4 minutes | magazine 01/2021

Simply explained: TELEMATIK

Florian Trauner, Designer in the Crane Booms Department at the Liebherr Plant in Ehingen, explains the term “TELEMATIK”.

Florian Trauner, Designer in the Crane Booms Department

Revolutionary technology

When they hear the word telematics, most people do not immediately think of a mobile crane, but more about the link between the terms telecommunications and informatics (IT). Although the specialist areas of vehicle telematics and fleet management are absolutely related to our industry, when we talk about TELEMATIK in this article, we are talking about a technology which revolutionised the world of telescopic cranes almost a quarter of a century ago. Florian Trauner, Designer in the Crane Booms Department at Liebherr in Ehingen, explains the terminology and the technology behind it.

The great thing about TELEMATICS is the simplicity of the system.

The Liebherr TELEMATIK system is also made up of two words, but in this case they are telescoping boom and automatic. The technology is the answer to the question of how to extend long telescopic booms quickly and automatically to a required length whilst enabling them to achieve the highest possible lifting capacities. The rope pull technology which was standard at the time, featuring a hydraulic cylinder and pulley block, had reached the limits of its capacity because it would only work efficiently with telescopic booms comprising four or five sections with a maximum length of around 50 metres.

Our first crane with a TELEMATIK boom, the LTM 1160/2, had a 6-section, 60 metre boom as long ago as 1995. Three years later, the LTM 1500 had an 84 metre boom comprising seven telescoping sections – a world record at the time. The open secret of the new technology was that it involved a single cylinder extending and retracting all the telescoping sections – with no ropes at all. The ingenious thing was that this made the almost “empty” boom particularly lightweight.

