Intelligent construction site

Comprehensive planning – efficient implementation – spot-on analysis

Digitalization offers the construction industry diverse opportunities for increased performance, reliability and safety on site. As a holistic solutions provider, we share insights into new digital developments around crane operation at Conexpo 2023. Comprehensive planning, efficient processes and spot-on analysis – all made possible by Liebherr.

The future is straight ahead of us

We are taking a fresh look at the work of tower cranes. This means optimising the processes related to, and carried out by, tower cranes e.g. the lifting of loads from A to B on a construction site. And in doing so, we’re also opening up perspectives on activities beyond the actual tower crane task at hand, and recognising additional potential in terms of crane operators, architects, construction planners and supervisors working together on site. Be part of our journey!

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).Plan: Construction site planning

Accurate planning is essential for a successful construction site.

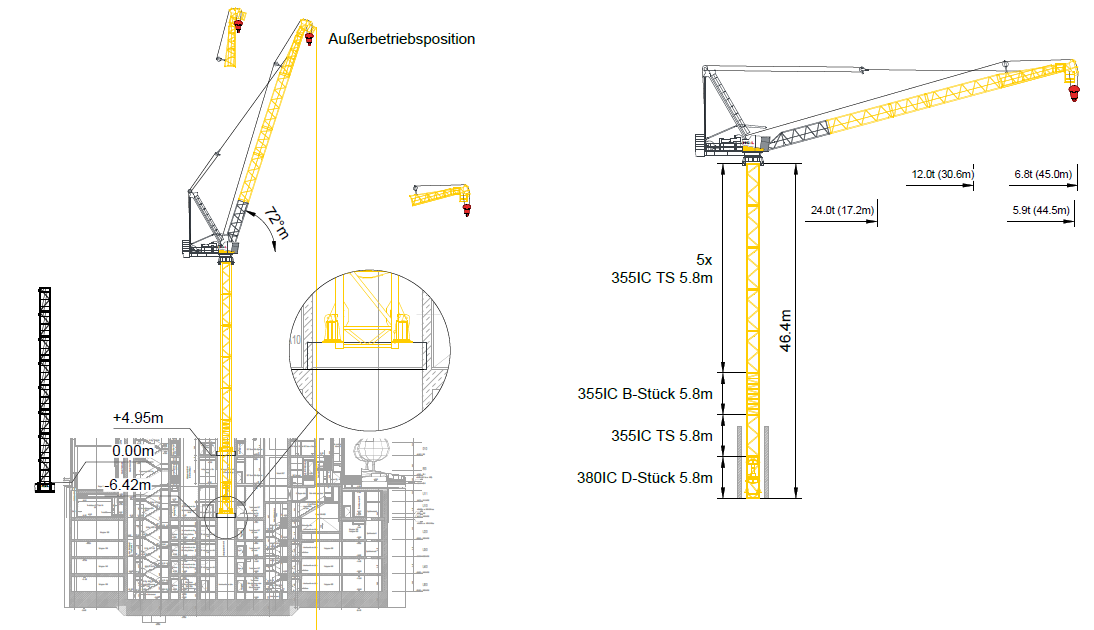

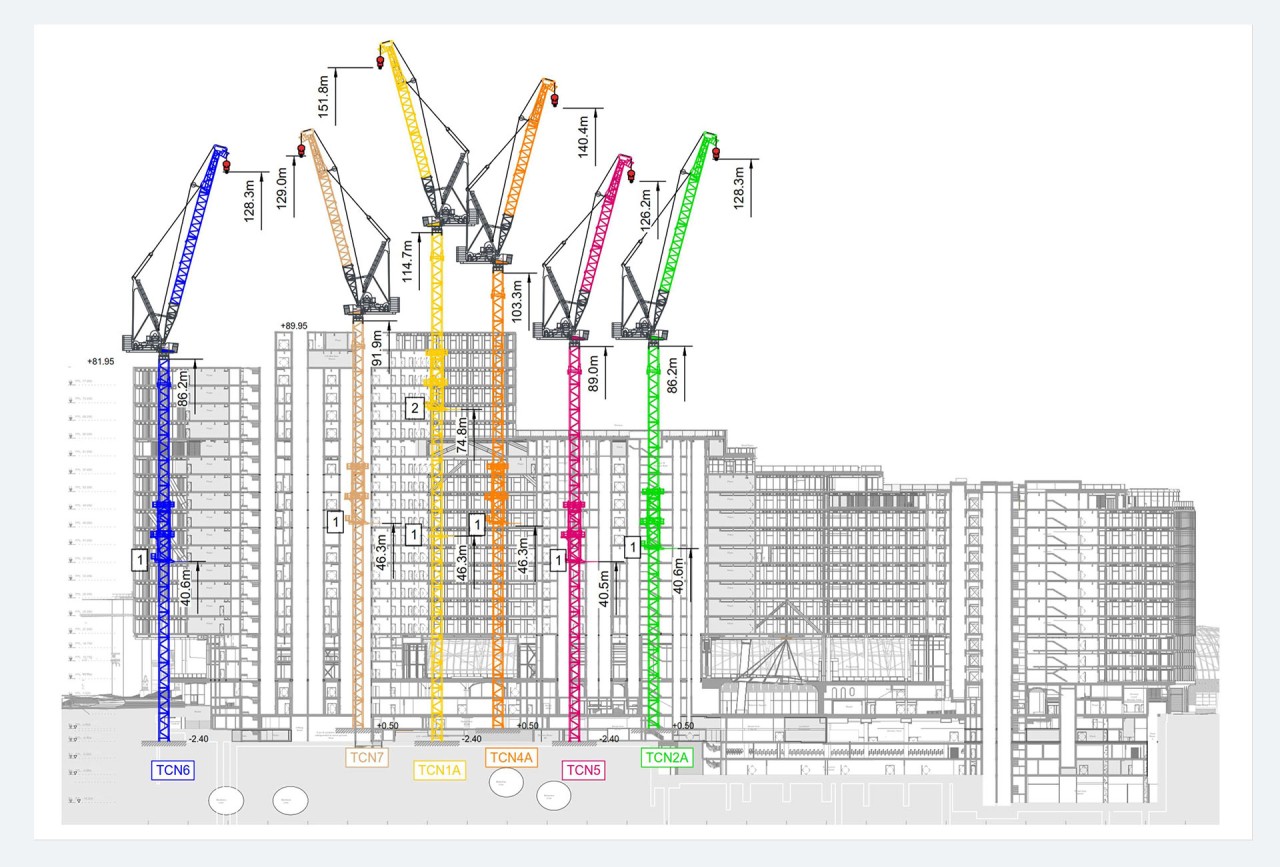

