Made with Liebherr

Monuments, stadiums, outstanding buildings and places for lots of people to gather – Liebherr cranes are needed everywhere and they are in action all over the world. That means we can say with pride – Made with Liebherr.

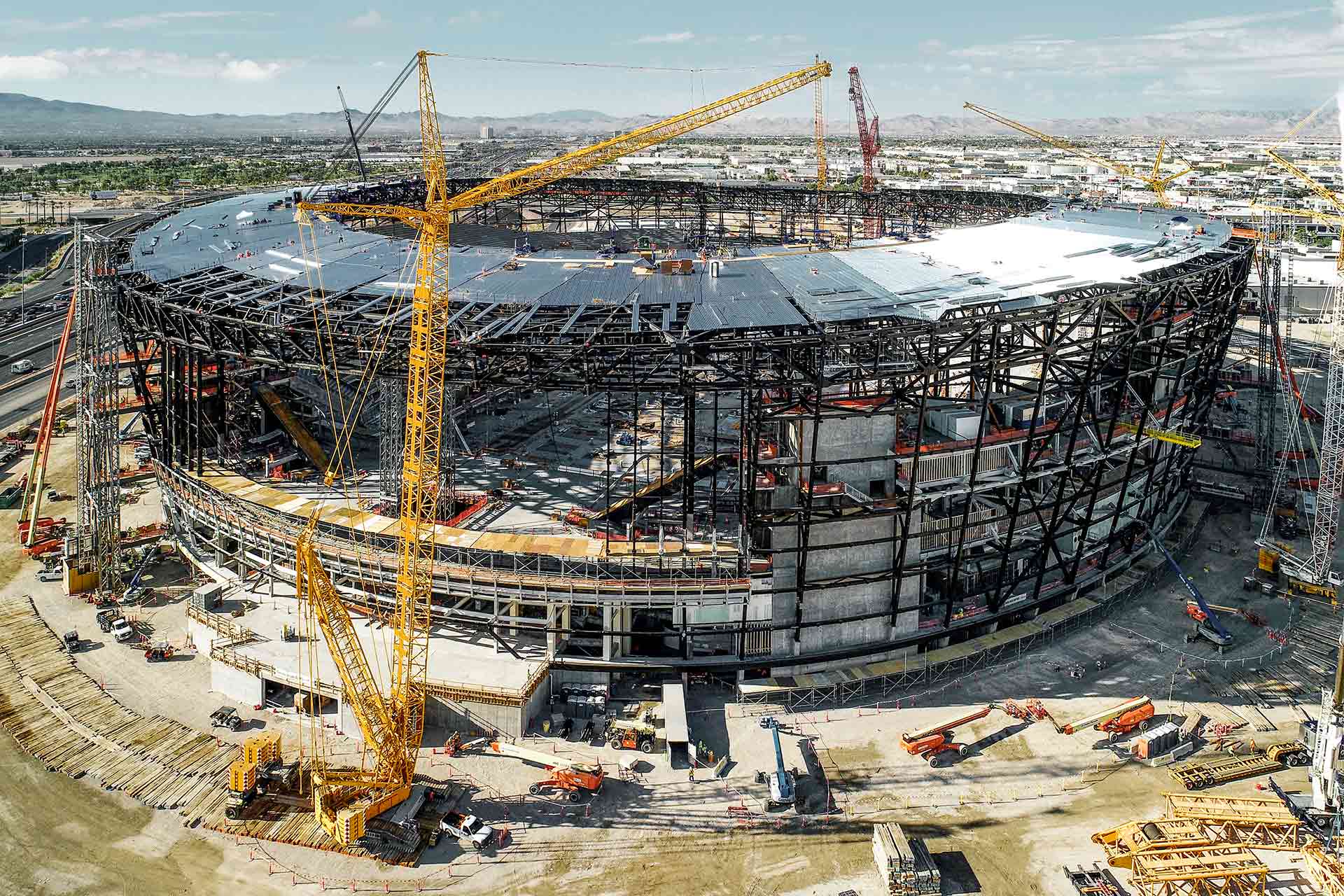

Building a new stadium in Las Vegas

Work started on the construction of the new Allegiant Stadium for American football and soccer in Las Vegas on a greenfield site in 2017. After three years, it was finished on 31 July 2020. The arena, which holds 65,000 spectators, cost around 1.9 billion US dollars. At times there were more than ten crawler cranes working on the site, including an LR 1500 crane and several LR 1300 SX models. The newly purchased LR 1500, owned by crane rental company Dielco based in Las Vegas, was in action both for erecting the structural steelwork and also for hoisting the shell elements into position. As a result of its large radii and lots of different positions which the crane had to take up during the construction work, it was set up with a ballast wagon. The first official match in the new stadium was held on 21 September 2020.

The Brussels landmark

Erected in 1958 for the World Expo in Brussels, the Atomium, which represents an iron molecule magnified billions of times, was supposed to have been removed again six months later. However, the people of Brussels could not bring themselves to remove their world famous landmark. And so, in 2005, the Atomium was due for a full refurbishment – with an LR 1350/1 doing the honours.