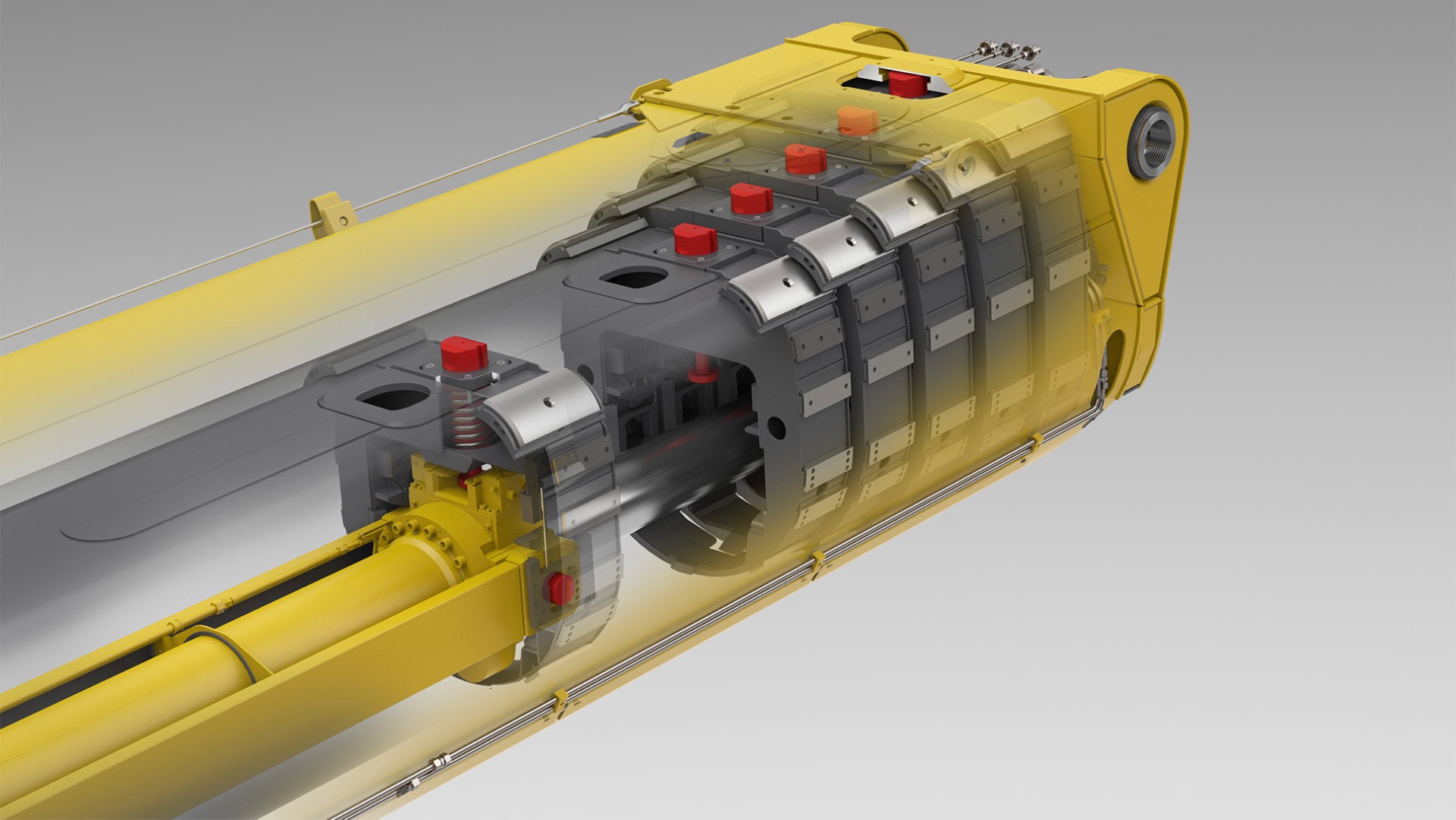

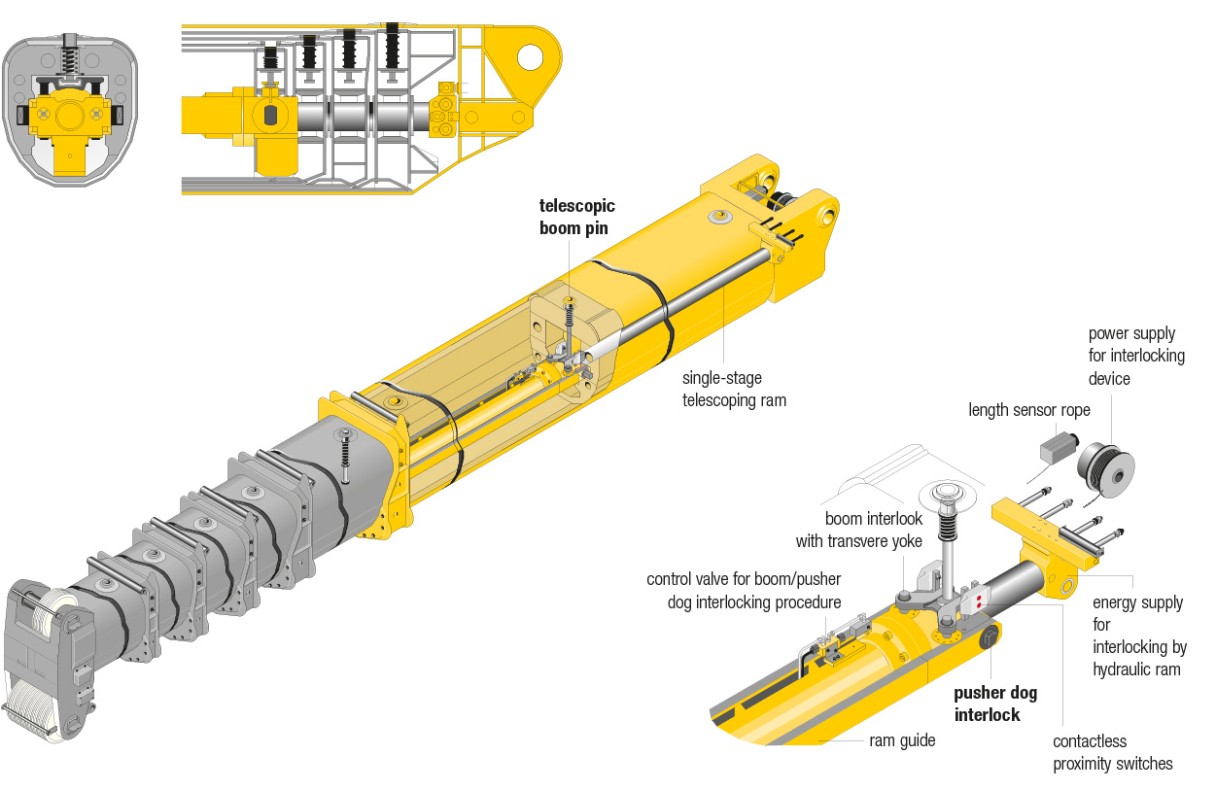

How exactly does it work? At the bottom end of the telescoping cylinder there are pins at both sides (see graphic – “pusher dog interlog”), which engage in the innermost telescoping section to enable it to be extended. After an extension distance of 46, 92 and 100 percent, the telescoping section will find an opening in the upper chord of its direct neighbour into which a powerful pin (graphic – “telescopic boom pin”) is inserted to lock the two telescoping sections to each other. Only when this interlock has been completed successfully can the pins used to connect the cylinder and the innermost telescoping section be released. This ensures a high level of safety.

The telescopic cylinder then travels back “empty” and is pinned to the second innermost telescope. The cylinder then pushes this and the innermost telescope to which it is locked outwards. At 46, 92 or 100 percent, this “package” is then pinned to the third telescoping section. The cylinder can once again travel back empty and the same process is repeated. This is why this process is also known as a cycle system. In theory, this process can be continued infinitely. This is why TELEMATIK does not impose any limit on the length of telescopic booms.

In addition to high lifting capacities with large radii due to the lightweight telescoping system TELEMATIK makes very high values possible with small radii as the telescoping length of the various sections can be selected as required. In other words, the crane operator extends the large outer sections in this case and either does not extend the thinner sections or only does so to a short length. The convenient aspect of this is that after the individual lengths have been entered in the crane control system, the process takes place automatically, including all pinning procedures. The whole thing is monitored by a large number of proximity switches. The complete process is also monitored by the crane operator on the screen.

One of the keys to the success of this system is its simplicity. This is because only mechanical components are required on the moving telescoping sections, with no hydraulic, electrical or pneumatic components necessary. The proof of the success of TELEMATIK booms is provided by thousands of Liebherr mobile cranes featuring this system, which operate reliably all over the world.

This article was published in the UpLoad magazine 01 | 2021.