4 minutes | magazine 02/2018

The mobile crane redesigned

Liebherr unveiled a new 5-axle crane at its customer days 2018 – the LTM 1230-5.1 is extremely versatile, powerful, safe and efficient. And it has a surprising structural steel design.

Innovation with the same look

A case for the patent office

We're not reinventing the wheel. But we're rethinking everything else carefully. This is how we are preparing for the future. Our engineers have redesigned the basic structural steel construction, tailored it to current requirements and integrated the digital features of innovative Liebherr technologies. The result is a powerful, highly flexible mobile crane which delivers an excellent hoist height and range. The LTM 1230-5.1 sets the new benchmark in the 5-axle class.

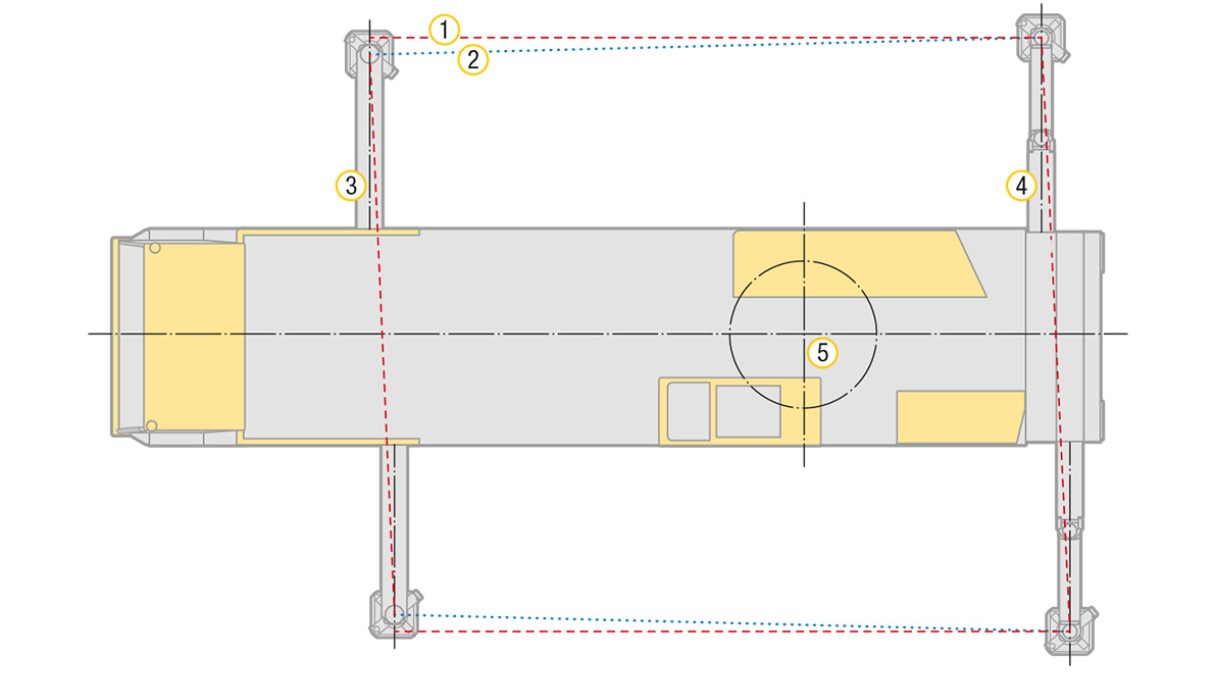

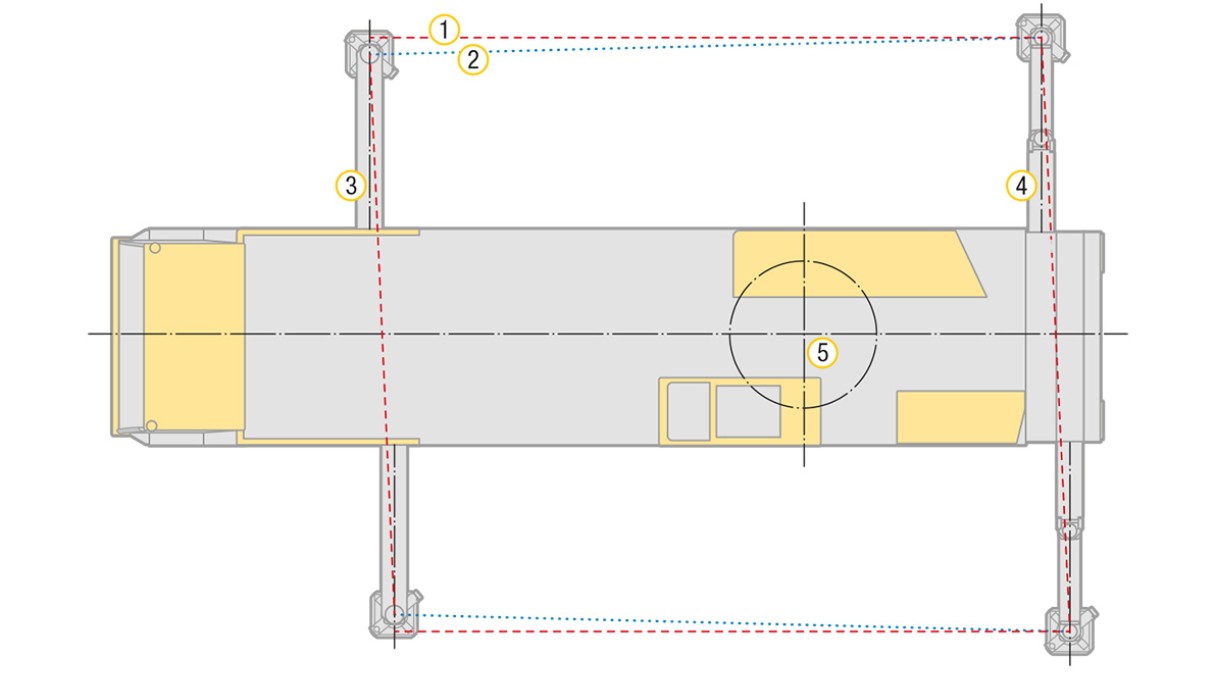

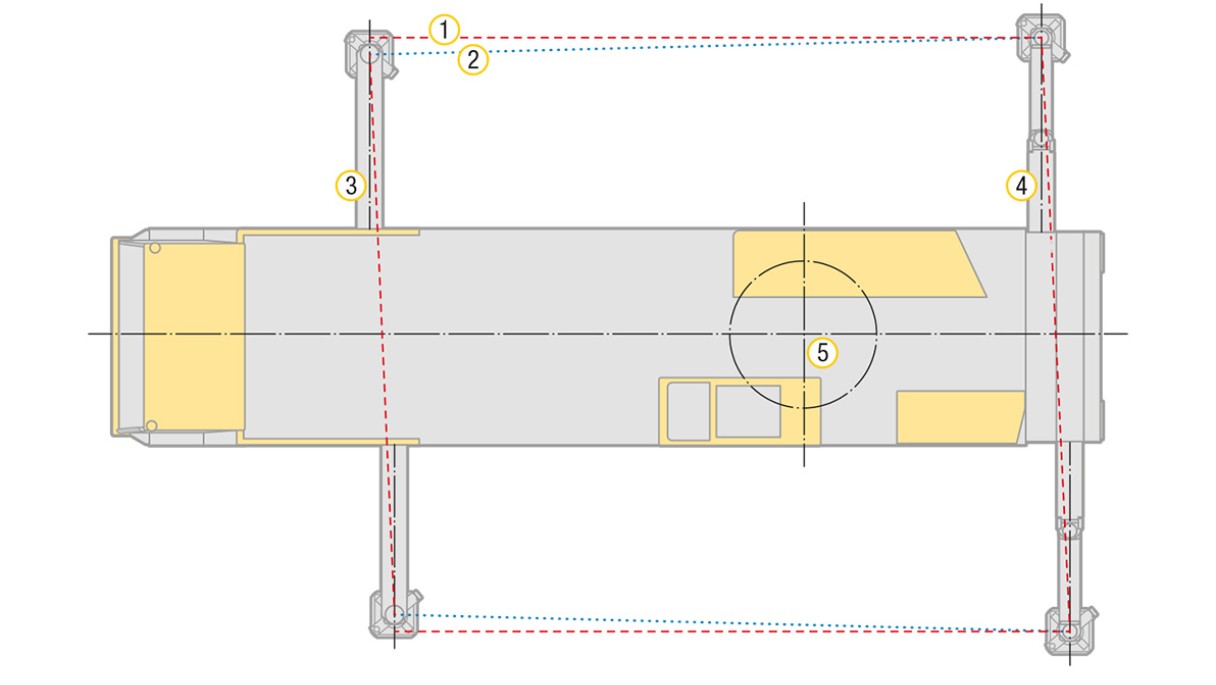

“We developed and used new ideas for the structural steelwork of the LTM 1230-5.1”, says Joachim Henkel and continues: “The front outriggers are single-stage, the rear ones are double-stage – unlike anything that has gone before.” He has been with the Design and Development Department in Ehingen for 28 years and has worked on the design of more than 40 crane models. He has been manager of the Statics Department since 2011. His team carries out complex calculations to improve the steel structure of Liebherr cranes.

