6 minutes - magazine 01 | 2023

Four steps for a better tomorrow

Sustainability and climate change are hot topics at the moment. It is now more important than ever to develop greener drive concepts for vehicles to reduce CO₂ emissions, for example.

So what can we at Liebherr do to ensure that our Liebherr crawler cranes operate more sustainably and with greater green credentials? How can we use less fuel, reduce CO₂ emissions and also save costs? This is what we are working on at Ehingen, cooperating with our own group engine manufacturer in Bulle. Together we are attempting to gradually develop innovations and make improvements to help make our operations both greener and also more economical. This is a particular challenge for our gigantic crawler cranes with lifting capacities of up to 3,000 tonnes. Energy efficiency requires a new approach. Taking all the relevant aspects into account, the concept of the electric drive unit is simply not suitable for us at the current time on our heavy duty crawler cranes. So we have found other ways to reduce fuel consumption by around 20 % and also reduce CO₂ emissions by almost 90 % during crane operations using various measures on crawler cranes. We can now explain in more detail how we have managed it.

1: FFE 30 hydraulic oil

We have had a special hydraulic oil developed for our cranes which has some very special properties – FFE 30 hydraulic oil. It is thinner than conventional hydraulic oil types due to its low viscosity. That also means it develops less resistance in the lines during crane operation, which reduces energy consumption. Nevertheless, it features outstanding lubrication properties. The volume of fuel savings depends on several factors, such as radiator control and temperature. The warmer it is, the less fuel is required. In general, the savings are around 5 % during normal crane operation compared to cranes which use alternative hydraulic oil types.

We have been using this outstanding hydraulic oil as standard in our crawler cranes above 500 tonnes for around ten years. So our special high quality hydraulic oil, with each crane containing around 1,000 to 1,500 litres, helps our customers to reduce fuel consumption – good for the environment and for their wallets.

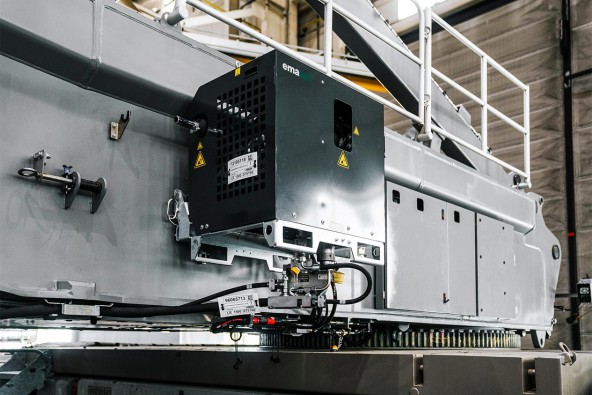

2: APU (Additional Power Unit)

The APU (additional power unit) we have developed is an investment that makes sense as in addition to the air conditioning compressor, this unit can also power the hydraulic oil preheating system without having to start the main crane engine. In addition, the LICCON control system can remain active as the alternator on the additional power unit maintains the crane battery charge. If the ignition for the APU is set to ready, the additional power unit will start automatically, generating 11 kW, as soon as the crane engine’s stop button is pressed. This saves up to 15 % of fuel during normal site operation and also reduces emissions.

Furthermore, the crane engine idles less, which reduces the frequency with which the emission system has to be cleaned. This procedure requires a certain operating temperature and the appropriate fuel to get the engine to that temperature. Furthermore, it means that the crane engine has fewer operating hours, which reduces the frequency of maintenance work and also increases its resale value.

Our ECOmode, which is currently being tested, is another improvement. When ECOmode is active and other conditions are also satisfied, the crane engine is automatically shut down during lengthy interruptions in crane operations, which reduces fuel consumption even further.

All these financial and green benefits make the optional APU a very worthwhile investment. It is available for our LR 1500, LR 1700-1.0, LR 1800-1.0 and LR 11000 cranes. It is actually standard on our larger crawler cranes. We should also point out that it can be retrofitted. If you are interested, contact your Liebherr service partner.

3: HVO ready

Naturally, all our crawler cranes are also HVO ready and fuelled with HVO on delivery. HVO stands for hydrogenated vegetable oil. It is a fuel that works like diesel, but it is not a fossil fuel and is in fact purely vegetable in nature made of food waste, vegetable fat or vegetable waste. HVO is climateneutral both in terms of its manufacture and use as long as it is made exclusively of regenerative energy sources. This must be ensured by HVO manufacturers and suppliers and excluding the use of foodstuffs is particularly important to Liebherr.

During the production process, the vegetable oil is converted into hydrocarbons in a catalytic reaction by adding hydrogen. This can then be used as a fuel to drive an internal combustion engine and reduces CO₂ emissions during crane operation by up to 90 %. The main benefit is that the function of the diesel engine is unchanged – it is simply greener.

HVO can be used flexibly as a pure fuel or mixed with fossil diesel in any ratio for use in conventional internal combustion engines. That means that even older Liebherr engines can be powered on an essentially climate-neutral basis. No modifications are required to the crane itself. In addition to reducing CO₂, soot particle emissions are also reduced, particularly from vehicles without a diesel particulate filter, as are emissions of nitrogen oxides. HVO also delivers good compatibility with all engine components, very good resistance to low temperatures and reduces consumption of AdBlue.

4: Improved load lowering with a closed circuit

Another thing we are working on to reduce fuel consumption is improved load lowering with a closed circuit.

To ensure adequate speeds for lowering loads, to date the process has resulted in the automatic activation of additional braking pumps. The braking energy resulting from this process generates a great deal of heat in the hydraulic oil. Active cooling is therefore required to enable a reasonable temperature level to be maintained, which requires additional fuel consumption. The aim of the improvement is to generate the braking energy by different means without heating the hydraulic oil. Our initial tests have been very promising. We will describe how it works and what effect it has in more detail in a future edition of UpLoad.

This article was published in the UpLoad magazine 01 | 2023.