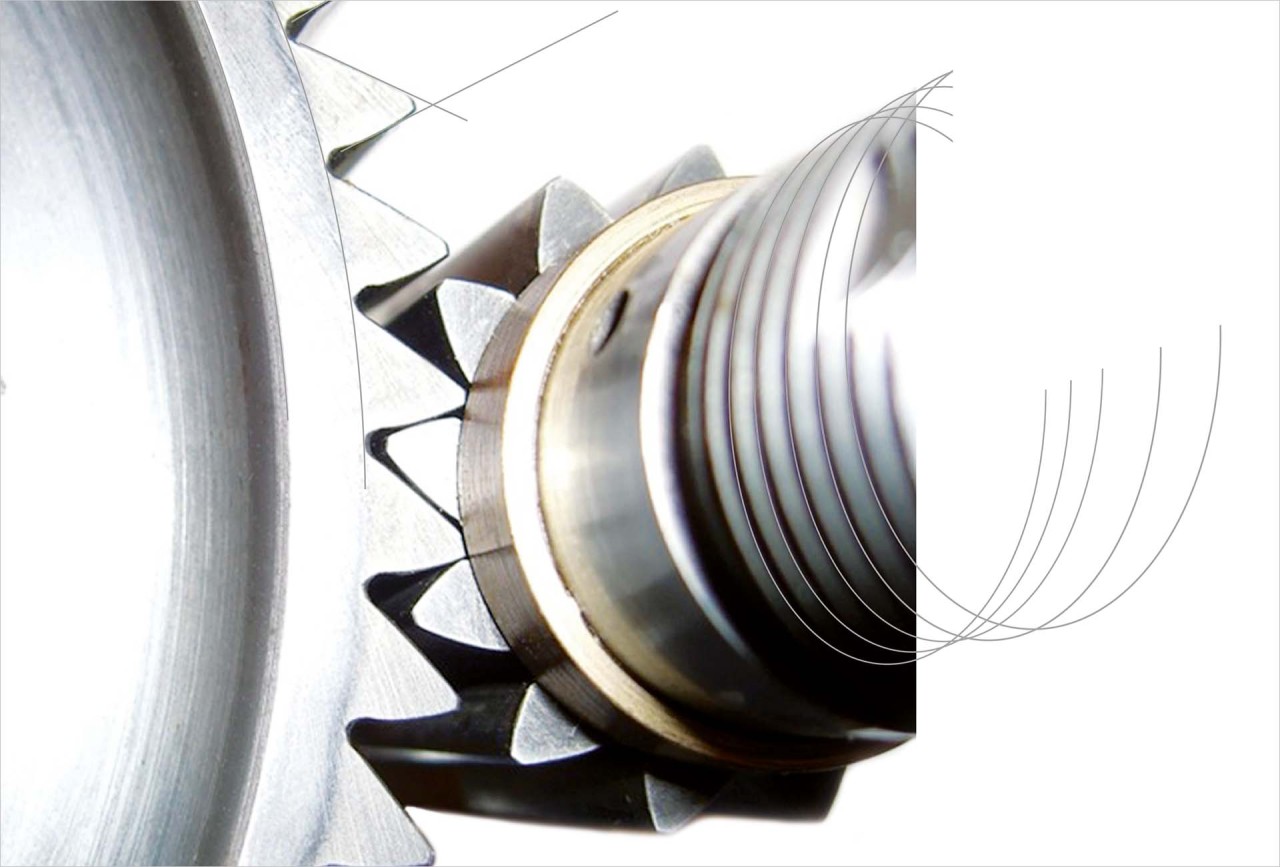

Small grinding tool diameters are available for collision-critical workpieces and for special tooth corrections.