Single and double-stage outriggers have been combined on a crane for the first time.

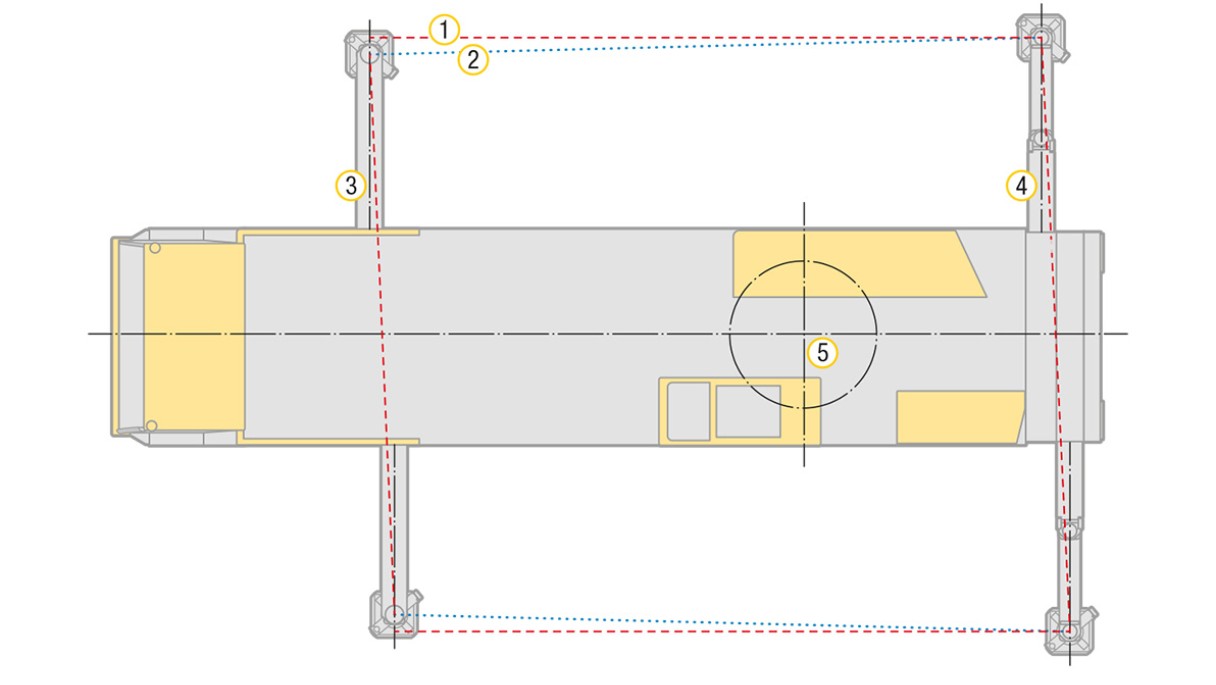

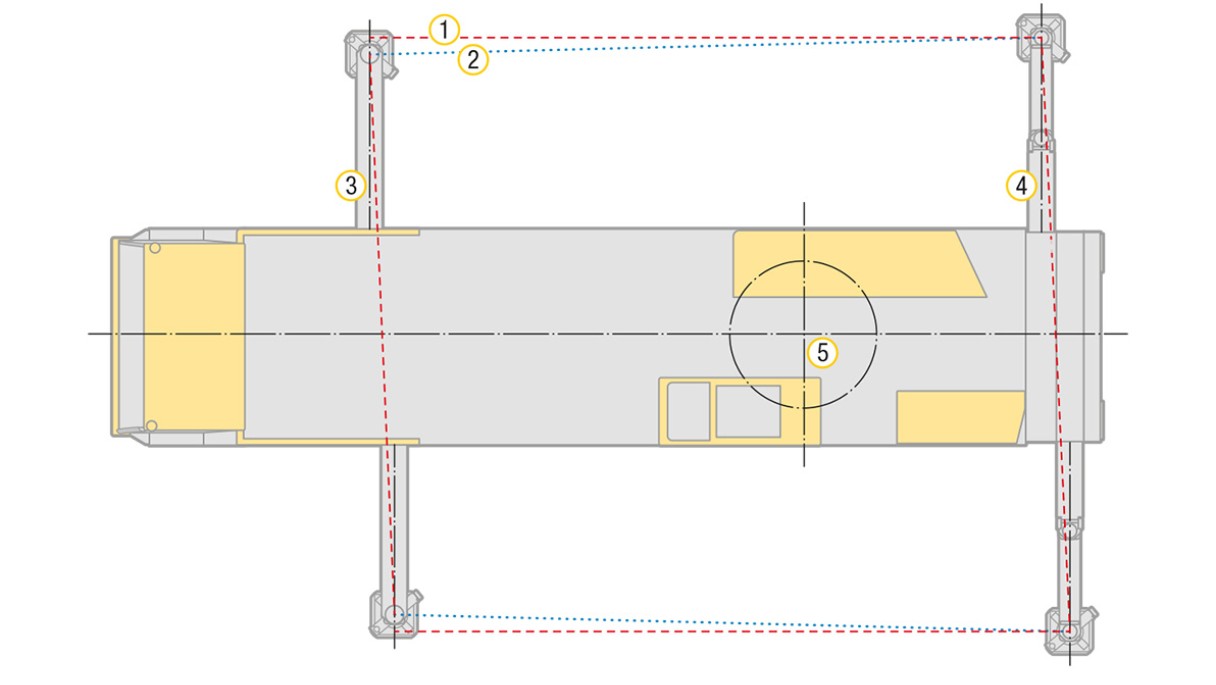

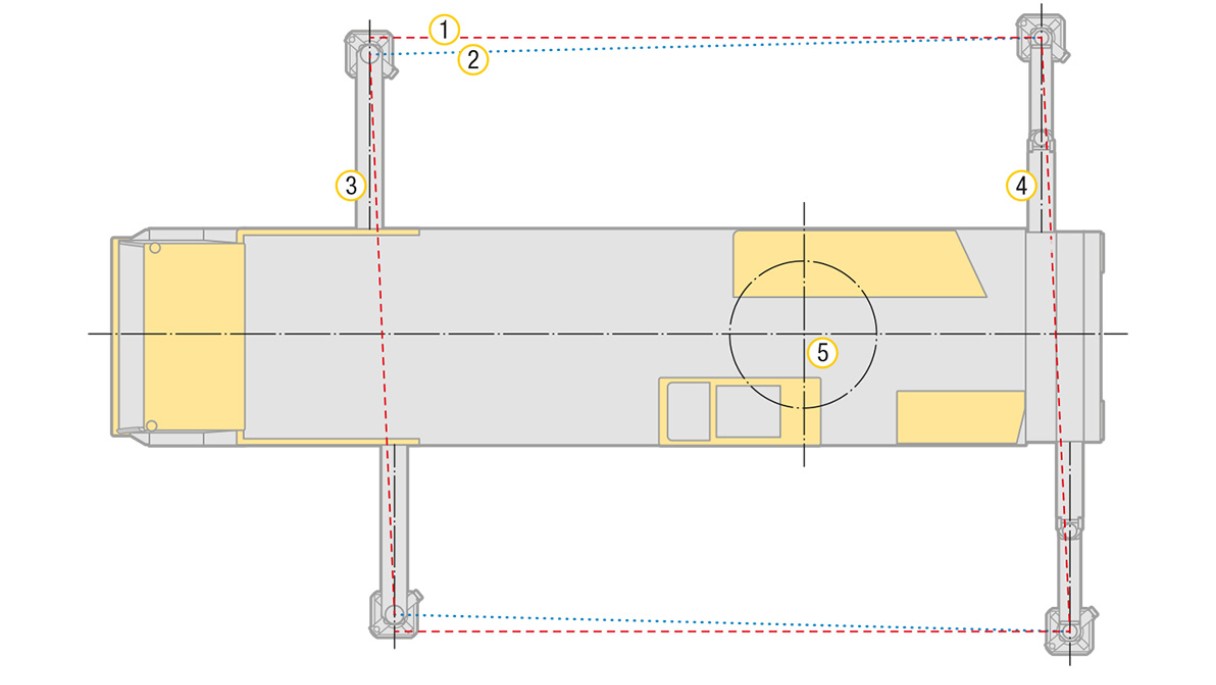

The support base overall is smaller than on the predecessor model LTM 1200-5.1 despite the new crane’s significantly higher lifting capacity and a longer boom. “This brings the crane closer to the load”. Henkel explains the concept on which a patent is pending: “We have designed the support base to have a trapezoidal shape. At the rear the maximum support width to the side is 8.1 metres and to the front 7.4 metres. With a working range of 360 degrees, this means that we have almost no reductions in lifting capacity compared to a rectangular support base with a support width of 8.1 metres to the front and rear.”

