7 minutes reading time

High voltage

Turning ideas into solutions is one of the classic virtues of engineering. Liebherr is forging ahead with the process and product innovations of the new e-mobility age. And knowledge sharing and interdisciplinary collaboration are key drivers of success.

When engineers go deep

Divers are experts when it comes to fathoming out unfamiliar environments. Working with trusted technology is part of their daily routine, and they know the value of being able to fully rely on their diving partners. So, why are the right technology and teamwork so important? According to sport diving enthusiast Jürgen Appel, ‘Your diving goggles allow you to see your surroundings much more clearly underwater. This let me find out things about the ocean that I would not have seen otherwise.’ The enthusiastic sport diver is a machine builder by trade. For a good year now, he has been bringing together various future- and development projects in the product segments in specially created expert groups in Liebherr's Corporate Technology department.

New drive concepts are a major focus of his work, along with e-mobility and the challenges and opportunities that it creates for the industry. ‘Many product segments are focusing on innovation in many different ways. Sometimes, there are overlaps in the kinds of topics and questions they’re dealing with. We compile these areas within our expert groups, where we regularly meet to exchange knowledge’, explains Appel. ‘This way, everyone benefits equally.’

Automation: The future of vehicle manufacturing

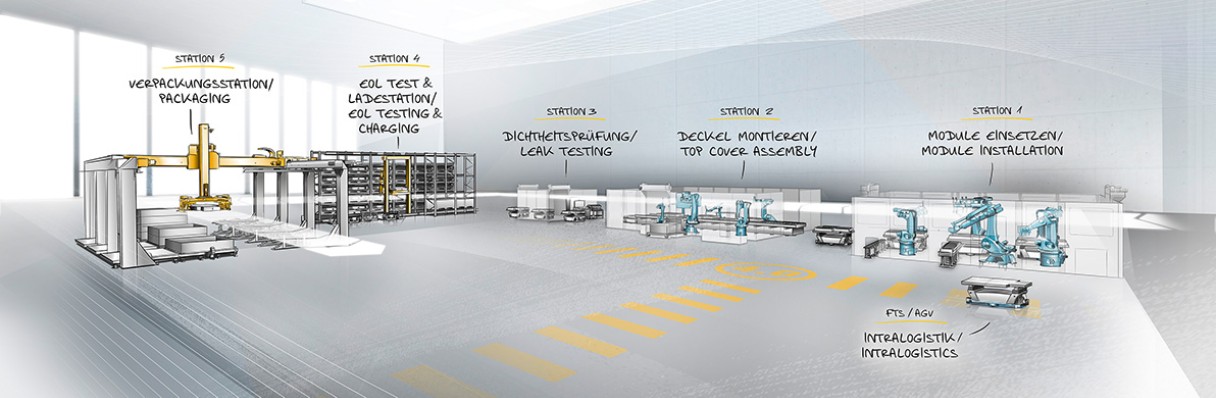

A good example is battery pack manufacturing for electric vehicles, a process which is becoming increasingly automated. Viktor Bayrhof from Market Sales & Product Management in Liebherr’s Gear Technology and Automation Systems product segment is working in Kempten (Germany) to develop new production techniques for the vehicle manufacturing industry of tomorrow.

1

Viktor, how is the shift towards e-mobility changing the way vehicles are manufactured?

Viktor Bayrhof: With electric vehicles, there’s no combustion engine or transmission to install. That means we’re dealing with an entirely new vehicle architecture. It’s uncharted territory for a lot of our customers. Just to give one example, there is a fundamental difference in how battery packs are assembled, compared with conventional drive technologies, like engine blocks, crankshafts or gearboxes. That’s because this single piece of equipment involves many different manufacturing and technological processes. And that has an impact on the entire production. A pre-assembled pack for passenger vehicles can weigh up to 800 kilograms. But that’s a walk in the park for Liebherr handling systems.

Viktor Bayrhof, Market Sales & Product Management Automation Systems at Liebherr-Verzahntechnik GmbH

2

Within the automotive industry, assembly lines are usually built to last for long production cycles. How much room does that leave for new developments?

We’re living in a time of change. The era of the combustion engine is coming to an end. The European Union has laid out a plan to make Europe climate neutral by 2050.This means CO2 emissions will be strictly regulated. Since the EU's climate targets cannot be met with combustion engines or hybrid vehicles alone, the EU is specifically promoting electric vehicles. Some automakers want to phase out combustion engines as early as 2025, and there are studies that show that by 2040, fuel-burning vehicles will be a thing of the past within the EU. The corona virus pandemic has also clearly sped up this trend. At the same time, there have been major investments in battery research, which have led to countless innovations that make batteries more powerful, longer-lasting and more cost effective. For us, this means speeding up the development of our automation solutions and keeping our projects lean enough to be able to respond quickly to these changes in the market.

