Aerospace and transportation systems

Aerospace and transportation systemsLeading in low-GWP HVAC systems

Liebherr leads the industry in low-GWP HVAC systems, with air cycle technology already in operation and advanced HVAC solutions using CO₂ or propane refrigerants are in series production.

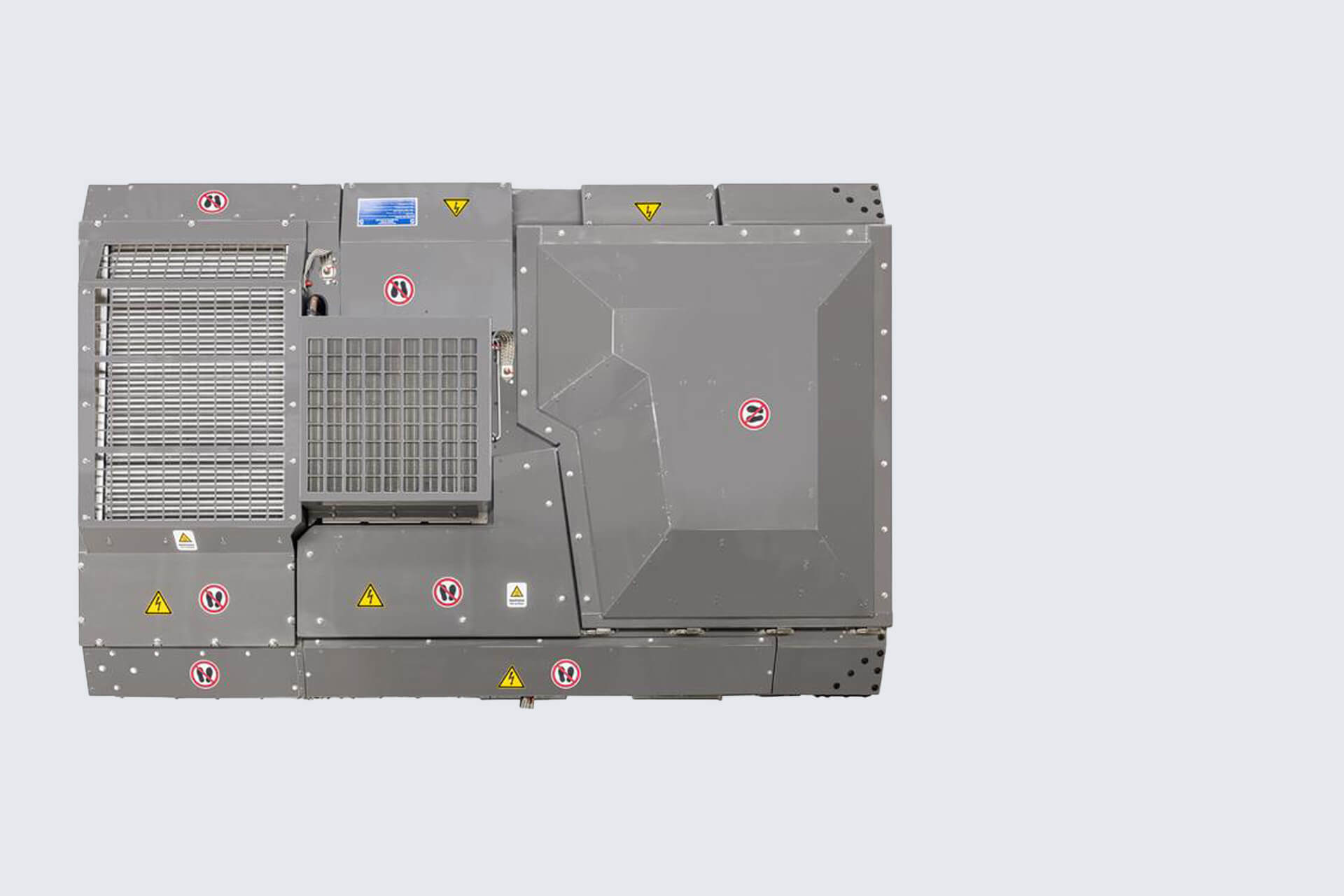

Air cycle HVAC system

Air cycle technology: Climate-friendly cooling for railways

Liebherrs’ air cycle HVAC technology offers a groundbreaking solution for environmentally friendly cooling. Unlike conventional systems that rely on chemical refrigerants, air cycle technology uses only natural ambient air, making it a sustainable choice for heating, ventilation, and air-conditioning in railway vehicles.

How air cycle technology works

The system operates on a simple, innovative process:

- Ambient air intake: Natural air is drawn into the system and passes through a cooling turbine.

- Depressurization: The air is depressurized at the turbine stage, reducing its temperature significantly.

- Heat exchange: The cooled air absorbs heat from the passenger compartment via a heat exchanger.

- Recompression: The air is recompressed to atmospheric pressure, reheating it and enabling the surrounding environment to act as an efficient heat exchanger.