The single-stage outriggers at the front are lighter. This weight reduction can be used to extend the boom length. Furthermore, the single-stage outriggers feature greater rigidity. The extended rear supports, together with Liebherr’s VarioBase® deliver particularly high lifting capacities. We call the combination of the trapezoidal and variable support base “VarioBase Plus”.

Parallelogram-shaped support base

Find out more

Single telescoping outrigger

Find out more

Centre of rotation superstructure

Find out more

Trapezoidal support base

Find out more

Double telescoping outrigger

Find out more

Special effect – VarioBase®

VarioBase® makes the trapezoidal support base even more efficient. The multi-award-winning technology calculates the maximum lifting capacities in real time – based on the current support situation. The LTM 1230-5.1 delivers particularly high lifting capacities for hoists over the rear and the wide support base at the rear with part ballast, which are performed very frequently in practice. This can make a second ballast transport superfluous!

In summary: a real power pack

Finally, VarioBallast® completes the enormous increase in lifting capacity and flexibility – the radius of the 72-tonne ballast can be adjusted from 4.8 metres to 5.7 metres. Want a comparison? With the same ballast height compared to the predecessor model, the LTM 1200-5.1, the new 5-axle crane can on average hoist over 20 % more. That’s a significant increase!

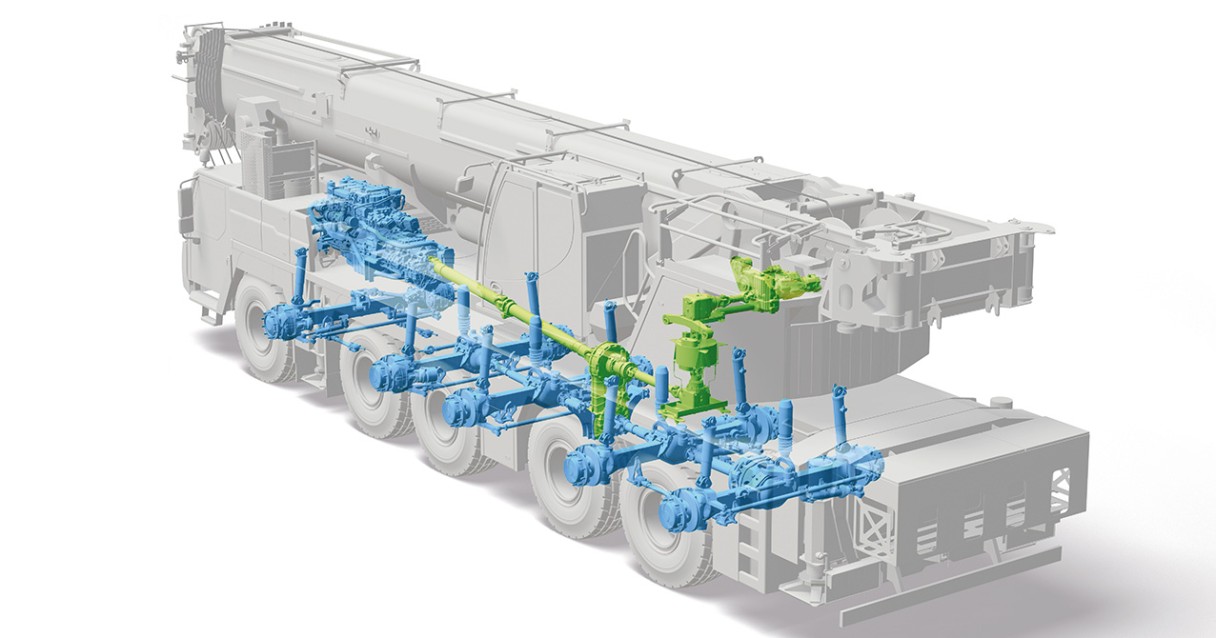

Green and powerful

The drive technology is ready to tackle the challenges of the future – the Liebherr diesel engine develops 400 kW whilst complying with stage V, including a particulate filter, to provide all the power you need. It transfers the power using the innovative ZF-TraXon gearbox, including ECOdrive, comfortable driving, noise reduction and the hill start aid. In addition, the time-tested single-engine concept with ECOmode from Liebherr reduces both fuel consumption and noise level.

The LTM 1230-5.1 is the fifth crane to feature the Liebherr single-engine concept.

This article was published in the UpLoad magazine 02|2018.