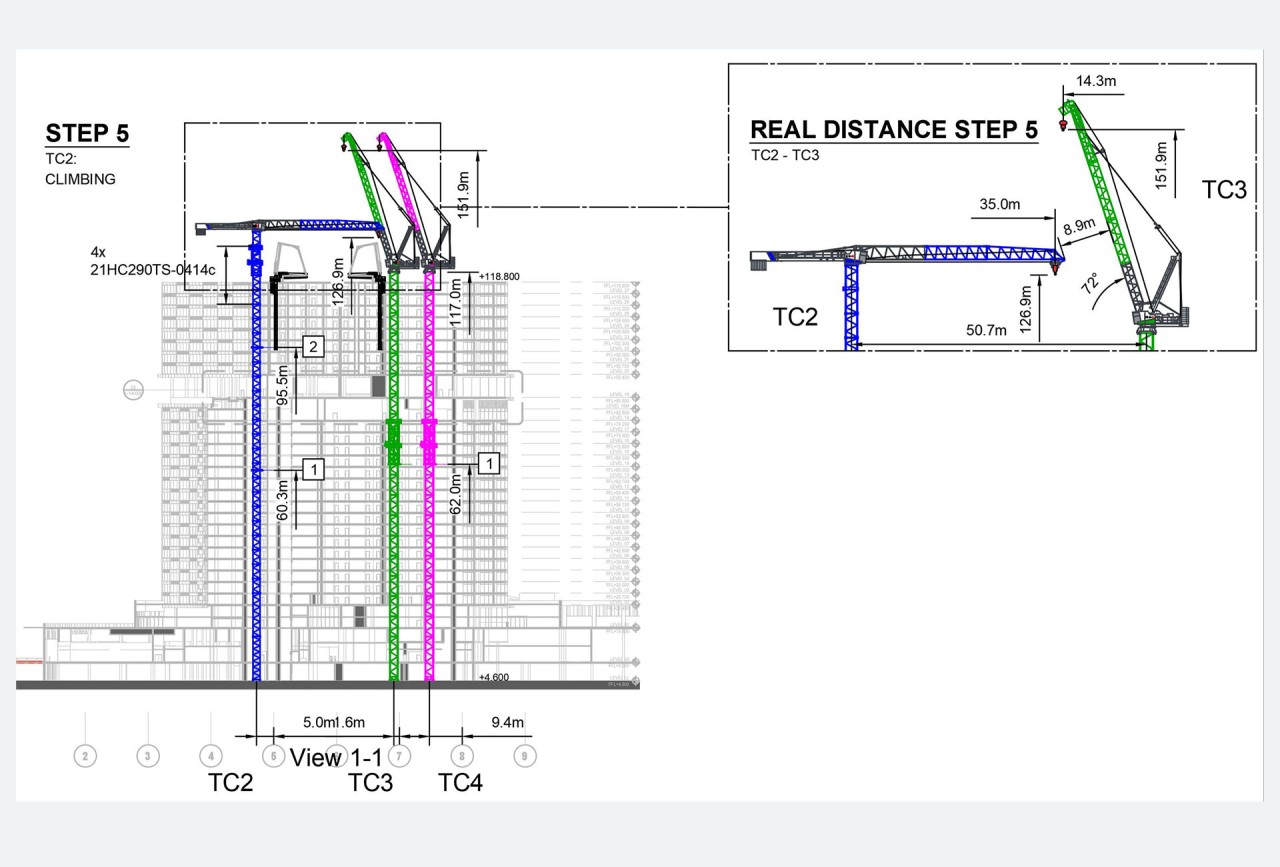

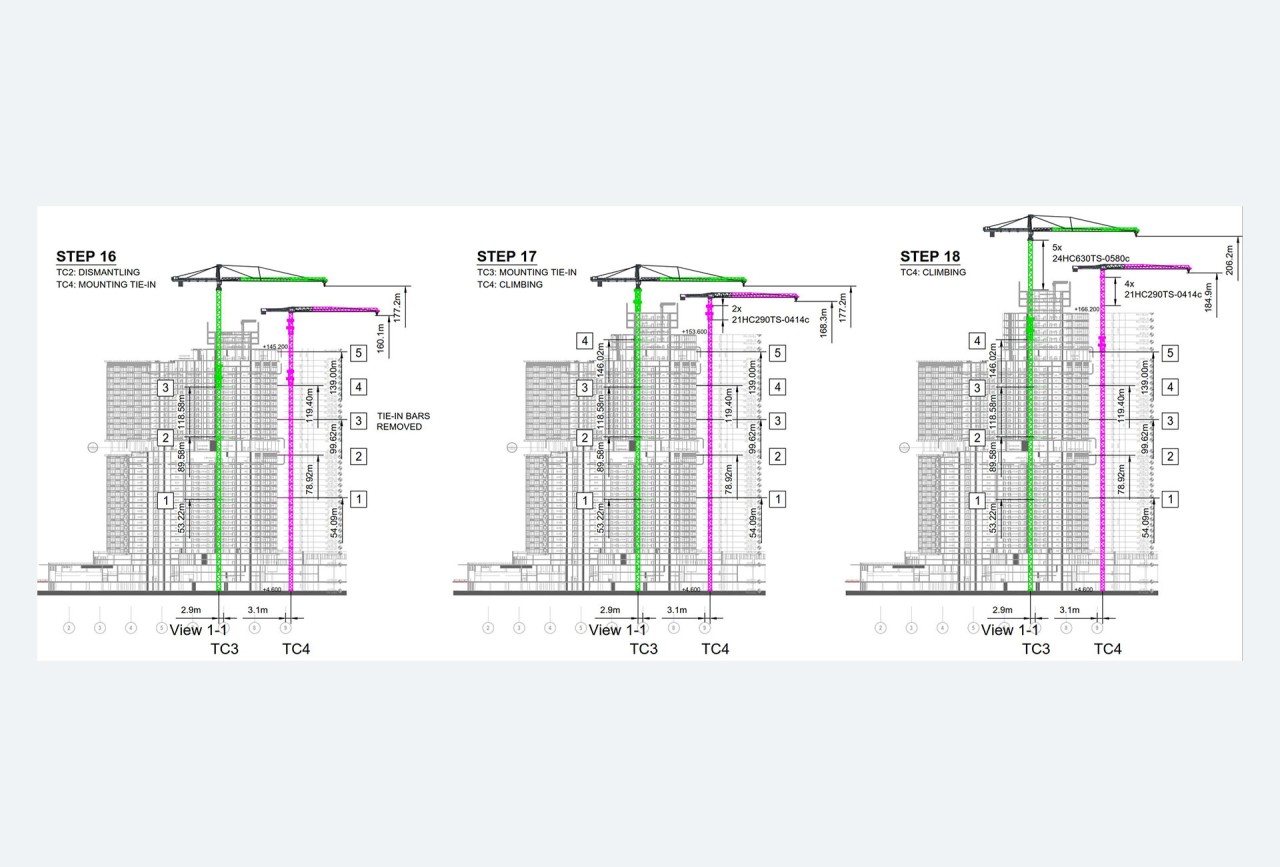

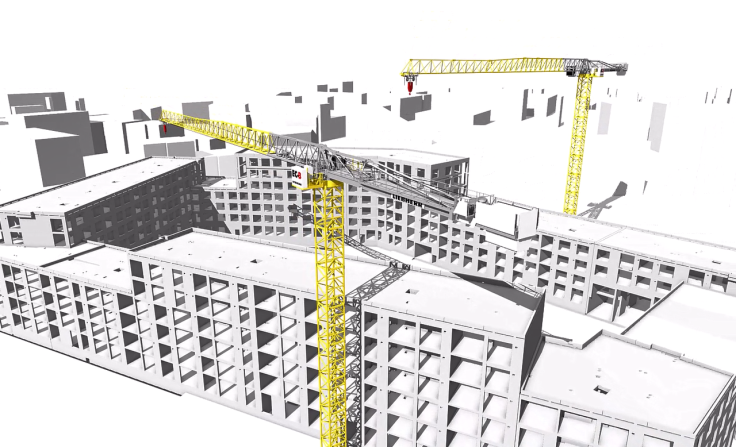

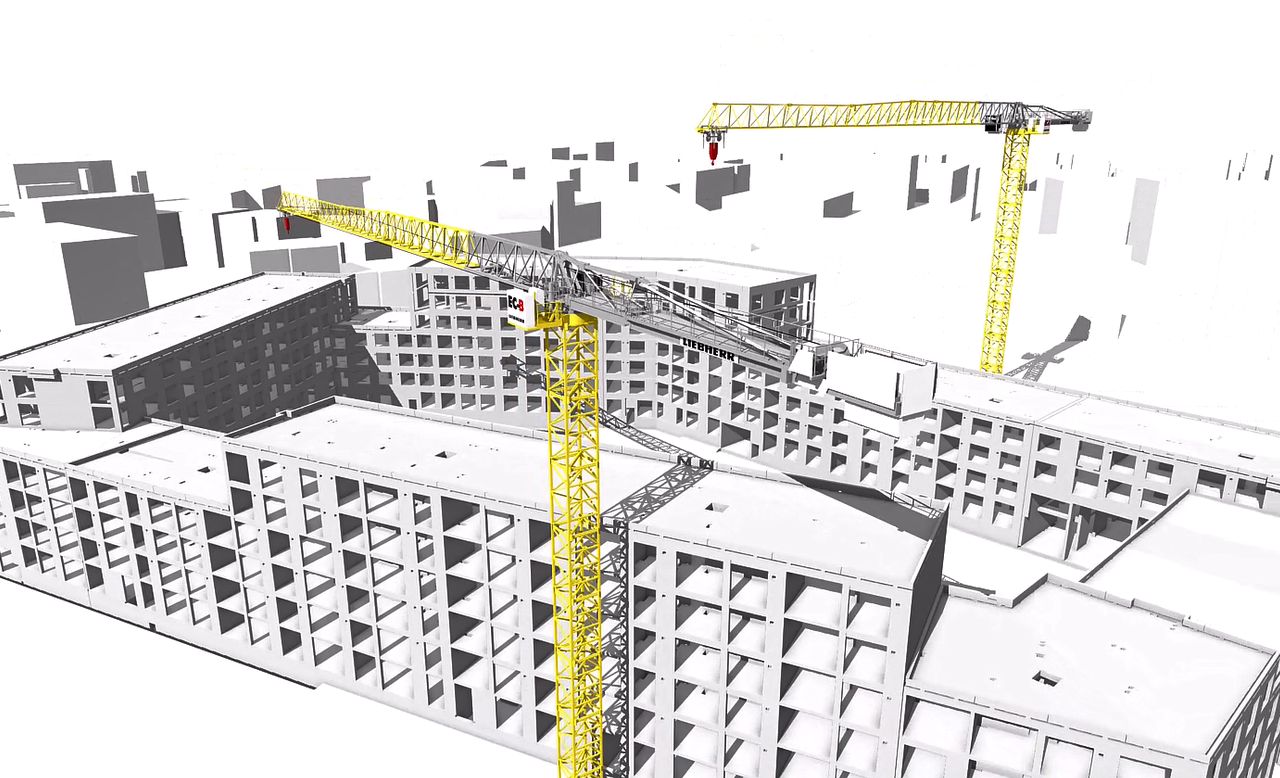

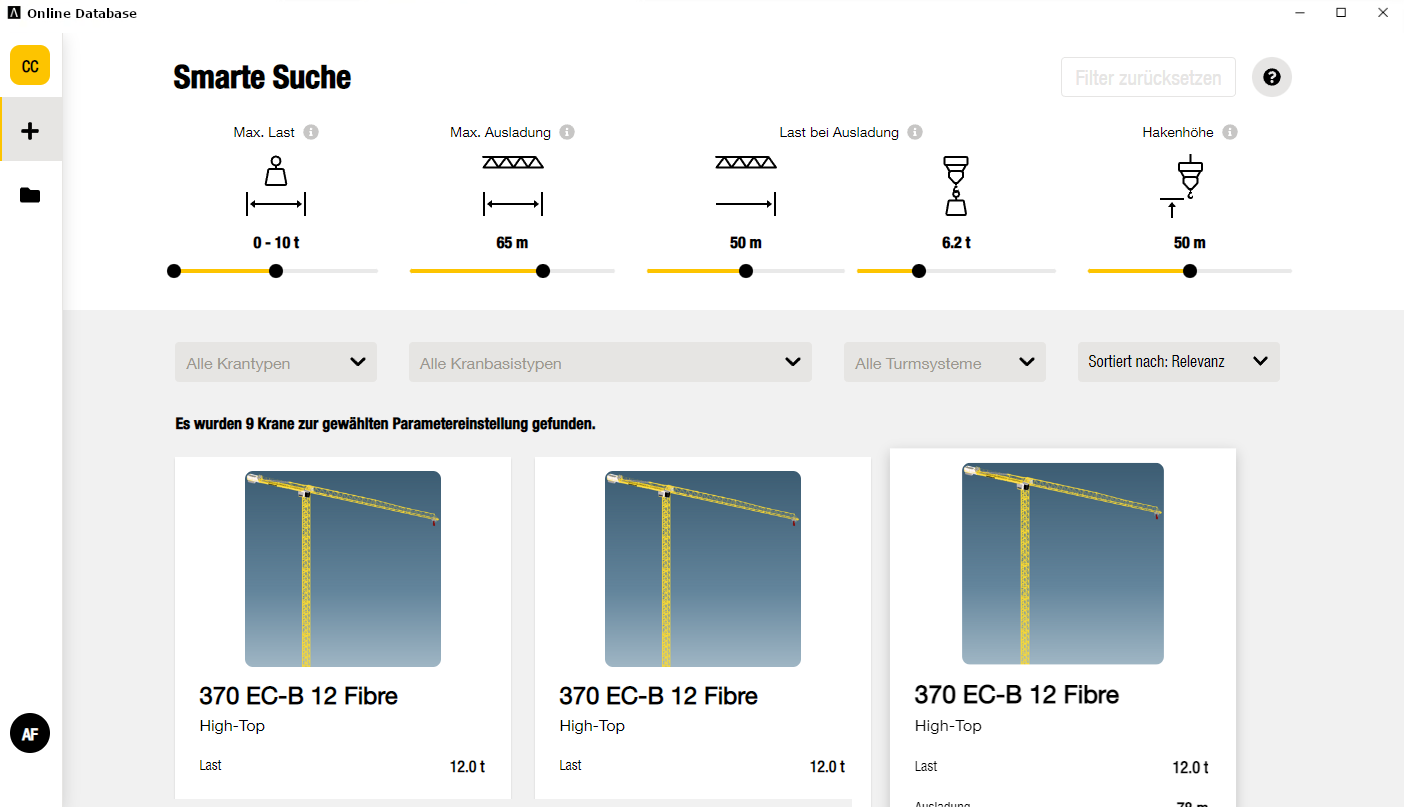

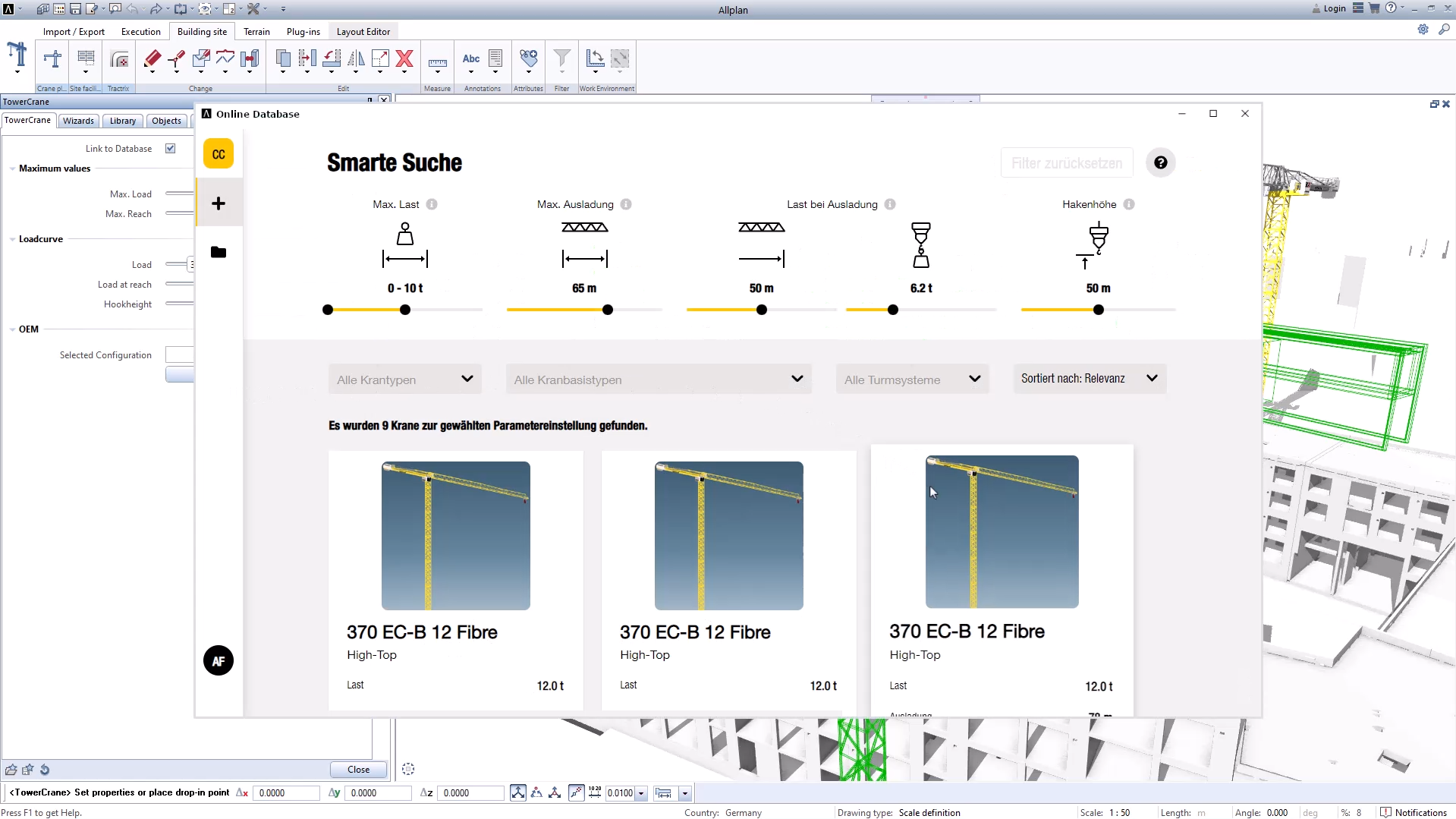

We support architects and construction planners with suitable solutions and services early on in the process. Our PLAN services are primarily geared towards digital construction planning and its planning processes. This means that cranes can be selected to perfectly match requirements and that they can be easily integrated into digital construction site processes. At the core of our planning activities are our comprehensive Crane Information Models (CIM), which we will be rolling out for all our cranes in future.

