_w1920.jpg)

3 minutes | magazine 02/2018

My Tip: Cut off your hoist rope.

Johannes Hirschle explains this short tip with a massive effect. He has been using his expertise for Liebherr in Ehingen since 1977. As a customer service fitter, he has been travelling around the world for you and your cranes for almost 30 years.

Johannes Hirschle, customer service fitter

When you are working with large cranes in a wind farm, your hoist rope is constantly stressed. The high number of hoists, involving heavy loads alternating with zero loads, subject the rope to extreme strain. For applications of this type it makes sense to shorten the hoist rope from time to time.

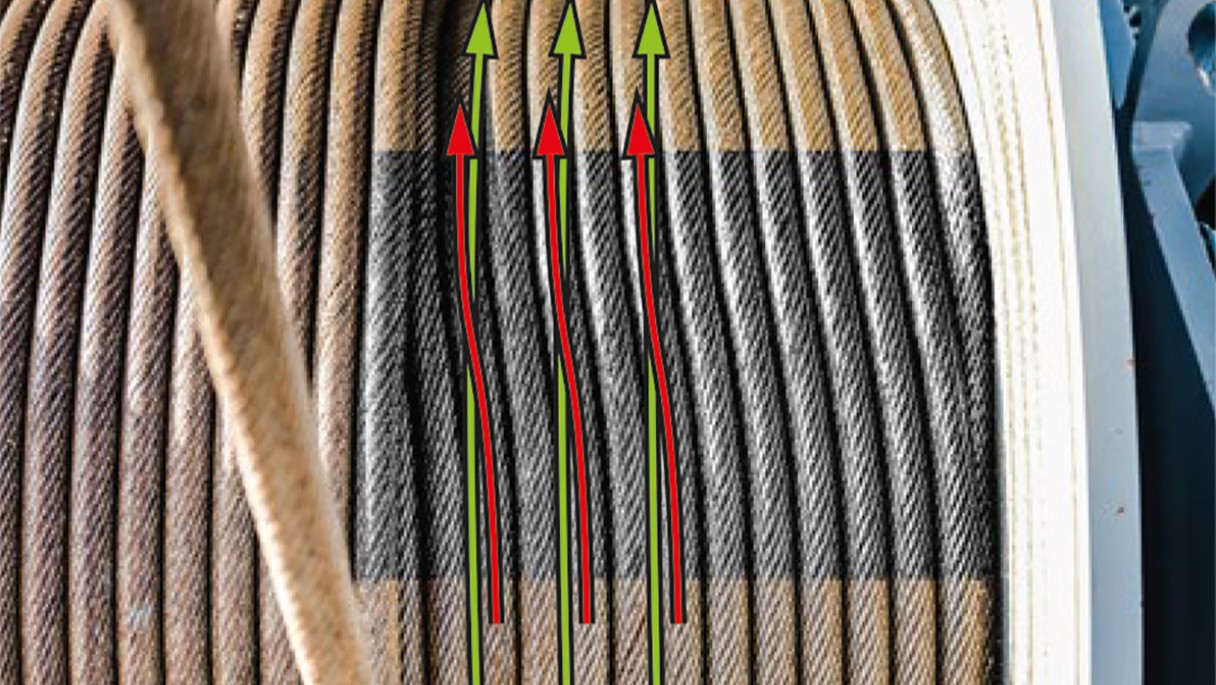

It is wound onto the winch with highly developed multi-layer rope coils in a precise geometry involving lotsof layers. The rope windings on the upper layer cross over those on the lower layer. And this is precisely where the rope suffers most stress.

Proper rope care can save lots of money!

My tip is designed to ensure that this does not result in damage requiring the rope to be replaced. Shorten the hoist rope before it requires replacement. This relocates the stressed crossing areas to the less stressed parallel area of the winch. This results in asignificant extension to the rope service life.

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).Instructions for this process are available in our short training film or from your Liebherr partner. The following is important in this respect:

• The hoist rope must be secured before it is released

• It must be shortened by 20 times the rope diameter

• It must be welded or soldered expertly

• The rope binding must not come loose whilst the rope is being cut.

The Liebherr Customer service team will then reset the safety cut off. After that the hoist rope must be recoiled under load.

The rope windings on the upper layer across the windings on the lower layer. There is unavoidable friction wear in the rising sections.

This article was published in the UpLoad magazine 02 | 2018.