6 minutes - magazine 01 | 2024

Change diesel particulate filters quickly and and inexpensively

What should I bear in mind when changing the diesel particle filter?

On 1 January 2019, EU Regulation 2016/1628 came into force, which affected all diesel engines installed in our cranes. For this reason, we have been supplying our cranes with Stage V engines to all EU countries and some other countries that also require this since then. In addition to the previous SCR technology (Selective Catalytic Reduction), a closed particle filter system was added, which filters almost all soot particles from the exhaust gas and also helps to protect the environment. Like most filters in technical systems and machines, the diesel particle filter (DPF) must also be replaced at certain intervals. Norbert Maier, Head of the Technical Customer Service department, is responsible for exhaust gas aftertreatment, among other things. He explains what needs to be considered when replacing the DPF.

You are all used to changing oil and air filters regularly – this work is routine when servicing your cranes. But probably very few of you have ever replaced a diesel particle filter on a Liebherr crane, because the vast majority of cranes with emission level 5 have less than 5,000 operating hours on the clock. The DPF only needs to be replaced after this period of operation.

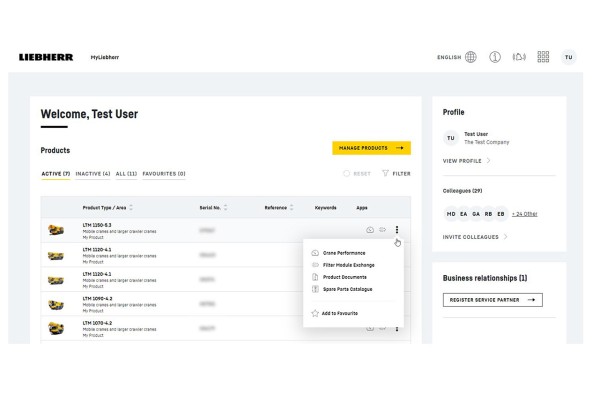

MyLiebherr supports the filter change step by step.

Display on the LICCON screen

When your crane is ready, its LICCON screen will display: “Particle filter DPF Cleaning interval reached, replace DPF filter element.” This message on the screen is the first level of information and warns you that you should now order a particle filter – preferably via the MyLiebherr customer portal. We strongly recommend that you order the replacement filter, whether new or cleaned, from Liebherr, as you will receive a warranty from us.

In the second stage, the main warning, the LICCON screen will display: “Particle filter DPF Cleaning interval reached, replace DPF filter element – reduction!” Now the change must be carried out promptly, a power reduction is already triggered. In contrast to the replacement of other filters, we have decided to display the request to replace the DPF via LICCON instructions. It is essential that the filter is changed correctly, as the crane control system must be informed of the change and the load status of the filter, i.e. the amount of soot and ash, must be reset to “zero” at the same time. You will need a reset code from Liebherr. This is a matter of component protection – the filter could be destroyed if this is carried out incorrectly.

Norbert Maier

Support from MyLiebherr workflow

To support our customers, we have created a workflow via the MyLiebherr customer portal that accompanies the filter change step by step. It works for all LICCON2 cranes and allows you to change the DPF completely yourself. This saves costs and increases flexibility in your planning. Only on very few models with LICCON1 control do you need your Liebherr service partner to reset the load status of the DPF via the engine control unit.

Now to the workflow: A “Filter Module Exchange” button is available for your cranes registered in MyLiebherr from LICCON2 control and Stage V. If you activate this, you will receive a brief explanation of the “Generate reset code” function on the screen. In the next step, the required data is requested: Machine serial number, engine serial number, serial number of the newly installed filter module and the date on which the reset was carried out. The fields are already pre-assigned with the data available in MyLiebherr, including the filter serial number if it was purchased via Liebherr for a specific piece of equipment.

The reset code can be generated four weeks into the future from the current date. The reset code is generatedmfor entry on the selected date and instructions are provided for download. In addition, you will receive all information by e-mail. Important: The reset via the LICCON control system must take place on the exact day planned. We recommend carrying out the complete replacement process, including resetting, on the same day: Filter change, MyLiebherr workflow and reset via the LICCON control system.

We are pleased to be able to make you a new digital offer free of charge with the workflow described. Of course, our Customer Service and our worldwide service partners will be happy to change the diesel particle filter for you.

The Brazilian market – young, aspiring and full of potential

You can change the diesel particle filter completely by yourself. This saves costs and you remain flexible in your planning.

“While we initially only accepted used cranes in exchange for a new crane, we now also buy back our used cranes without this condition,” says Rechtsteiner. “At the same time, we are continuing to drive forward our used crane business internationally.” Brazil is still a relatively young but promising market – particularly with regard to the development of renewable energies and the associated construction projects, such as the erection of wind farms.This is where large cranes are used.

The Group is represented by two production companies at the Guaratinguetá location in the state of São Paulo. “As part of Liebherr Brasil, which was founded in 1974, we offer the complete programme for the mobile crane division here: technical customer service, a spare parts warehouse on site, 16 service engineers stationed at various locations throughout the country, as well as a workshop where any repairs can be carried out,” reports Felix Mussotter from Sales South America.

In recent years, business with used cranes has also picked up considerably in South America’s largest country. “For around two years, we have been supplying more used cranes to Brazil, particularly large cranes with five axles or more, as well as crawler cranes. This development is mainly due to the lengthy delivery times for new cranes, which can be around twelve months since the coronavirus pandemic,” reports Mussotter. And Rene Porto, Division Manager for Mobile and Crawler Cranes at Liebherr Brasil, adds: “On the one hand, the wind power sector is fuelling demand for used cranes. On the other hand, there are numerous projects in the mining and oil & gas sectors that give rise to corresponding demand. Young used cranes that are up to five years old are in high demand.”

This article was published in the UpLoad magazine 01 | 2024.