LC 300 - 500 / 700 M

Fully equipped. For every job.

Liebherr gear hobbing machines are optimally customized to the requirements of universal usability. Our high-performance gear hobbing machines are productive and machine in the highest quality.

Module - 3.50 - 16.00 mm

3.50 - 16.00 mm

Workpiece diameter - 300 - 700 mm

300 - 700 mm

Maximum flexibility

Maximized productivity

Improved ergonomics

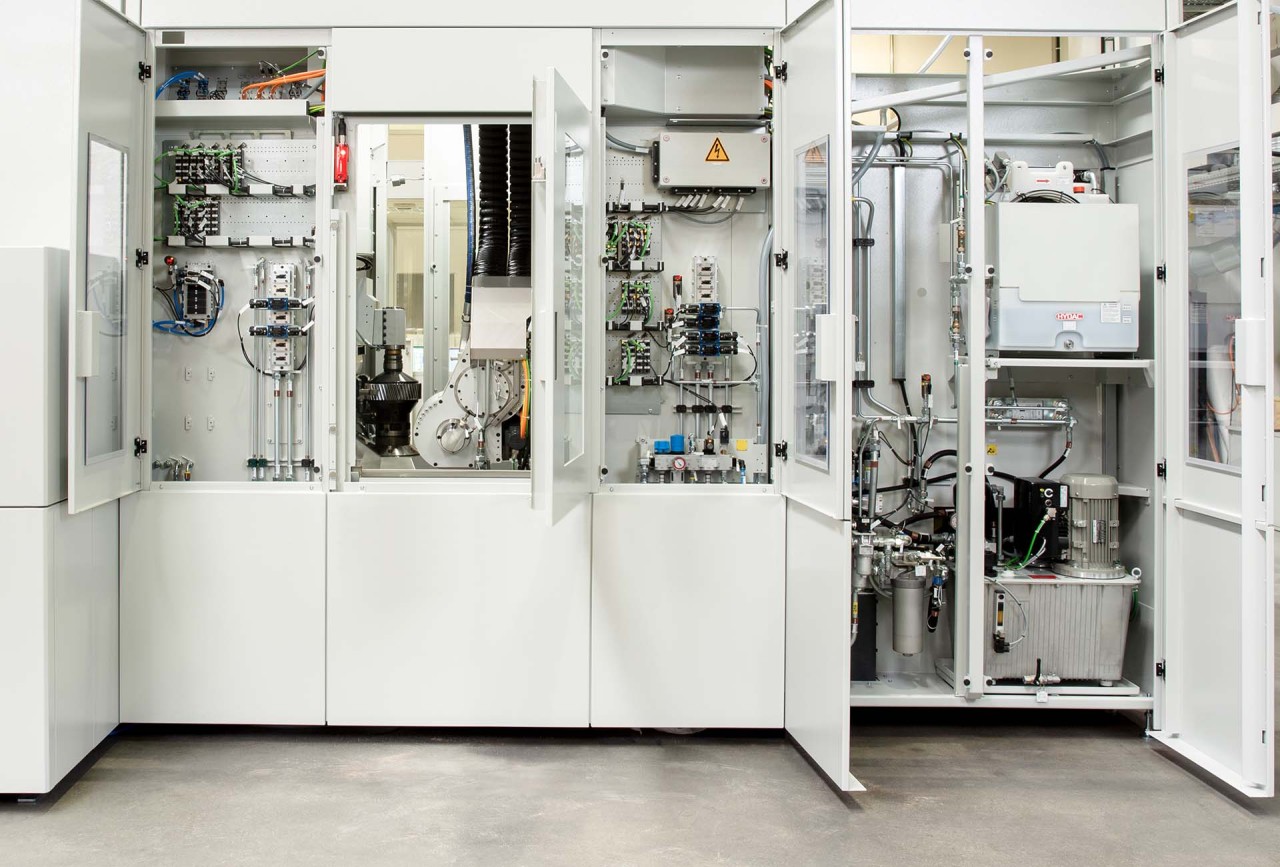

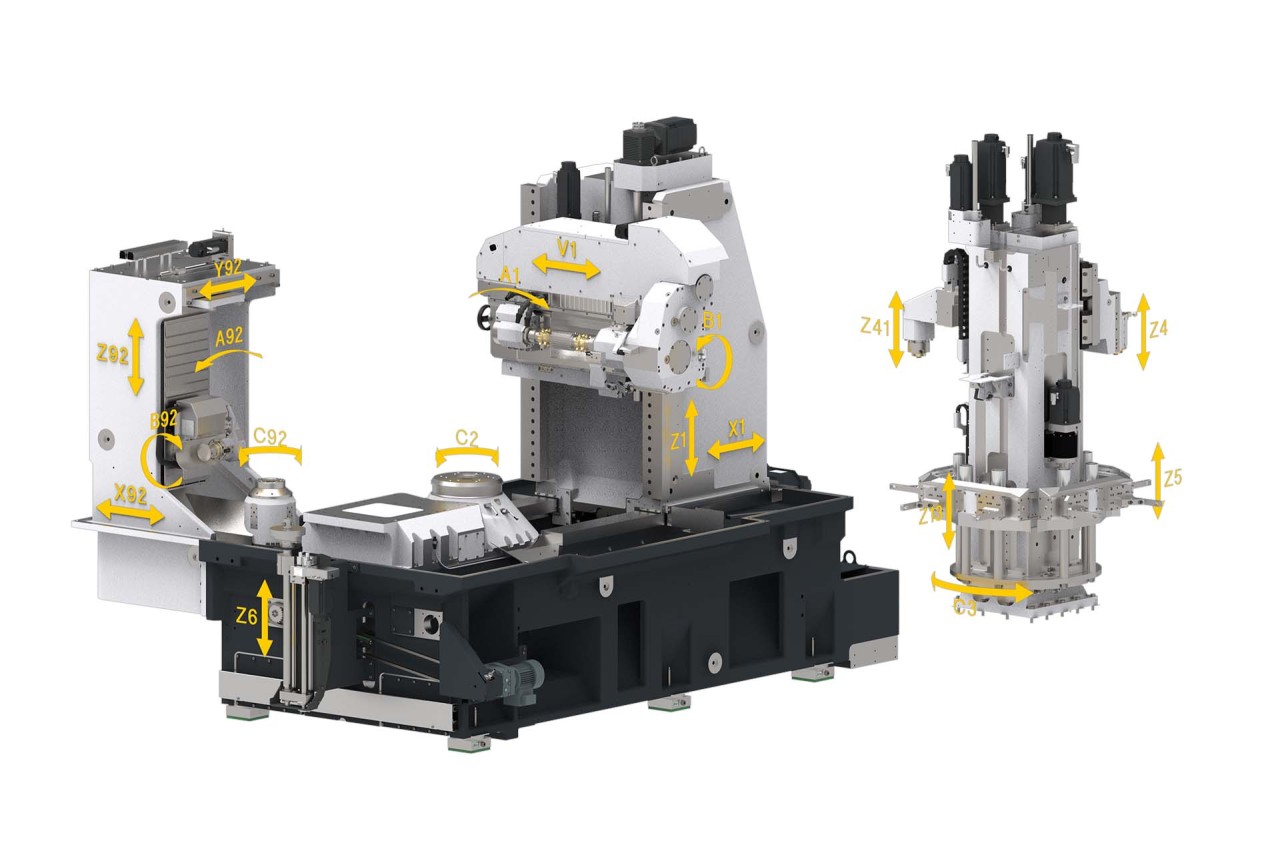

Machine concept

Liebherr gear hobbing machines are optimally customized to the requirements of universal usability. Our high-performance gear hobbing machines are productive and machine in the highest quality.