3

So, how has Liebherr started the ball rolling?

It started with a development project that we did in collaboration with scientists from KIT Campus Transfer, an offshoot of the Karlsruhe Institute for Technology, and PEM Motion, which was brought to life by the production technology and electromobility components department at RWTH Aachen University. We all got together and looked at ways in which our knowledge and expertise might help to actively shape the way electric vehicles are produced. It was an incredibly intense learning process. In the end, we designed a modular system for automating the assembly of battery packs for the automotive industry. This is a system that we can fully configure to meet each customer’s individual requirements. It’s fully scalable, so we can design anything from a semi-automated system for building small batches to a fully automated line for large-scale serial production. And it’s built for safety. There are hazardous, flammable substances involved in building battery packs. There’s also a risk of electric shock. Our system takes all these risks into account.

4

What does this system do that older systems can’t do?

We were looking for a made-for-purpose solution that can handle the tools and get the job done. We opted for a modular design that can be scaled as needed. We decided to use linear portals, which save space and make handling the heavy battery packs much easier. These can be combined with any industrial robots the customer wants to use to perform more complex handling and production tasks.

5

Can you tell us how the modular approach works?

The customer decides for themselves how they want to assemble a battery pack. We supply the know-how and the system expertise to get the system and its processes up and running. And safety is always our top priority. Fire safety, in particular, is crucial for production processes, because if a pack catches fire, there’s no way of putting it out. So, we put all the right safeguards in place to make sure that doesn’t happen. Even with all these precautions, there is a chance that the battery cells might spontaneously combust. This is what we call thermal runaway. If that happens, there has to be an emergency procedure in place, so we can isolate any pack that’s on fire or about to combust, and transfer it from the production system to a secure burnout chamber.

6

You spoke about ‘uncharted territory’ in production. How are you making this more accessible for customers?

This summer, we’ll launch the new test system at our Tech-Center. This is a high-tech facility, where we can replicate the most technically complex part of the production chain for assembling battery packs. It will give our customers a real-life view of what we can offer them as a full-service contractor to automate their production lines. Before the customer orders a system to use in large-scale serial production, they can come to our Tech-Center and we’ll help them do a test run of core processes, like automated screw driving or dosing, using their own prototype. For the electrical contacts of the battery modules, we offer an innovative automated solution for plug-in high-voltage module connectors as an alternative to screw-on bus bars. Our Tech-Center brings the whole process to life for our customers. There will be exhibits, prototypes, endurance runs and stress tests, just like at a trade fair, except that here we can also directly train employees and customers on how to use the systems. It’s going to be really exciting.

From experience to expertise

What makes interdisciplinary innovation and product development so exciting? For Jürgen Appel, it’s all about the open exchange of experiences. ‘We are constantly sharing ideas. At the same time, each product segment remains true to its own unique approach. This is crucial to our success as a whole.’ There’s never a lack of topics or innovative ideas to discuss. ‘It’s also important to narrow our focus within our working groups to prioritise areas where it’s especially useful to exchange knowledge,’ explains Appel. Thanks to their diverse backgrounds, each team member has something unique to contribute. For example, there’s the experience of preparing the LR 1250.1 unplugged, the world’s first battery-powered crawler crane, for its first deployment in Norway. Or years of pioneering work in the field of network-connected material handling technologies or electric mining trucks. As always, the solutions to technical challenges like these lie in the details. And that’s the kind of knowledge that each member brings to the table.

Cool cables

For example, in the efficient charging of battery-powered vehicles. This is a speciality of Dirk Junghans, Managing Director Sales, Marketing & Customer Service at Liebherr-Transportation Systems GmbH & Co KG. The 58-year-old electrical engineer is focusing on new cooling systems for charging stations for electric vehicles on the way to smarter and greener mobility.

Dirk Junghans, Head of Sales, Marketing and Customer Support at Liebherr Transportation Systems GmbH & Co KG

1

Mr Junghans, e-mobility, batteries and cooling systems... how do all these fit together?

