4 minutes - magazine 02 | 2023

Catch Bar Plus – enhanced safety

As early as the development phase, we take care to ensure that operating errors are eliminated as far as possible during assembly operations on our cranes, or that their effects are kept to a minimum.

Jan Walter is Head of Lattice Jibs and Equipment in our Design Department. He explains how our new Catch Bar Plus delivers even greater safety for installing folding jibs.

If, when mounting the folding jib, its attachment to the telescopic boom is loosened and the jib is swung out before it is bolted to the boom head, there is a risk that the jib will fall down. This is why our telescopic cranes have had a catch bar near the front transport brackets for many years. If the jib collapses, the operator sees and, above all, hears very clearly that he has not completed the assembly sequence correctly and that he must now take appropriate action. If he continues the assembly in this state, the folding jib may even fall off in the worst case.

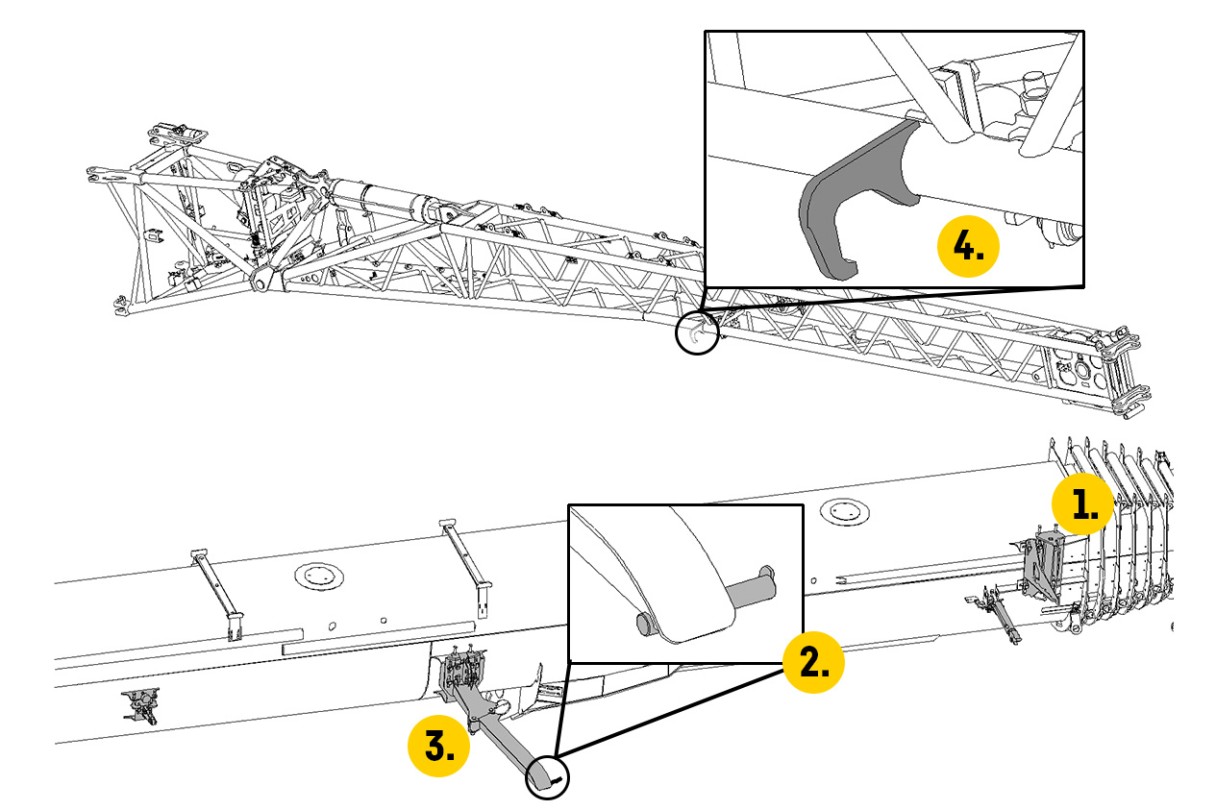

Accident prevented - The jib is suspended on the hook and rod.

Better safe than sorry – Catch Bar Plus

We have improved our system to prevent this and we call the result Catch Bar Plus. First we have modified the front catch bar so that the jib is held more securely by the fastenings. We have also designed another catch bar near the rear transport bracket, which also secures the folding jib. It consists of a hook on the folding jib and a bar on the folding jib support.

Jan Walter - Design and Development Superstructure, Head of Lattice Jibs and Equipment

We have built a special test stand to ensure the function and safety of the new catch bar on all our current crane models. Various operator errors were simulated and we improved our designs on the basis of the test results. We have been delivering cranes with the new system for about a year. In the meantime, we have converted our entire range of telescopic cranes to Catch Bar Plus. This also means that we are already compliant with the latest revision of the EN 13000 standard, which will soon come into force. Among other things, it calls for additional safety when assembling folding jibs.

Our new Catch Bar Plus system makes accidents almost impossible when assembling folding jibs.

However, a word of caution – if old type folding jibs are installed on cranes with Catch Bar Plus technology, then the “plus” in safety no longer applies. We suggest that you only install these folding jibs with an auxiliary crane. This also saves having to adjust the transport brackets to the folding jib, a job which requires a great deal of effort.

Sophisticated - Just a few mechanical parts secure the folding jib to prevent it falling: 1. Catch bar | 2. Rod | 3. Folding jib support | 4. Hook

Unmistakable - Unique short designations make equipment components easy to use-

Short designations facilitate logistics

As the new “Catch Bar Plus” jibs look very similar to the previous ones, we have clearly labelled them with abbreviated names on adhesive labels. This also makes it clear which different jibs may be carried on which cranes. We have also introduced the new abbreviated designations on adhesive labels for other equipment such as lattice extensions. This ensures that you always have exactly the right parts for the job. You will find further information in the operating instructions.

This article was published in the UpLoad magazine 02 | 2023.