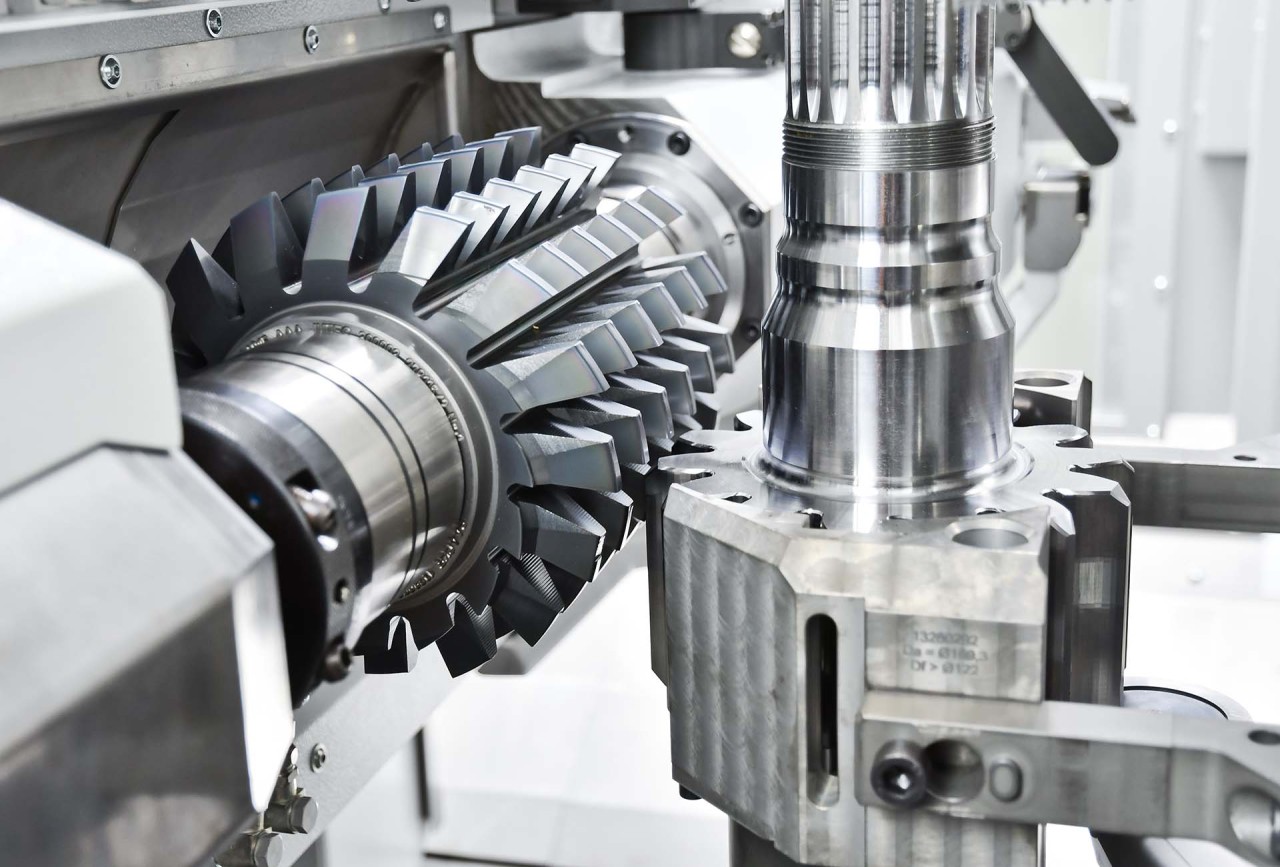

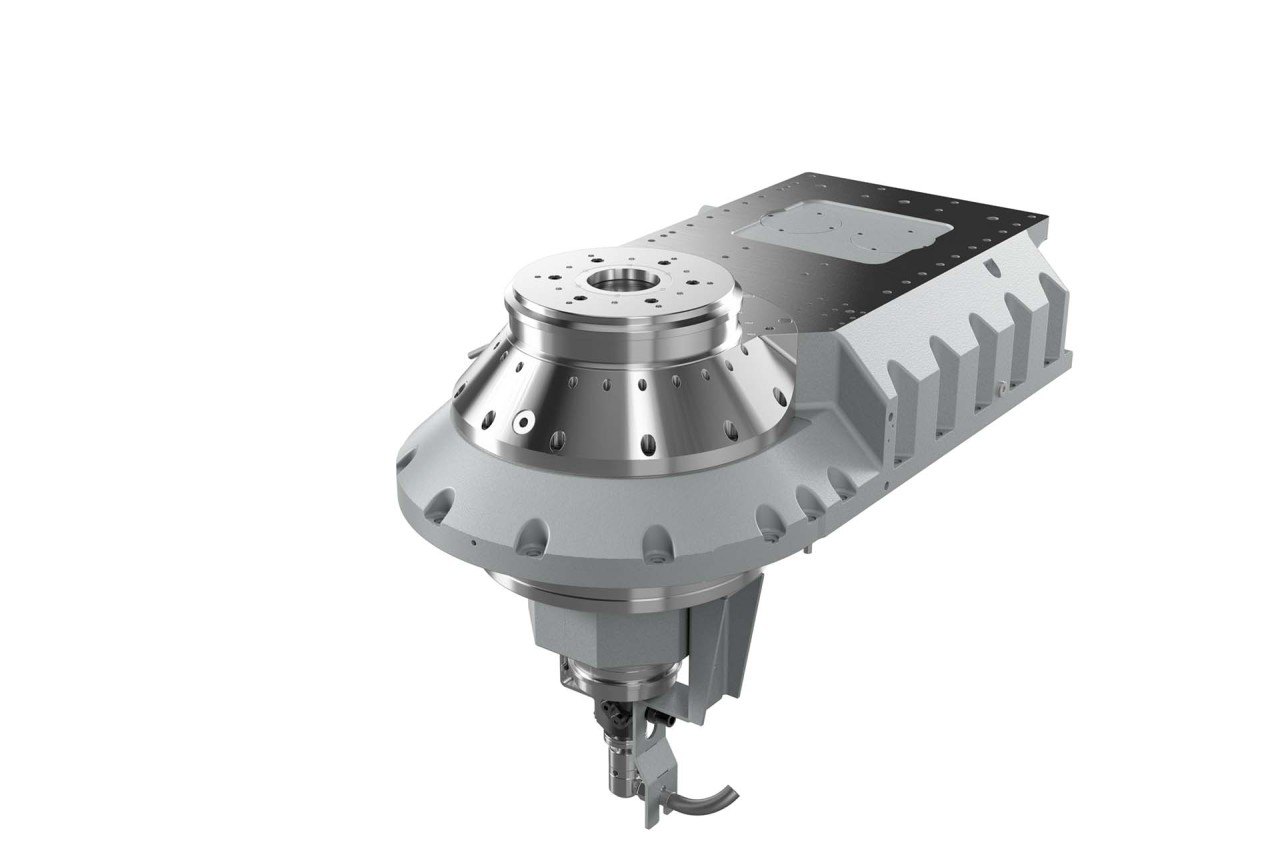

- Gear hobbing head for larger and longer tools delivers greater productivity and flexibility