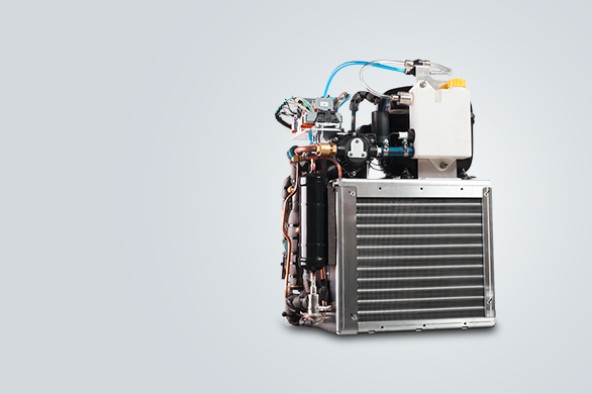

High-voltage lithium-ion batteries, like the ones increasingly used in buses and trains today, are not only relatively expensive, they are also labour-intensive. They must be operated permanently within a narrowly defined temperature range to ensure the desired longevity and thus the return on investment: cooled in summer and heated in winter. That’s where our thermal conditioning units, or TCUs, come into play. A cooling circuit keeps the battery’s temperature precisely within the specified range, accurate to the degree.

2

How does the experience and expertise of Liebherr Transportation Systems contribute to developing battery-cooling technology?

We’ve been working on developing high-performance climate-control systems for railway vehicles for over three decades. We’ve built up quite a lot of expertise over the years when it comes to heating, ventilating and cooling passenger train cars and driver’s cabins. It seemed only natural to apply this know-how to temperature management for high-voltage batteries. In other words, we can draw on a wide range of experience to help in our work on e-mobility.

3

Driving range is still a critical point for e-mobility. When the battery is empty, you want to be able to recharge as quickly as possible. But it’s not as quick and easy as refuelling a combustion car, is it?

Charging time is always a hard sell when it comes to getting customers to accept new technologies. The strength of the current that you use to charge the battery determines how long you have to wait at the charging station. So, for fast charging, we’re working with high current-strengths. The standard right now is 350 amp. Just to give you an idea, a single-family house is usually supplied by a 40-amp connection. We’re seeing an upward trend for charging stations. Fast-charging stations with 500 or even 690 amp currents are already in development.

4

Sounds like we’re on the right path then.

Any time you transport current through a cable, you’ll always have heat build-up. Basically, the higher the current, the hotter things get. You can counteract this by increasing the diameter of the charging cable, but that also makes the cable heavier. Eventually, as the capacity of the charging stations increased, cables became so heavy that many customers simply couldn’t handle them any longer. The solution is to actively cool the cable and the plug during charging. Especially when you’re dealing with stronger currents. Soon, we may even hit the 1,000 amp mark.

The active cooling units, also known as "thermal conditioning units" (TCU), were developed specifically for e-mobility charging stations

5

How is Liebherr leading the way in improving the way electric vehicles are charged?

We’re building our thermal condition units, or TCUs, into fast-charging stations for electric cars. They keep the temperature of the cable and the plug at the optimal level and effectively discharge the excess heat. We were the first in the industry to use a high-efficiency cooling medium in our TCUs. We lower it to a predefined temperature and then pump it at high speed through the hermetically sealed cooling circuit that is wound around the current-conducting elements of the cable and the plug. This is what we call active cooling. That means that the TCU works similarly to a climate-control system, except it isn’t conditioning air, it’s conditioning the cooling medium we use. Another important factor is the Liebherr Group's structure and its global service network, which is set up to provide service and maintenance for complex systems like these at any time.

6

So, now that we have a safe, high-power charging system, are we about to see the breakthrough of e-mobility?

Our efficient cooling systems can definitely play an important part in that. If we want to reach the ambitious climate targets though, the power used at the charging stations also has to come from renewable energy sources. We also know that battery-powered vehicles alone will not be enough to solve the climate crisis. There are still lots of construction machines, for example, that require so much power that there isn’t a purely battery-based solution yet. So, there will definitely also be a need in the future for other technologies, like fuel cells and hydrogen drive systems. And we’re closely following those developments too.

Back to the basics: The engineer’s virtues

When Jürgen Appel thinks about the future, he’s anything but afraid. ‘If Liebherr only knew what Liebherr knows....’ to quote a phrase commonly heard within the company. ‘We’re finding a new way to structure all the knowledge we’ve accumulated. It’s a vast amount of knowledge, but it’s quite spread out. There is so much potential for the future when we pool our knowledge and exchange our ideas,’ says the mechanical engineer. ‘We live in times when classic engineering virtues are once again becoming essential. Topics like digitalisation are extremely important, but they only tell part of the story. We need to pool our knowledge in a structured way, so we can keep pushing product and technology development forward and ultimately build something. That’s what it’s all about. At the end of the day, we want to come up with a product or technology that really moves progress forward, for our customers and for society. It’s an incredible undertaking to be a part of that, for all of us.’