6 minutes reading time

A vision of safety

There's no material-handling job too tough for Liebherr wheel loaders. At a recycling plant in Munich, smart assistance systems with innovative sensors, modern camera systems and ‘intelligent’ headlights guarantee optimal safety around the depot.

A visionary with a passion

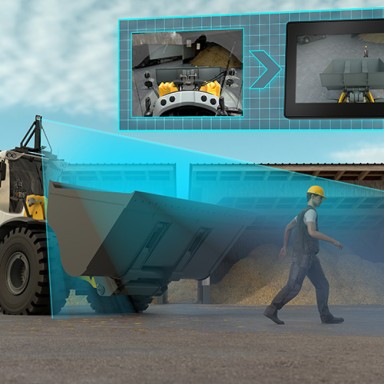

‘My team’s safety is my number-one concern’, says Thomas Breitsamer. Along with his brother Johann, the 48-year-old heads one of the largest recycling companies in the Munich area. To guarantee safety for everyone who sets foot daily on this very busy terrain to the north of Bavaria’s state capital, the visionary entrepreneur relies on technology from Liebherr. He has equipped his L 566 XPower wheel loader with the SkyView assistance system which gives the driver a 360-degree view around the machine at all times. Four cameras from the Liebherr plant in Bischofshofen are installed on the wheel loader, providing the panoramic view that’s displayed inside the vehicle’s cabin. This is crucial for the driver, considering that up to 800 vehicles cross the six-hectare industrial terrain every day.

When it comes to safety, our philosophy has always been to go just a little further than what the law requires.

Developing products alongside the customer

From the moment you enter the terrain, it’s clear that the Breitsamer company handles an enormous volume of material. Countless trucks arrive, carrying fully loaded containers with all types of waste, while the already unloaded vehicles queue up on the way back out of the terrain. The number-one concern on this traffic-heavy work site is the safety of everyone present. The boss is well aware of this, because he also works as the technical manager here, keeping a close eye on the machine park in particular. ‘When it comes to safety, our philosophy has always been to go just a little further than what the law requires.’ That’s why the SkyView system from Liebherr is only the beginning. As a trained electrical mechanic specialised in heavy vehicles, Breitsamer works closely with Liebherr’s product experts in Bischofshofen. ‘Direct feedback from our customers is extremely important for product development’, says Mark Walcher, Product Manager for large wheel loaders at Liebherr. He meets regularly with Thomas Breitsamer and has visited the site numerous times to watch the Liebherr machines in action. ‘We don’t just develop our machines for our customers, but also with them. That allows us to offer the best solutions possible’, explains Walcher.

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).Loads of innovations at Bauma

For Bauma 2019, Liebherr significantly expanded its package of assistance systems. The SkyView and adaptive work lighting systems were both being updated. Adaptive work lighting is a special lighting system that adjusts the brightness of the headlights according to the job at hand. As an intelligent system, the various lighting components switch on fully automatically and only when needed. Just in time for Bauma, this system has been expanded and given an even more user-friendly design. Another innovation is the ‘Remote Control with Coming Home/Leaving Home’ functionality. Using a remote control, the driver can switch the machine to work mode even before boarding it. The work headlights are activated to illuminate the hazardous zone surrounding the vehicle. ‘This saves time and reduces the risk of accidents, especially when working at night’, explains Mark Walcher. This is because boarding and disembarking the machines poses the highest risk of accidents.

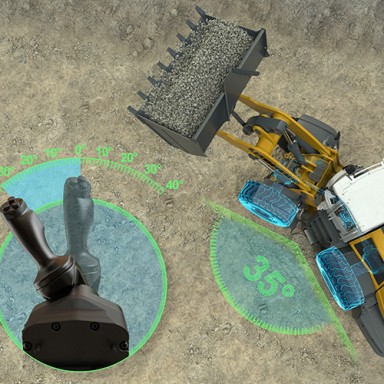

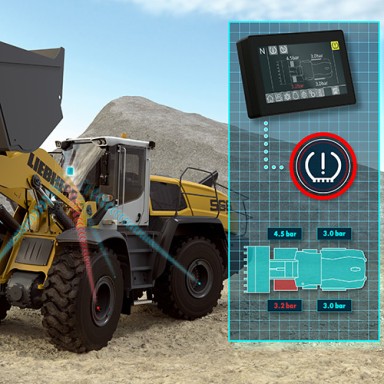

Furthermore, Liebherr introduced four all-new assistance systems designed to support machine operators during their day-to-day work. These include an original active rear-view human detection system developed in-house, a new joystick steering system, an improved weighing device and an integrated tyre-pressure monitoring system. ‘With this package of systems, we are offering our customers even greater safety along with the utmost efficiency’, says the product manager. The new joystick-controlled steering system gives the driver exact feedback about the position of the wheel loader, because the position of the joystick precisely replicates the ramp angle. The sensors of the newly developed rear monitoring system can distinguish between human beings and inanimate objects, warning the machine operator in time, in case anybody is in the hazardous zone behind the machine.

Think-tank for assistance systems

These solutions are all being developed at the Liebherr plant in Bischofshofen, Austria, where wheel loaders have been produced for many decades. ‘Bischofshofen coordinates the full development of driver-assistance systems within the Earthmoving division’, explains Mark Walcher, who has worked for Liebherr since 2009. They started out as beeper systems similar to the ones in passenger cars that warn drivers of obstacles. However, the shortage of specialised workers today has made more complex assistance systems indispensable. Above all, however, the market (i.e. the customers) continue to optimise their supply chains, and this sets new requirements for vehicle development and construction.

Innovative by tradition

Listening to Thomas Breitsamer, you quickly get the impression that you are talking with someone who is running the family business with the deepest respect for his father’s life work, but who is also a visionary who takes a long-term view of the future. Along the way, the business has grown from a sanitation company to an ultra-modern recycling operation in which waste products are used to produce alternative fuels. ‘We see it as our duty as a waste management company to look at the bigger picture and think about what’s next for future generations. That’s why we produce over 30,000 tonnes of alternative fuels from the materials deposited here each year’, explains Thomas Breitsamer, whose company uses three compact L 507 Stereoloaders in addition to its three large wheel loaders. Another two telescopic handlers from the Liebherr plant in Telf and two wheeled excavators from the Liebherr plant in Kirchdorf also perform without fail on the terrain. ‘Here in the Munich area, noise protection and emissions are important factors that have to be considered’, says Breitsamer, who enjoys getting behind the wheel of his Liebherr machines himself whenever he finds the time. Breitsamer is impressed with the design of Liebherr’s machines. ‘They generate very little noise and are extremely fuel-efficient’, he says. Ever the pioneer in the field of waste management, Breitsamer already took ownership of his next Liebherr machine at this year’s Bauma. The brand-new L 580 XPower wheel loader is equipped with an extensive package of new assistance systems to continually meet the company’s needs. ‘Our drivers have a big job to do, so we want to make their lives easier with the right technologies.’