With minimal components—a turbine, compressor, and motor—air cycle systems are compact, easy to maintain, and highly efficient.

Proven performance and environmental benefits

This technology has been successfully adopted by SNCF, the French national railroad company, for its Autorail à Grand Capacité (AGC) trains in the Occitania region. Tested extensively as part of SNCF’s "Eco-Clim" research program from 2015 to 2019, the systems demonstrated exceptional reliability, low energy consumption, and significant environmental advantages.

In collaboration with Deutsche Bahn (DB), air cycle HVAC systems were also tested on ICE 3 trains, showing superior results compared to traditional vapor cycle systems. Supported by Germany’s Federal Environmental Agency, the tests confirmed reduced environmental impact, lower operating costs, and simplified maintenance.

Climate-friendly solutions with CO₂ and propane

The rail industry has made significant progress in adopting more environmentally friendly mobility solutions, and Liebherr is at the forefront of this transformation. By rethinking conventional refrigerants, Liebherr is advancing sustainable HVAC systems using alternative refrigerants like CO₂ and propane.

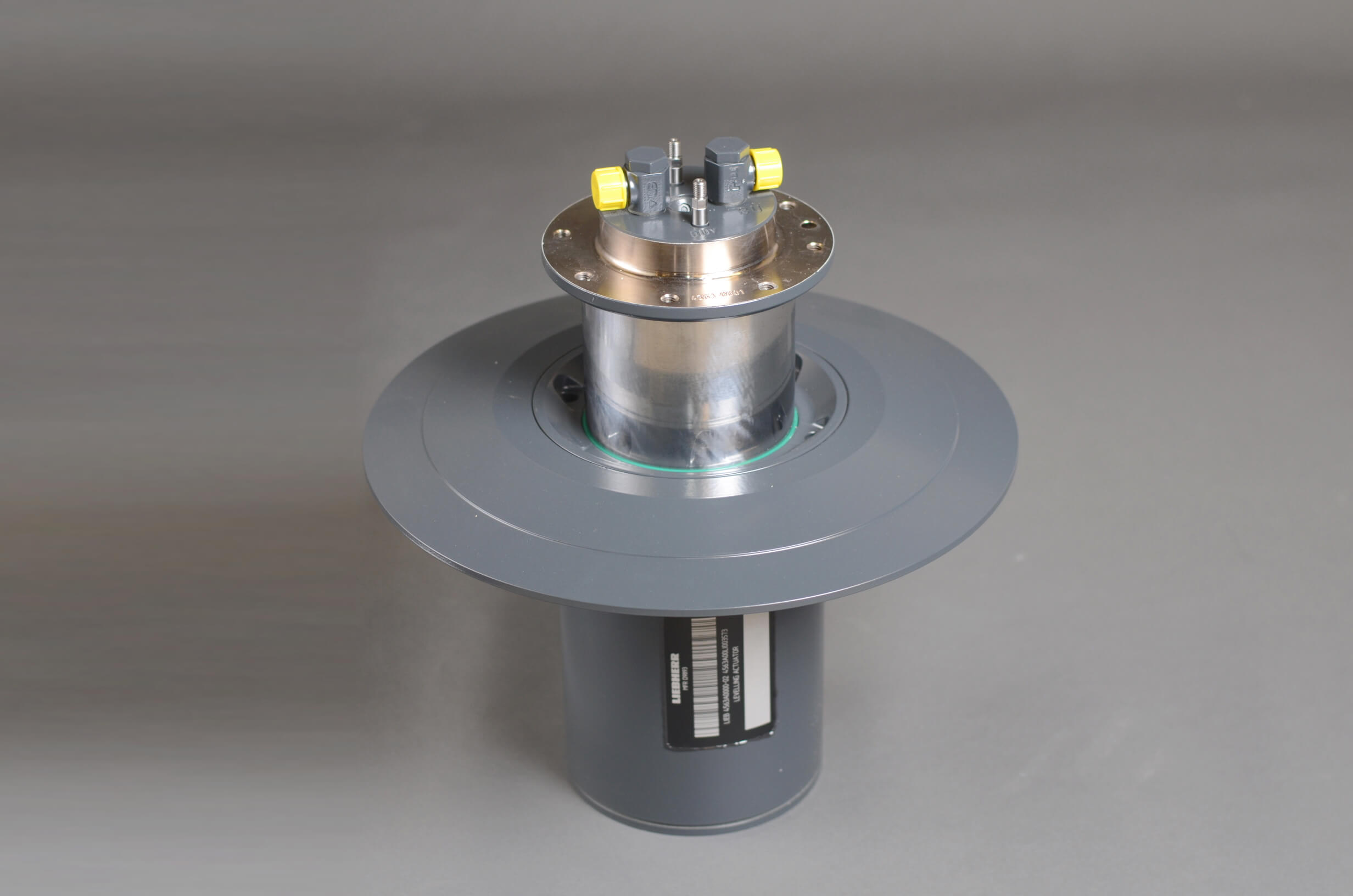

Energy-efficient cooling with CO₂

CO₂, or R744, is a climate-friendly alternative to conventional refrigerants. With a Global Warming Potential (GWP) of just 1, it has a minimal greenhouse effect while being highly energy-efficient in temperate climates, especially when used in heat pump operation. Non-toxic, non-flammable, and cost-effective due to its natural abundance, CO₂ is a promising refrigerant for sustainable rail HVAC systems.