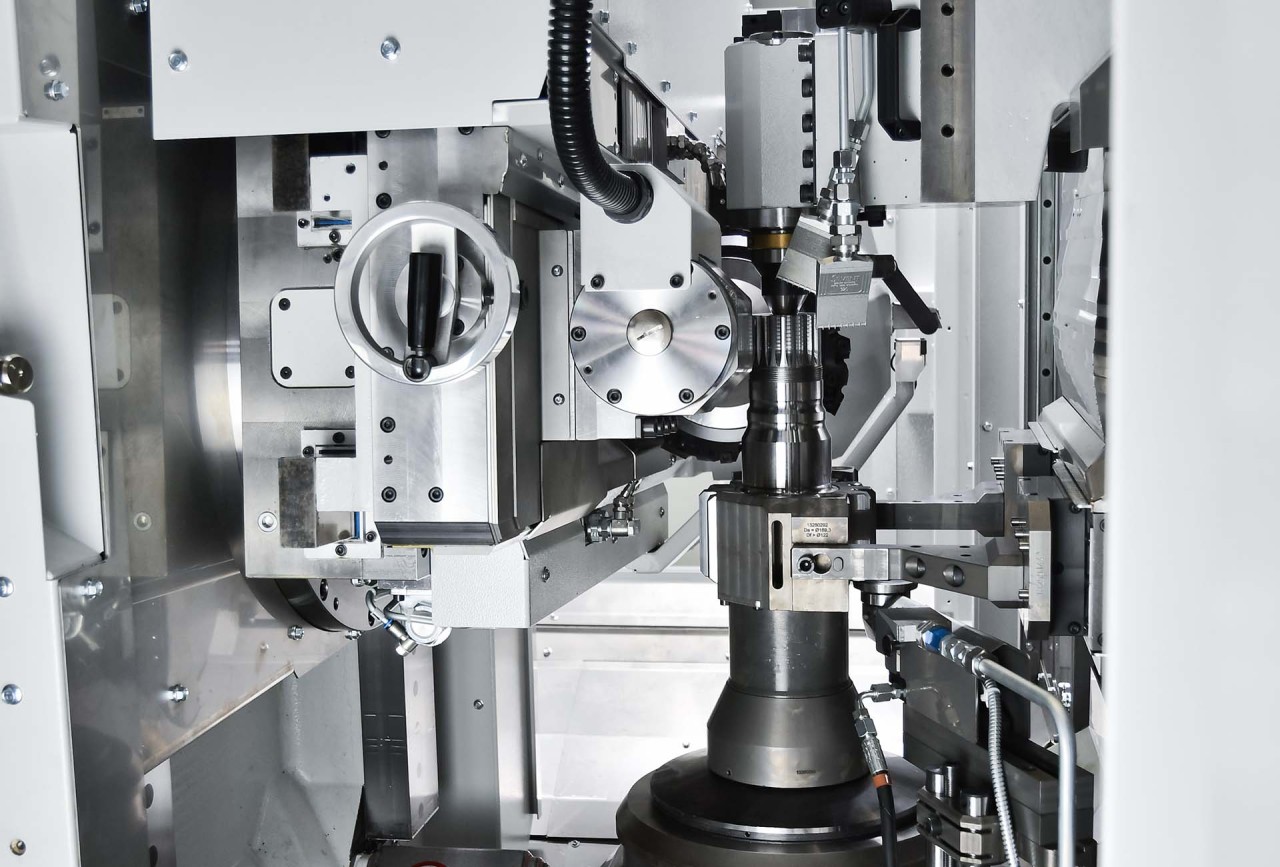

- Chamfering of workpieces of up to 500mm workpiece diameter during the machining process and a module of 7mm with ChamferCut and/or the new FlexChamfer technology

