At Liebherr, the needs of our customers are always our top priority! That's why we have developed tailored, modular systems solutions perfectly suited to your individual application requirements.

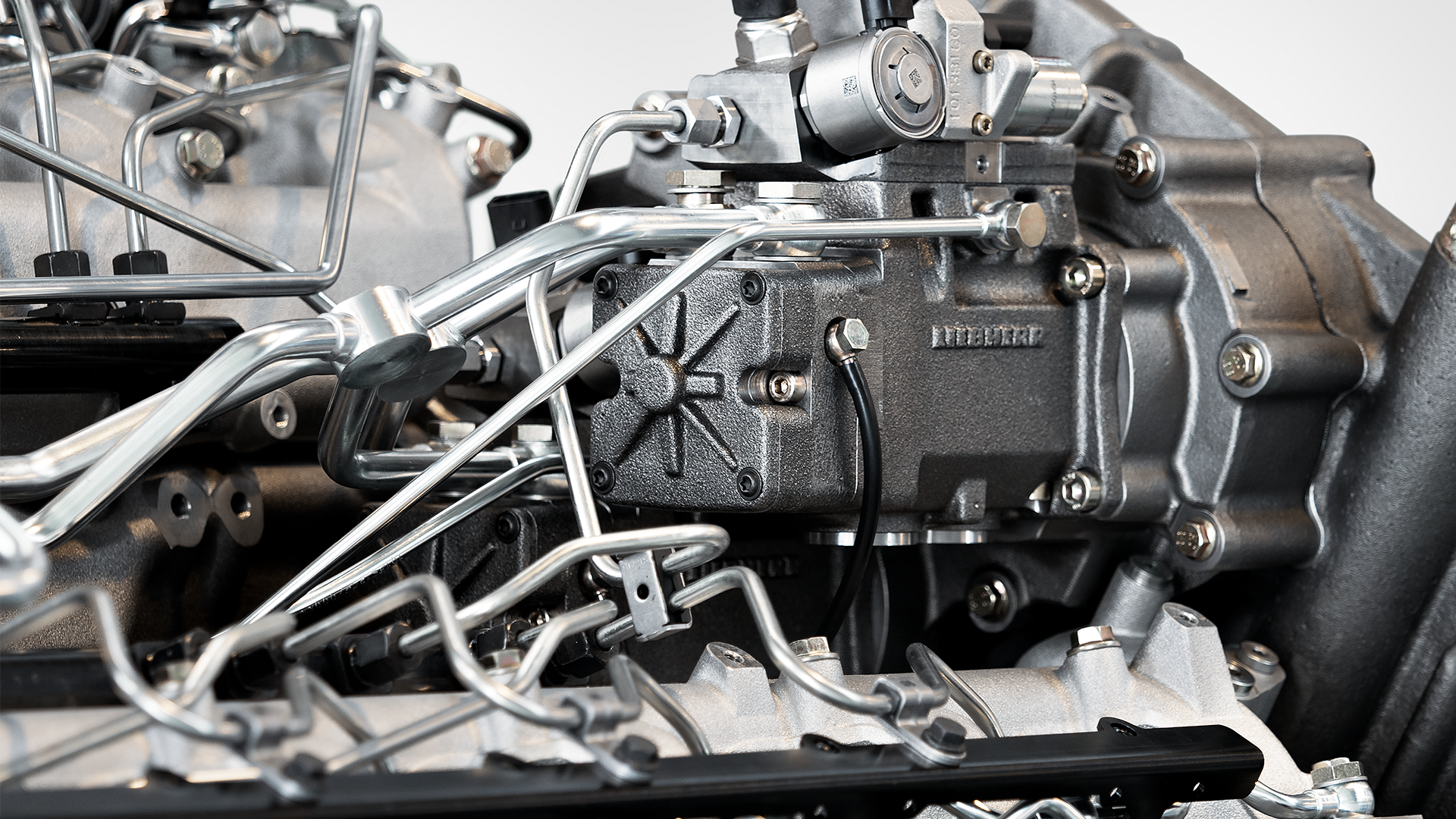

Our common rail systems are characterized by various design options, variable drive flanges, and customized interfaces, offering remarkable flexibility. Depending on requirements, we adjust the injection system to comply with different emission regulations, achieve low fuel consumption, or deliver maximum engine performance, ensuring optimal efficiency and performance.

Discover the versatility and performance of our common rail systems solutions.