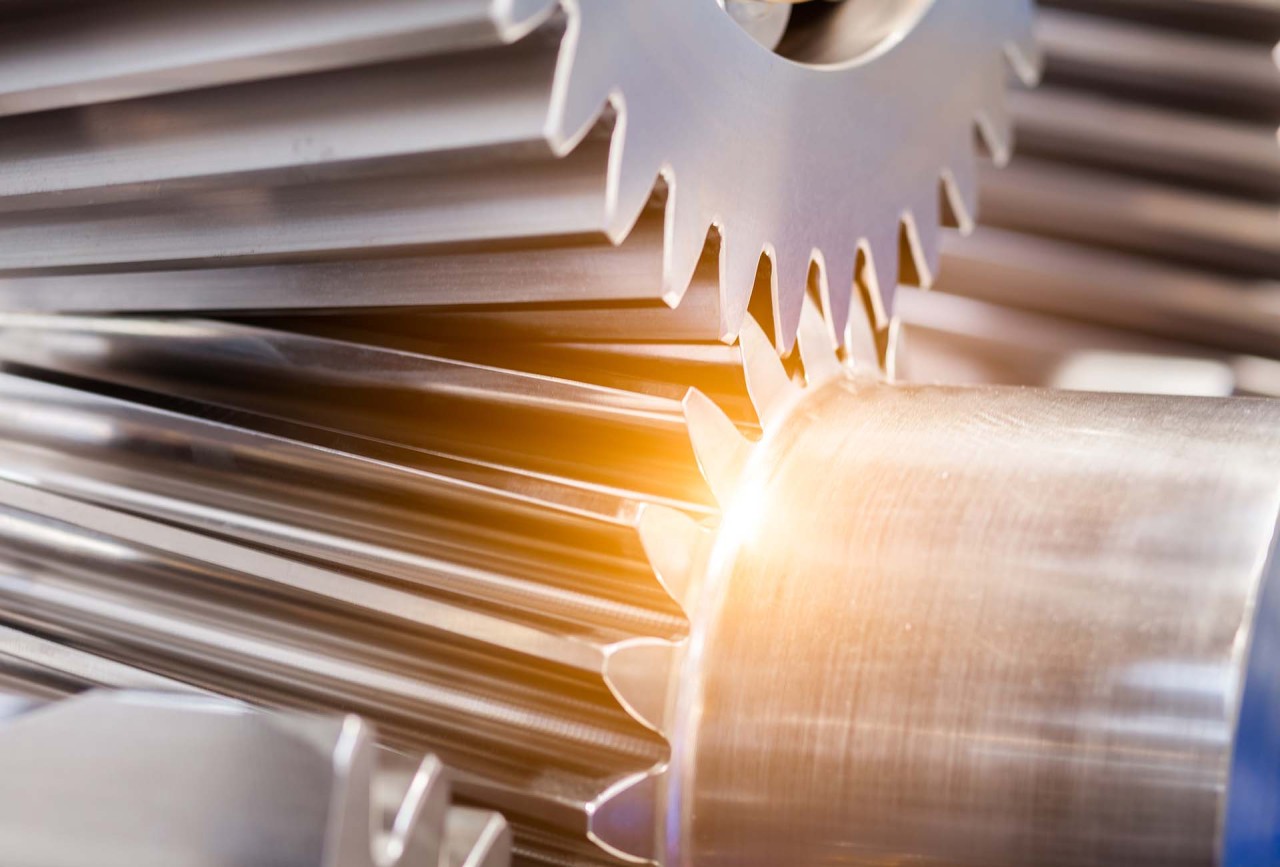

With the GH 320 CB grinding head, it is now also possible to efficiently grind optimal-quality workpieces up to module 14 mm.

