Creating optimal environmental comfort for passengers and crew

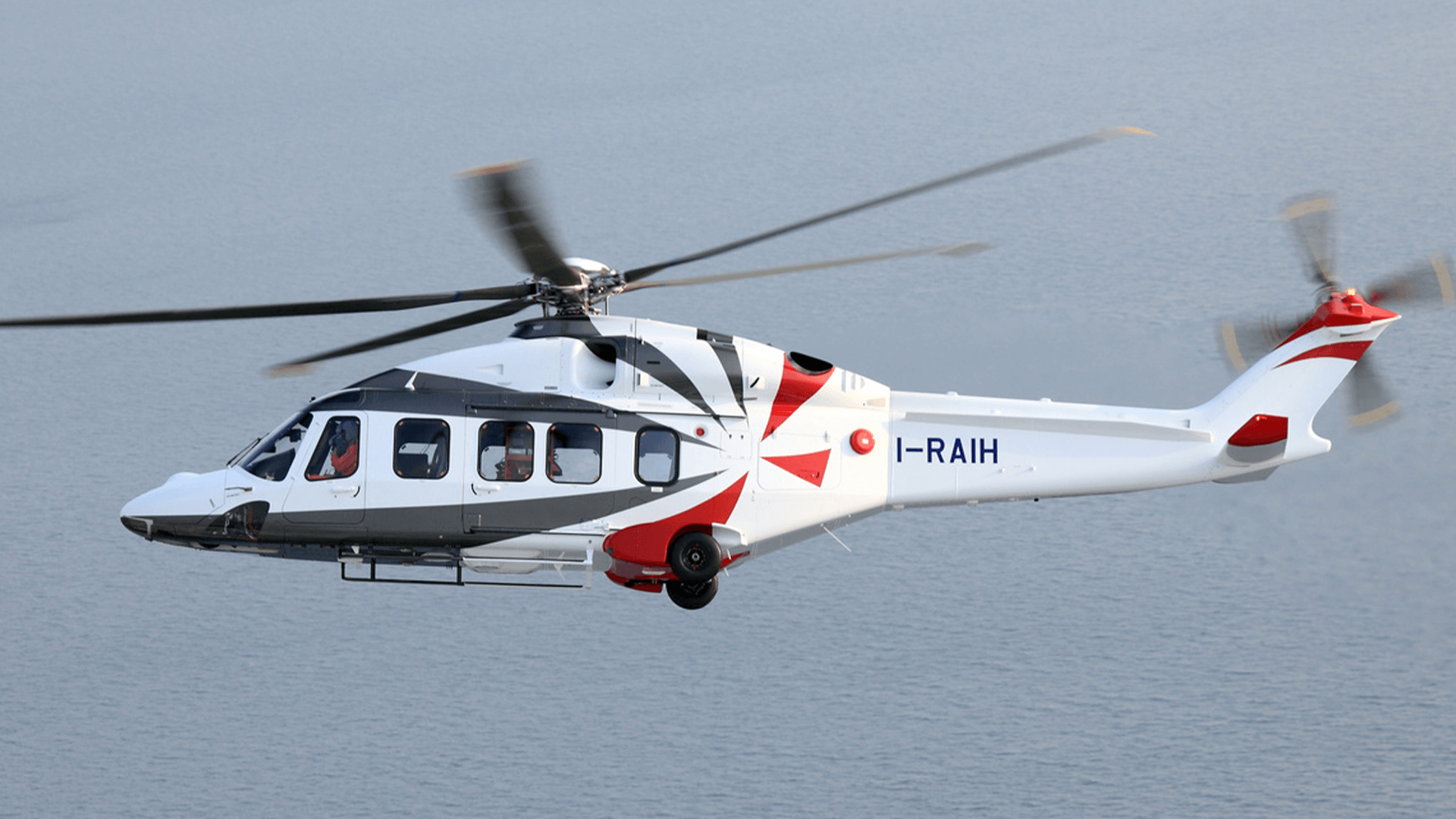

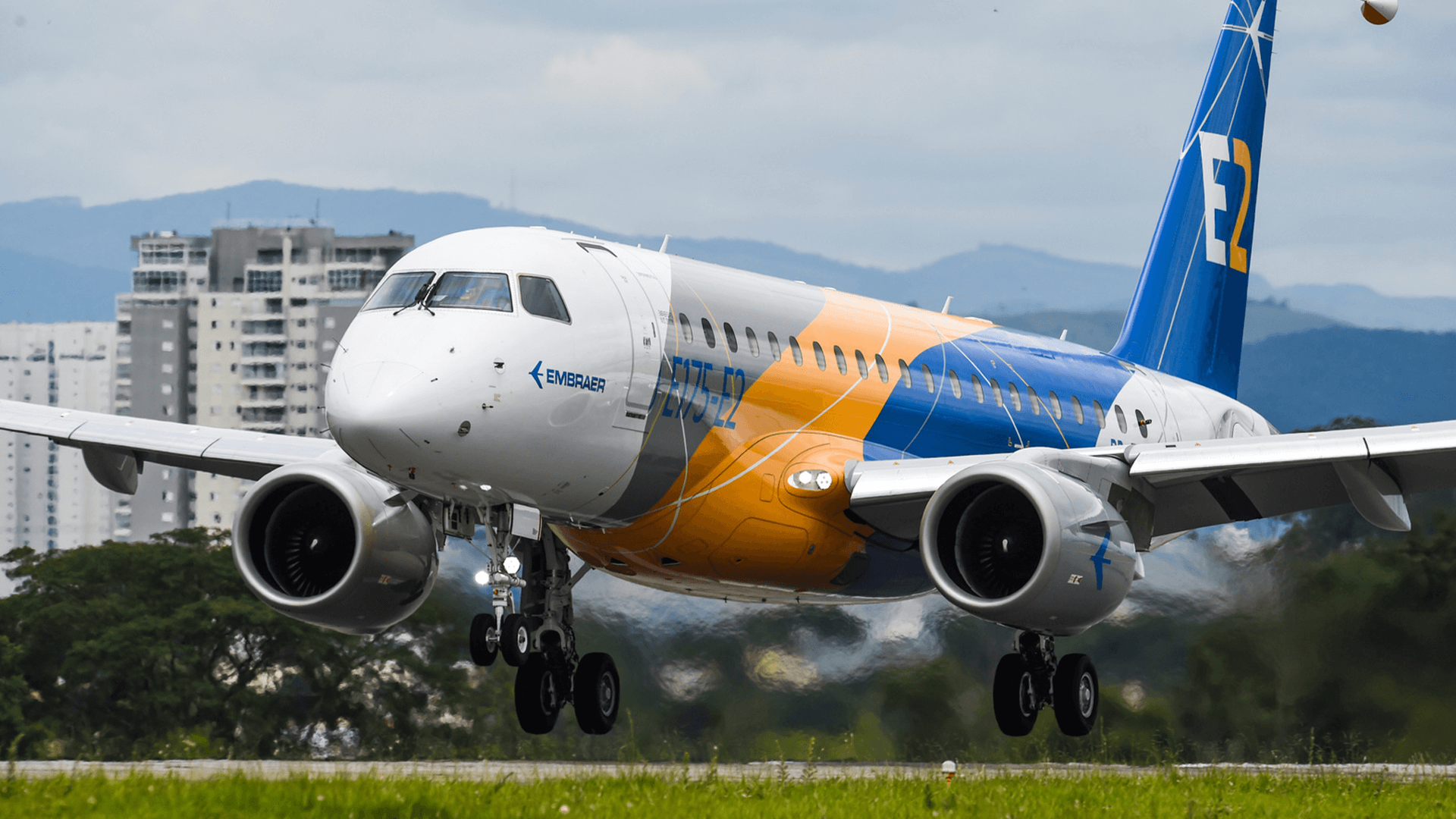

Liebherr designs and delivers integrated air management systems, including bleed and air conditioning systems, cabin pressurization, air distribution, ice protection, and supplemental cooling. Supporting all types of aircraft platforms, Liebherr ensures comfort, reliability, and efficiency throughout the system’s lifecycle.

Benefits of partnering with Liebherr

Integrated systems

Solutions for all markets

Lifecycle support

Environmental control and cabin comfort

Liebherr provides advanced environmental control and cabin comfort solutions, including air-conditioning, humidification, ventilation, anti-icing and pressurization.

Designed for comfort, safety, and efficiency, these systems are tailored to meet the rigorous demands of aerospace applications.

- Air-conditioning

- Ventilation and heating

- Humidification

- Engine bleed air systems

- Ice protection

- Cabin pressure control system

- Fuel tank inerting air supply

- Testing capabilities

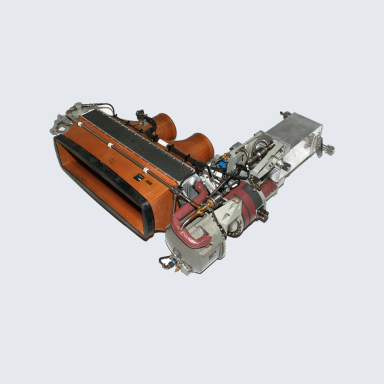

Air-conditioning systems ensure a safe and comfortable cabin environment for passengers and crew while ventilating and cooling avionics and electronics. These systems process high-pressure, high-temperature air, typically sourced from the aircraft engines via the bleed air system. At the core are air-conditioning packs featuring air cycle machines with air bearing technology for enhanced reliability.

These machines are usually pneumatically driven but can also be electrically or mechanically powered. Additional components include heat exchangers, re-heaters, condensers, water extractors, valves, sensors, and controllers. The cooled air is distributed and circulated throughout the cabin via the cabin distribution system, maintaining a consistent and comfortable environment.

Air-conditioning systems ensure a safe and comfortable cabin environment for passengers and crew while ventilating and cooling avionics and electronics. These systems process high-pressure, high-temperature air, typically sourced from the aircraft engines via the bleed air system. At the core are air-conditioning packs featuring air cycle machines with air bearing technology for enhanced reliability.

These machines are usually pneumatically driven but can also be electrically or mechanically powered. Additional components include heat exchangers, re-heaters, condensers, water extractors, valves, sensors, and controllers. The cooled air is distributed and circulated throughout the cabin via the cabin distribution system, maintaining a consistent and comfortable environment.