R 9800 G6

The best choice for large scale mining operation

The R 9800 was designed to thrive in the toughest mining conditions. The combination of its modular design, 80,000-hour service life, and extended component lifetimes helps to maximise this machine’s time in the pit. Plus, the R 9800 can move more material with less! This efficient mining solution has the best payload capacity in its class and, thanks to Liebherr’s proprietary engine management system, Liebherr Power Efficiency – Engine Control, it can save up to 120,000 litres of fuel per year.

Operating weight with backhoe attachment - 800.00 t

800.00 t

Operating weight with face shovel attachment - 810.00 t

810.00 t

Engine rating at 1800 rpm - 2,984 kW

2,984 kW

Bucket capacity at 1.8 t/m³ - 47.50 m³

47.50 m³

Shovel capacity at 1.8 t/m³ - 42.00 m³

42.00 m³

R 9800 highlights:

Built to last over 80,000 operational hours

12% more payload capacity

120,000 litres saved per year

The Liebherr R 9800 is probably about 20 to 25 % in front of what we budgeted the machine to be digging at. The cycle times are just out of this world compared to what we’ve seen at Bengalla in the past. It’s really, really impressed.

Technical data

| Engine model | 2x Cummins QSK 60 |

| Engine rating at 1800 rpm | 2,984 kW |

| Emissions (USA/EPA) | Tier 2 / US EPA Tier 4f / EU Stage V |

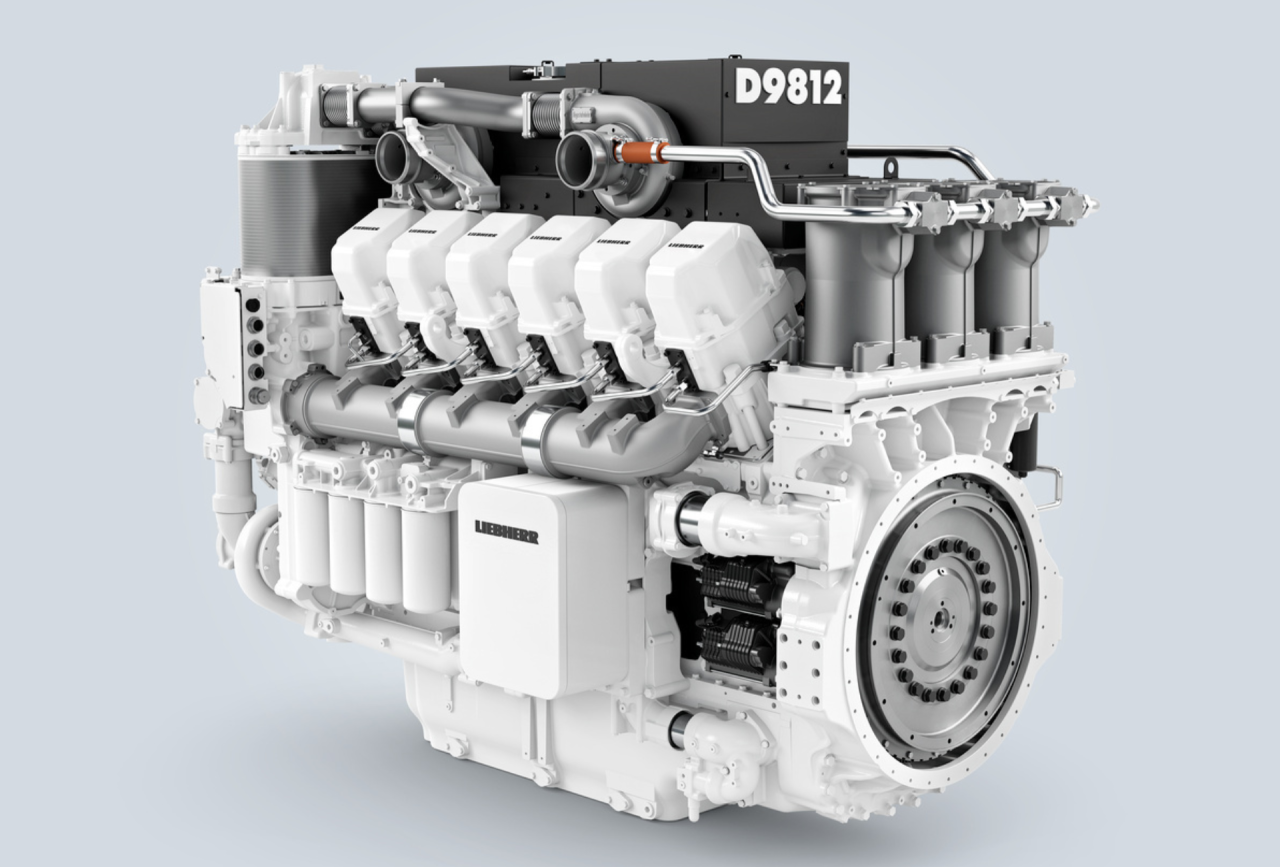

| Engine model (option A) | 2x Liebherr D9812 |

| Engine rating at 1800 rpm (option 2) | 3,000 kW |

Downloads

Videos

Product video R 9800

Machine gallery

Minimise your carbon impact

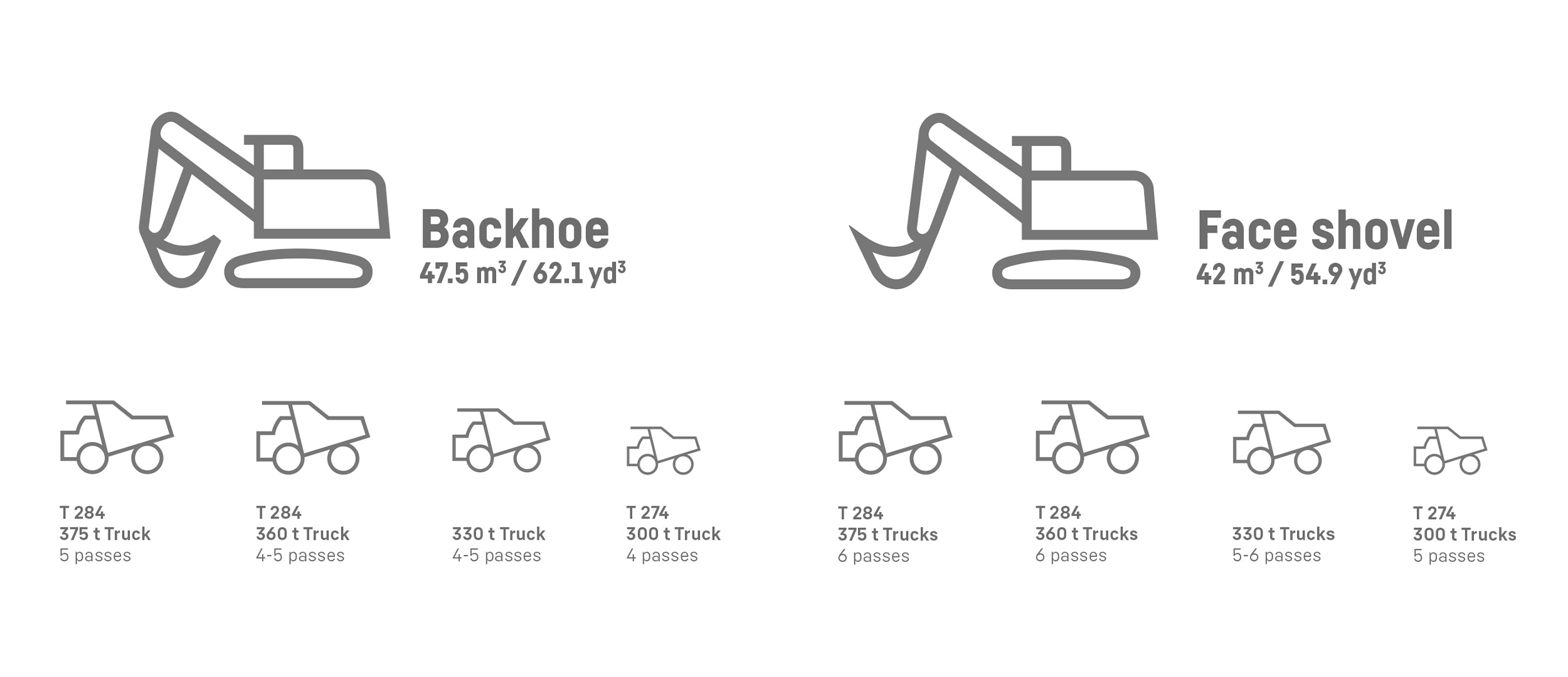

Excavator truck match*

*Site-specific factors like loose material density, bucket size, fill factors, truck body size and payload capacity will influence pass match. Contact your local Liebherr affiliate or sales partner for analysis of your site.

The perfect Liebherr pairing

Discover the perfect pairing for the R 9800 excavator with our innovative truck match solution. Explore the seamless synergy between our advanced excavator technology and high-performance mining trucks, setting a new standard for excellence in the industry.