- Maximum flexibility thanks to larger work area

- Counter column with NC technology for maximum ease of setup

- Internal ringloader automation concept for workpieces up to 100kg

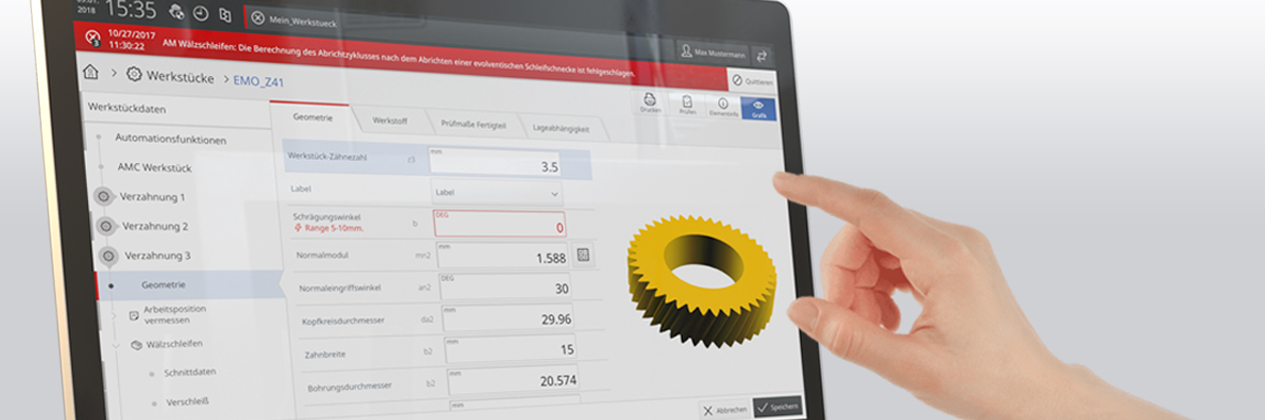

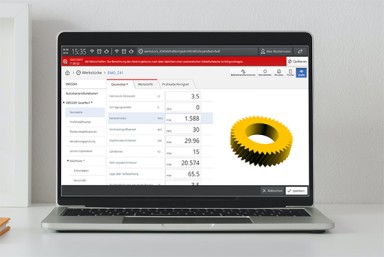

- Operating concept with LHStation & LHMobile and LHGearTec

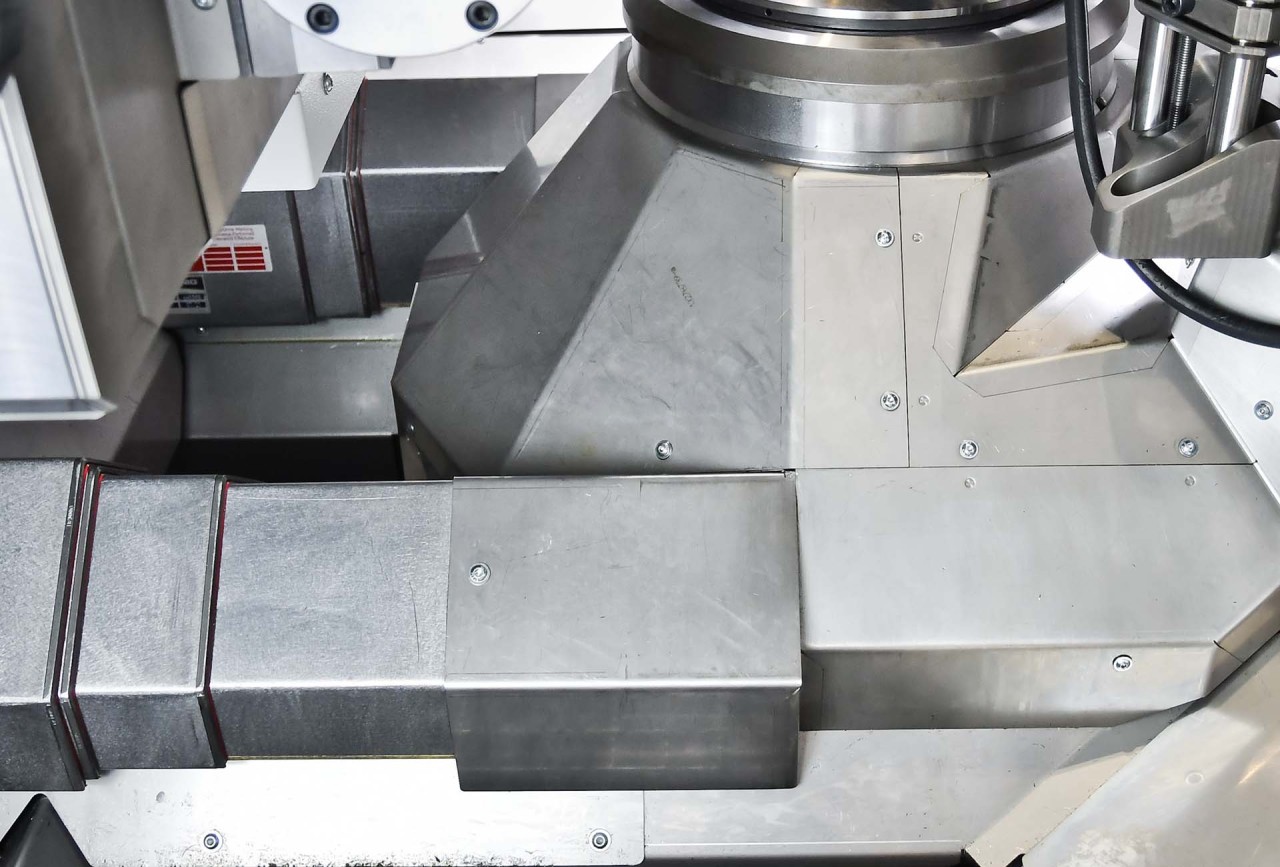

- Improved chip removal thanks to optimized and redesigned machine bed

01/02

01/03

01/02

Maximized operator friendliness

01/03

01/02

Gear cutting and chamfering parallel to machining

01/02

01/05

Technical data

| Module | 3.50 - 16.00 mm |

| Workpiece diameter | 300 - 700 mm |

Variants

| Variants | LC 300 | LC 300 DC | LC 500 | LC 500 DC | LC 300 - 500 / 700 M |

|---|---|---|---|---|---|

| Module (mm) | 12.00 / 16.00 / 9.00 / 3.50 | 12.00 / 16.00 / 9.00 / 3.50 | 12.00 / 16.00 / 9.00 / 3.50 | 12.00 / 16.00 / 9.00 / 3.50 | 16.00 |

| Workpiece diameter (mm) | 300 | 300 | 500 | 500 | 700 |

| Axial travel (mm) | 700 | 700 | 700 | 700 | 700 |

| Shift distance (mm) | 320 | 320 | 320 | 320 | 320 |