With appropriate software tools on the user side, CIM models deliver additional advantages:

– Visualisation of the crane working range

– Easier search for optimal crane positioning in digital planning

– Semantic testing and error detection

– Integration into a VR environment

Liebherr also supports planning with customised tools, advisory services and other tailored solutions.

Analyze with Site Monitoring

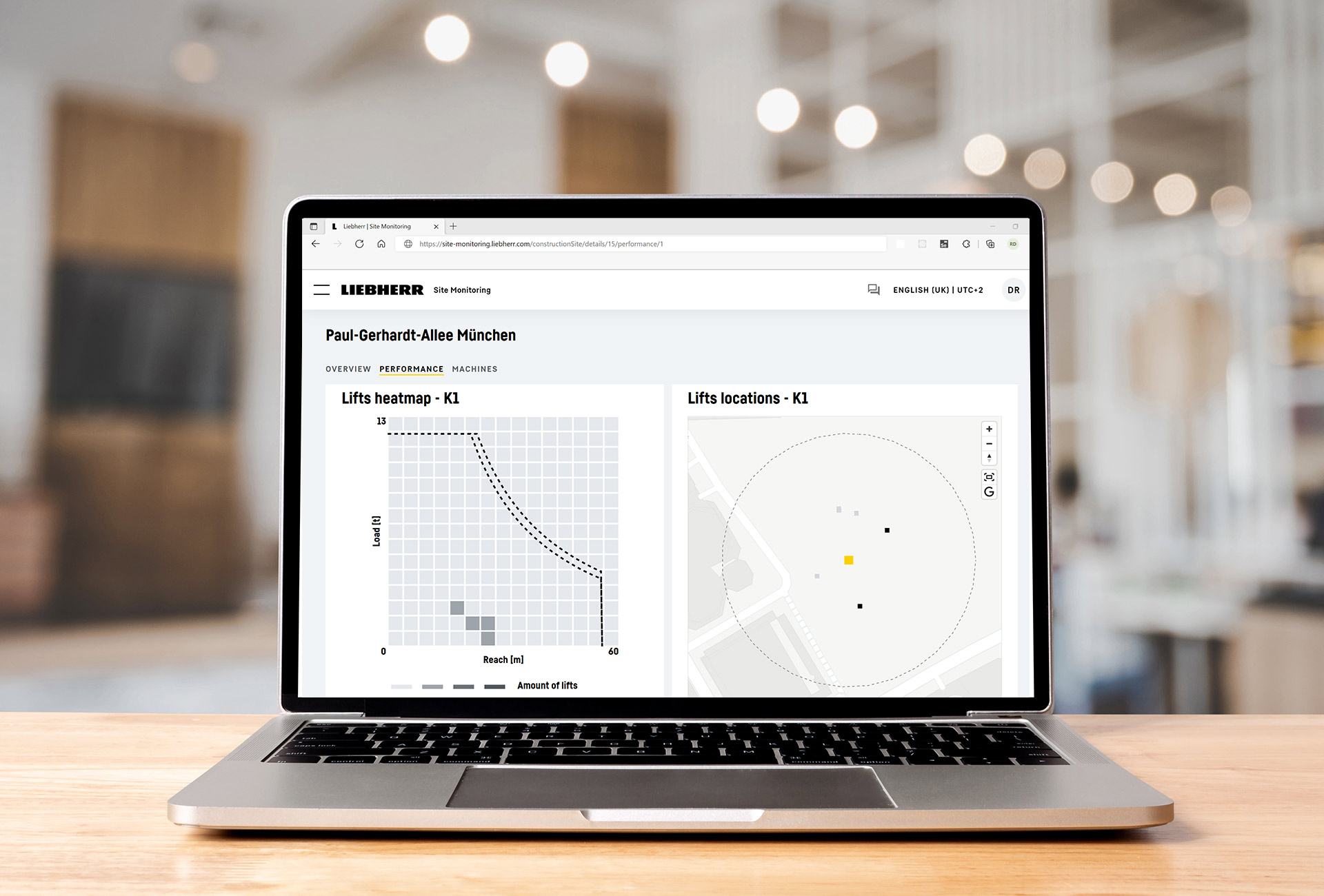