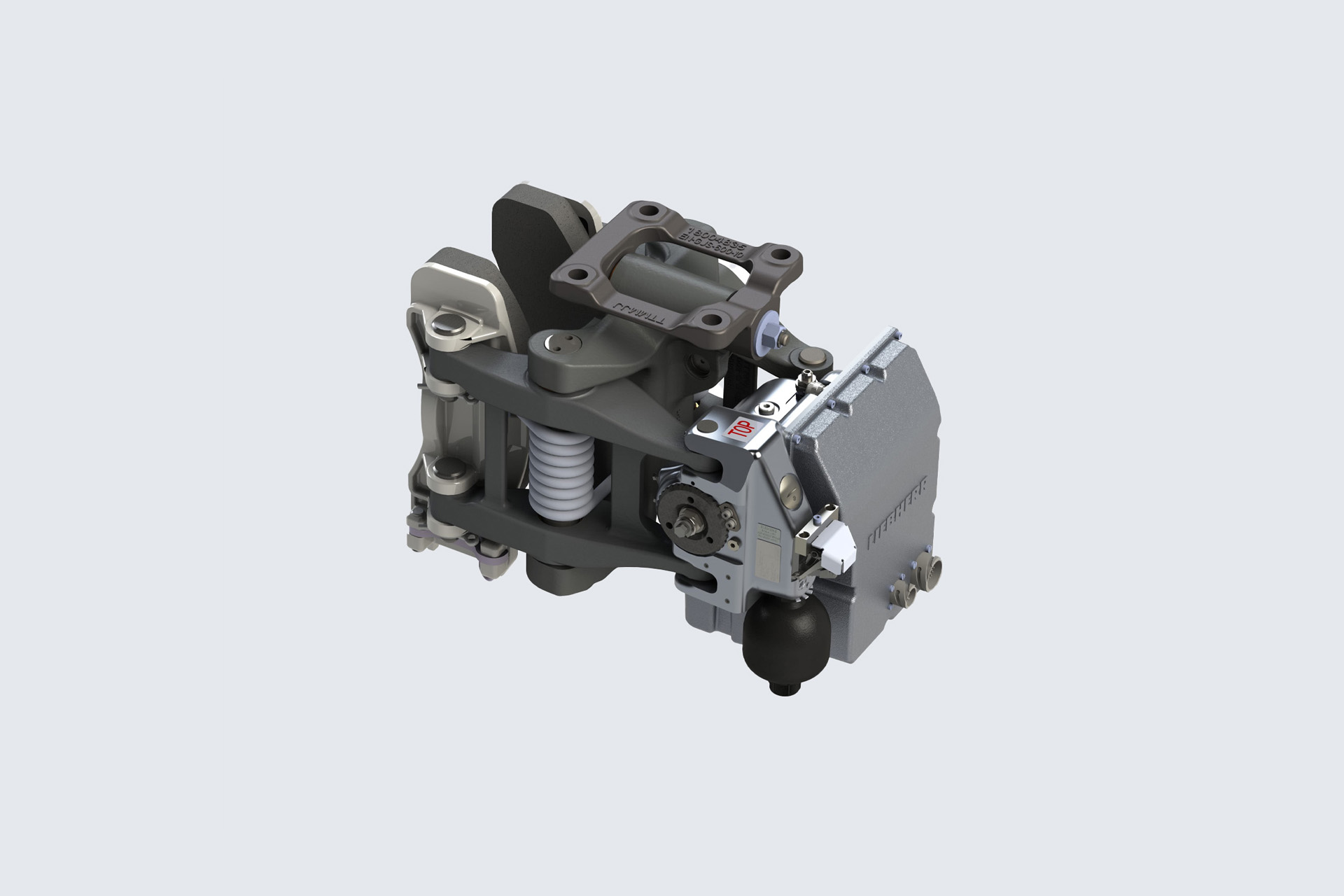

High performance with propane refrigerants

Propane-based HVAC systems, entering series production at Liebherr, mark another milestone in sustainable cooling technology. Known as R290, propane offers a low GWP of 3 while delivering exceptional cooling performance with minimal energy consumption. Its pressure characteristics closely resemble traditional refrigerants, making it a reliable, efficient, and eco-friendly solution. Designed with safety in mind, this system ensures low downtime and operational reliability for rail vehicle operators.