| Hob diameter (mm) | 240 | 240 | 240 | 240 | 270 |

| Hob speed (min-1) | 600 / 900 / 1,500 / 3,000 | 600 / 900 / 1,500 / 3,000 | 600 / 900 / 1,500 / 3,000 | 600 / 900 / 1,500 / 3,000 | 600 / 900 |

| Table speed (min-1) | 100 / 170 / 400 | 100 / 170 / 400 | 100 / 170 / 400 | 100 / 170 / 400 | 100 |

| max. module ChamferCut chamfering (mm) | — | 7 | — | 7 | — |

| max. tool speed ChamferCut machining head (mm) | — | 1,200 | — | 1,200 | — |

| max. tool diameter ChamferCut (mm) | — | 130 | — | 130 | — |

| max. table speed (min-1) | — | 1,400 | — | 1,400 | — |

| max. tool clamping length (bore-type cutter) (mm) | 370 / 330 / 350 | 370 / 330 / 350 | 370 / 330 / 350 | 370 / 330 / 350 | 330 |

| max. tool clamping length (shank cutter) (mm) | 460 | 460 | 460 | 460 | 460 |

Gear checking in the machine

A gear check in the machine is optionally available. The quality of components can be checked at regular intervals. You also do not have to wait for results from the measuring room when replacing the tool or fitting a new part.