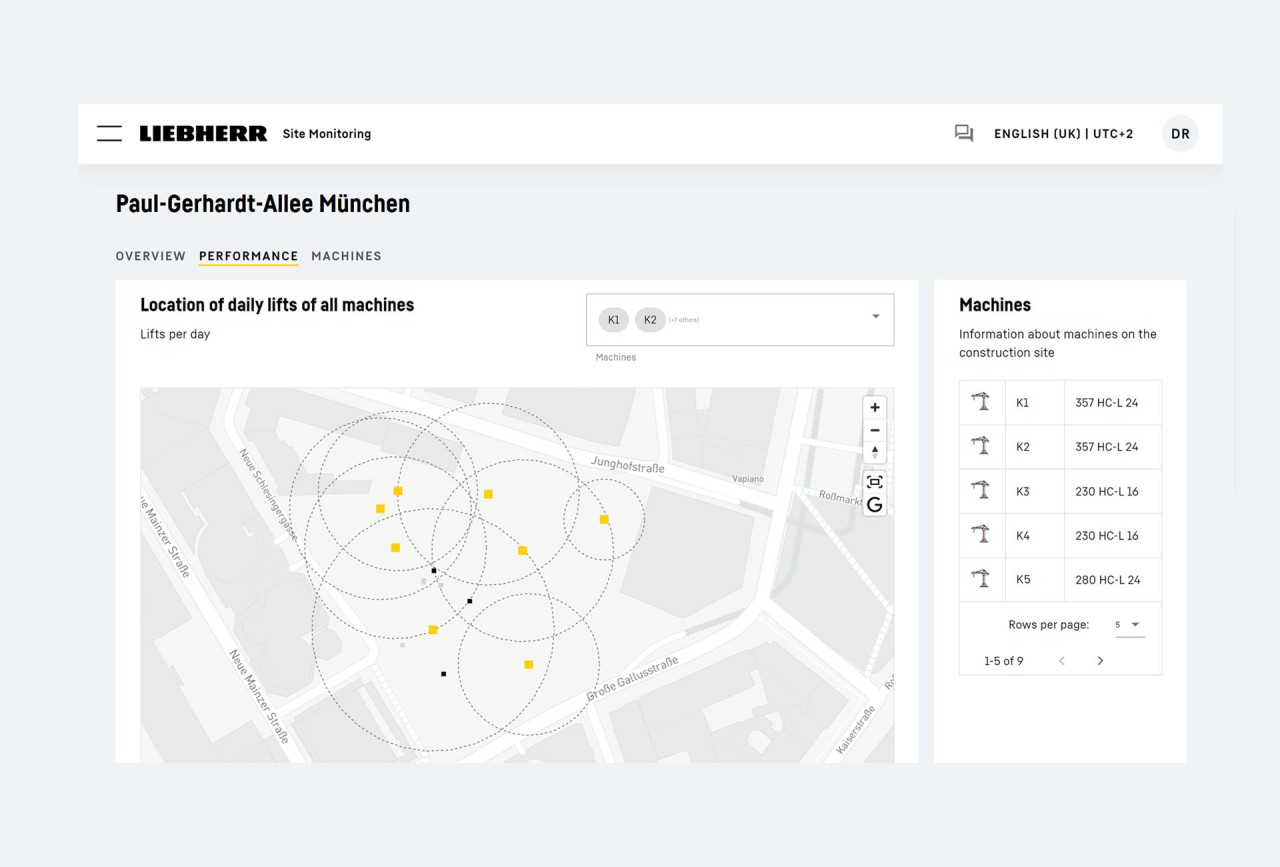

Site Monitoring creates transparency on site

When it comes to load handling, tower cranes are among the most important machines on site. For a project to be carried out successfully, relevant machine and process data needs to be available quickly, and in a clear and comprehensive form. This is exactly what Liebherr Site Monitoring, a digital solution for construction contractors, makes possible:

• Capturing of digital machine and process data

• Information for supervisors and construction planners

• Site diary enhancement with digital lifting data

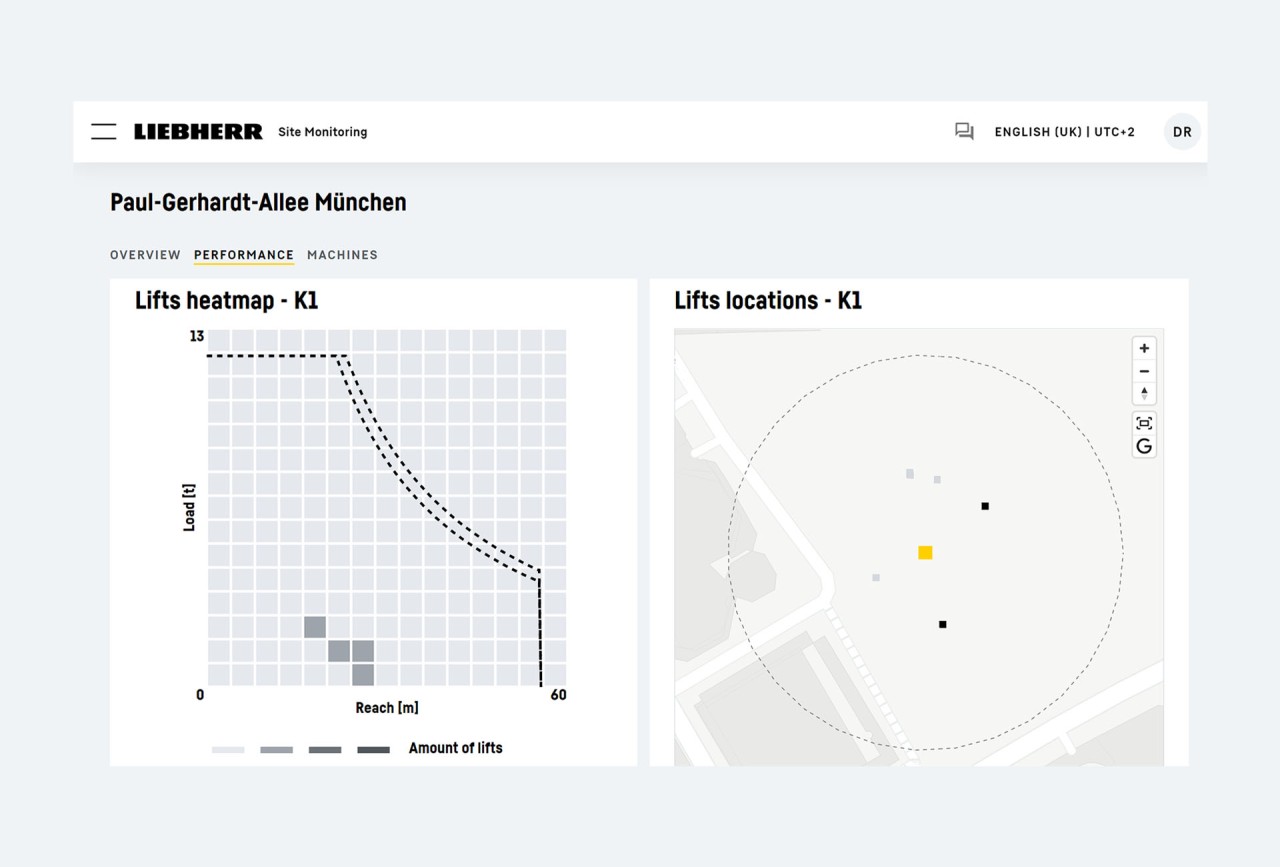

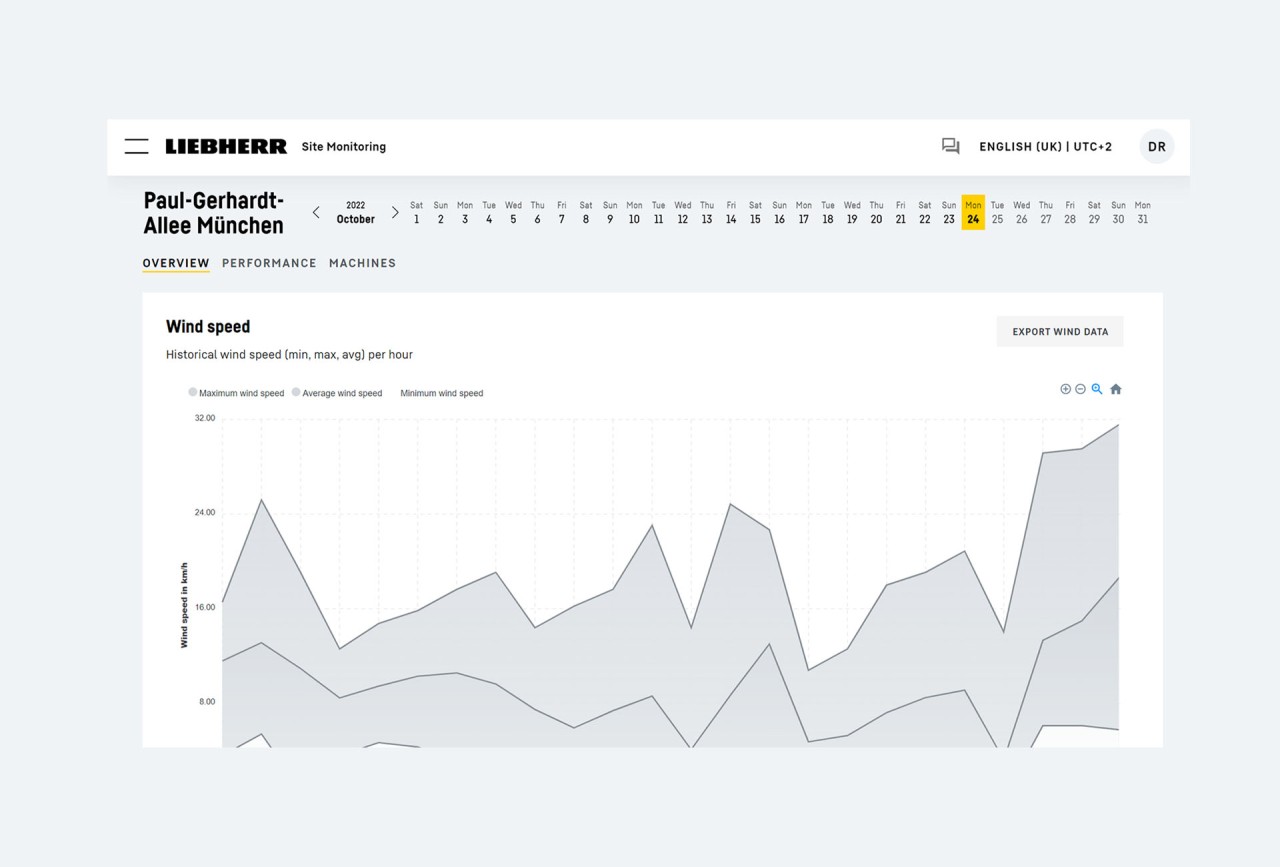

An intuitive interface facilitates the fast display of key information, such as the number of lifts carried out and how optimal these were in terms of their travel path. This provides site managers and supervisors with a basis for their decision-making.

Site planners can use this captured material movement data to check set-ups and related assumptions. The knowledge gained can be used in subsequent construction projects.

The lifting data obtained can also be used to enhance site diaries. Materials moved by the crane can be recorded with further process data for later traceability.

Contact

If you have questions about planning or analysing with Liebherr Tower Cranes please don’t hesitate to contact us via email or give us a call!