Beauty therapy for the Brussels Atomium

The quirky formation reaches 102 metres into the Brussels sky. In 2005, a Liebherr crane temporarily towered over it by around 40 metres. Belgian crane and heavy haulage specialist Sarens helped refurbish the city’s landmark using an LR 1350/1-LN crawler crane. The complete outer skin of the 18 metre thick globes was replaced with corrosion-resistant steel plates. A lattice boom crane had to be used to complete the work on the topmost of the nine spheres, which also houses a restaurant, as a result of its altitude and the fact that a radius of up to 76 metres was required.

The team spent around eight weeks up in the air simply to place a new skin around the topmost sphere. The LR 1350/1-LN remained in a single position whilst it completed all the hoisting work. With its 66 metre main boom and 78 metre luffing jib, the Liebherr crane was able to carry out work all over the high altitude site.

Eltz Castle

In the valley of the River Elz, a tributary of the River Moselle in the German state of Rhineland-Palatinate, there is a very special mediaeval treasure perched on a rock 70 metres in the air. Eltz Castle has seen many wars come and go and has remained undamaged. It has been owned and maintained by a single family every since it was built in the 12th century. Its architecture is unlike any other structure and is an original work dating back eight hundred years. Liebherr cranes played a major role in the extensive refurbishment work carried out at the landmark between 2009 and 2012.

Refurbishment work at Eltz Castle

Eltz Castle is the archetypal German mediaeval castle and once featured on a 500 mark note. The structure has never been attacked and is therefore fully preserved. What is more, the noble Eltz family, which has owned the castle for more than 800 years, has carried out restoration work at regular intervals. The shaky structure was secured, damaged roofs and half-timbered structures repaired and the rotten internal equipment replaced in extensive refurbishment work carried out between 2009 and 2012. In April 2010, an LTM 1350-6.1 mobile crane erected a 280 EC-H tower crane to assist with the restoration work. The main boom weighed 12.5 tonnes and had to be installed using a radius of 45 metres. The special challenge for the job was that the mobile crane was 29 metres below the level of the tower crane.

Made with Liebherr

Mobile and crawler cranes from Liebherr are in action every day on behalf of horse fans, history buffs, efficiency experts, churchgoers, art lovers, train drivers, crane fans and many more. A very wide range of structures has been and continues to be created all over the world – made with Liebherr.

Berlin Cathedral’s crowning glory

For two and a half years, the people of Berlin looked at their city’s landmark with deep regret as it was missing a very important component. A replacement for the cathedral’s cupola cross, which crowns the building, was under construction and being gold-plated from December 2006 to August 2008. Originally, the plan was to restore this jewel. However, the rust damage proved to be so bad that it was irreparable, so a new cupola cross had to be made. Metal construction company Breidenbach based in Peiting was engaged to design the new cupola cross. A Berlin-based specialist then undertook the production of the new piece, consisting of a cross, sphere and crown, with 1.5 kilograms of gold leaf. After a brief prayer, an LTM 1500-8.1 from Berlin crane contractor BTB hoisted the 15 metre high, 12.5 tonne cupola cross to a dizzying height onto the cathedral’s cupola. Since then, the landmark has been shining with a whole new level of brilliance.

Pegasus & Dragon

The largest bronze horse statue in the world, in the form of Pegasus and Dragon, was created in 2015 at Gulfstream Park in Florida. A Liebherr LTM 1400-7.1 mobile crane operated by American contractor Allegiance Crane worked on the project. The order for the statue was awarded to art foundry Strassacker in Süssen. Strassacker engaged Stark, an engineering agency based in Ludwigsburg and Miami and comprising a team which specialises in special support structures, to develop the technical design, plan the erection work and produce the wide-ranging complex engineering solutions required for the statue.

Eye catcher with 58 tonnes

The 400 tonne crane was equipped with Y-guying and full ballast for this job. The crane took care of its own erection procedure. The left wing of the Pegasus was the heaviest single component, weighing in at a massive 58 tonnes. The Liebherr crane had to hoist this component at a radius of 22.3 metres. The new statue is now a magnet for visitors and an eye-catching symbol for a new equestrian sports park featuring various entertainment and leisure facilities.

With combined forces

An LR 1750 and an LR 11350 from Scottish crane contractor Weldex hoisted a 560 tonne bridge arch in 2017 onto the substructure of the Ordsall Chord Bridge, a new railway bridge in the English city of Manchester. Prior to this, the crawler cranes had to move the bridge arch in stages around 30 metres to the river bank.

Great care and precision

After several hours of hard work, the job was then finished – the bridge arch was hoisted onto the bottom section of the bridge with great care and precision and, more importantly, with no complications. At 89 metres in length, the structure is the first railway bridge in Great Britain with an asymmetrical network arch and also the second-longest of its type anywhere in the world. A unique structure!