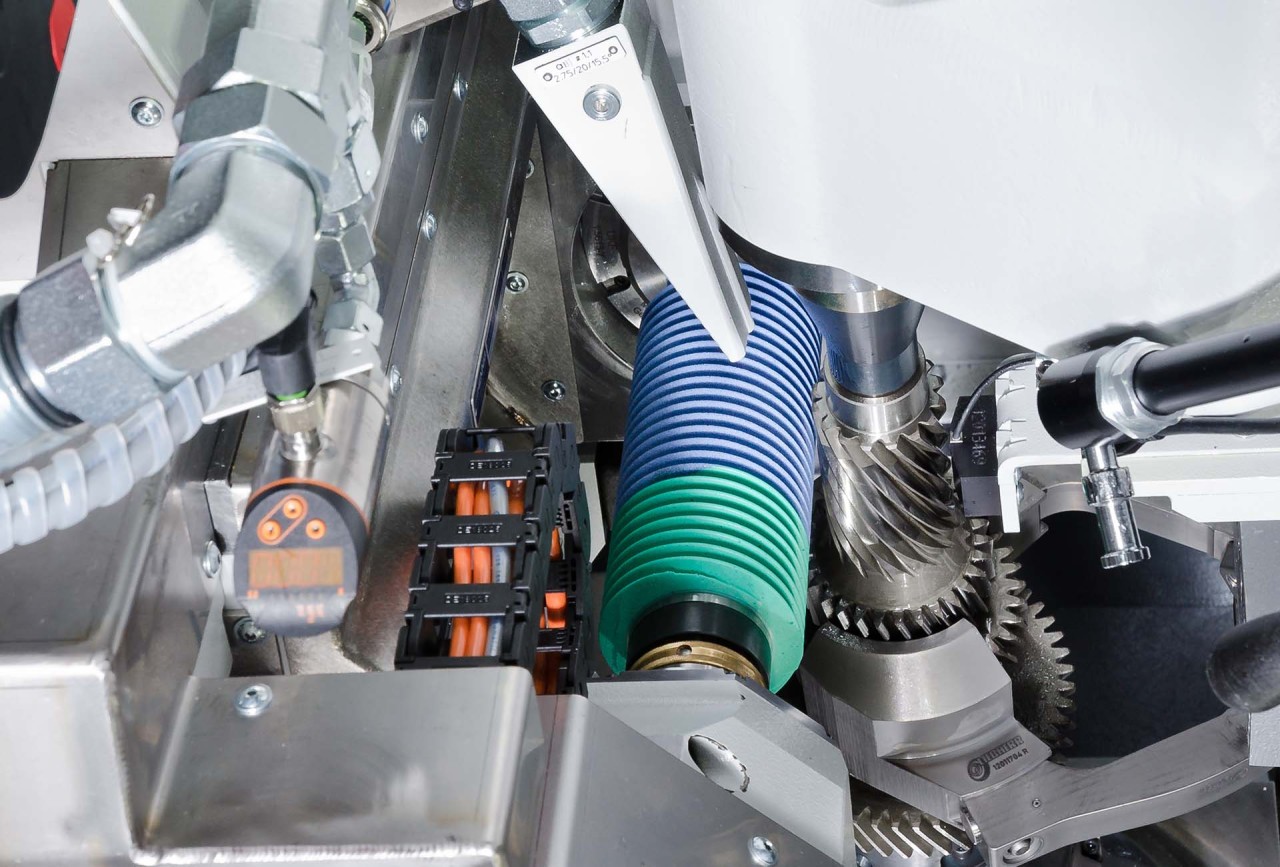

Fast and easy changeover

The adaptable internal grinding arms can be mounted quickly and easily on the external grinding head and are driven using the main drive. Other grinding heads can be provided on request.

In only 30minutes from external to internal grinding

Video

Generating grinding planetary gears, module 14, on the LGG 500 generating and profile grinding machine

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).Generating grinding with small tools

Integrated centrifugal device

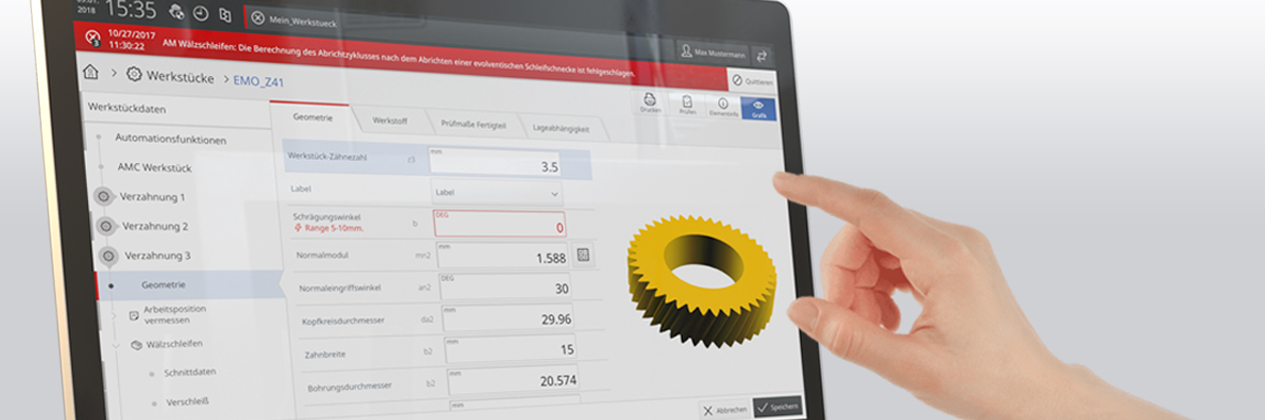

Automation

Technical data

| Variants | LGG 300 | LGG 380 | LGG 500 | LGG 700 M |

|---|