Kelly visualization for drilling rigs

Correct locking of the Kelly bar: The Kelly bar must be continuously locked and unlocked during Kelly drilling. For this purpose, the so-called drive keys have to be positioned in the interlocking recesses of the Kelly bar. The operator has to approach the locking points cautiously as these are not visible. This task is both demanding and time-consuming.

It’s not so easy

The performance of the machine is negatively affected if the Kelly bar isn’t properly locked during lowering or extracting. Further, the guides and interlocking recesses on the Kelly bar become worn and it can also lead to damage on the rotary drive or carrier machine.

Graphic support

Kelly visualization helps the operator by displaying the position of the locking recesses on the control monitor. This means they can be approached more safely and quickly and correctly locked.

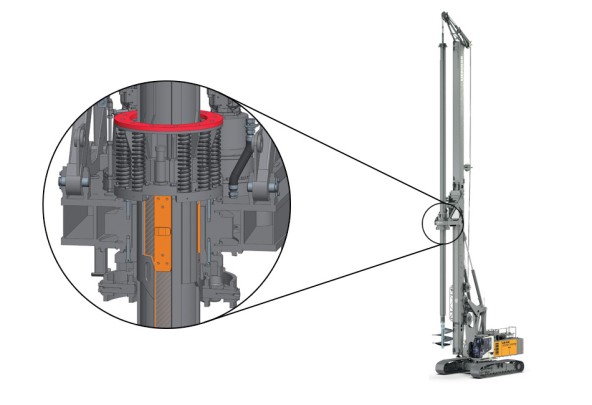

Unlocked

The drive key is not exactly level with the locking recess. The operator may not turn the rotary drive.

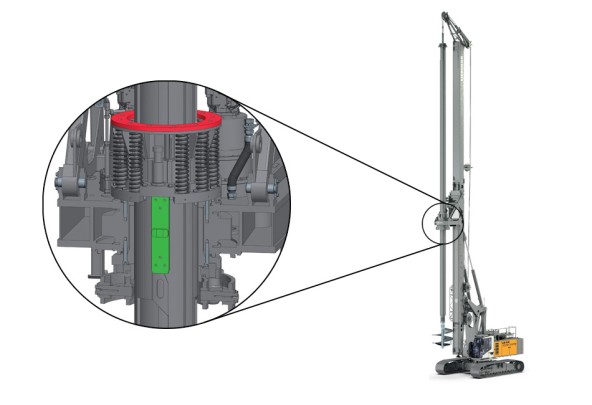

Locked

Colour indications inform when the bar can be locked. This applies to all individual sections of the Kelly bar.