Picking a winner

Wick AG, a leading integrator of robotics systems in Switzerland, was instantly so impressed by Liebherr’s bin picking software that they added it to their portfolio and they are exclusively distributing the software in Switzerland. The open concept of LHRobotics.Vision enables a flexible combination of camera systems and robots from different manufacturers, while also being intuitive and extremely easy to operate.

When searching for a suitable bin picking system, Wick AG had already carried out various tests but had not found a suitable solution until being introduced to the technology package of Liebherr-Verzahntechnik GmbH at the EMO Milan (Italy) in September 2021. “We had given a great deal of thought to the topic of bin picking for quite some time, but had not found a satisfactory system,” explains Hanspeter Müller, Head of Special Projects & Software at Wick AG. “With LHRobotics.Vision, it was different. The large range of functions, the intuitive operation and the reliable parts recognition impressed us immediately.”

Open concept with smart software LHRobotics.Vision

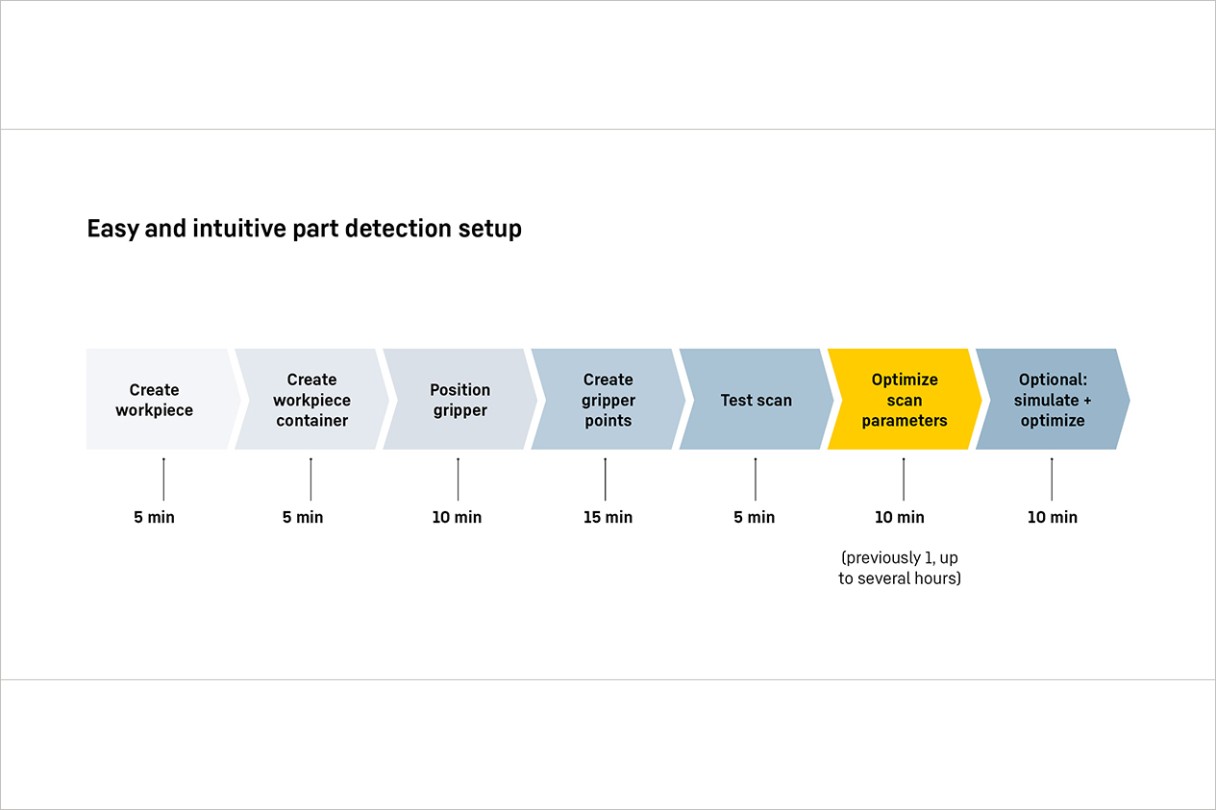

The LHRobotics.Vision software is a component of a technology package for bin picking, i.e. robot-supported removal of unsorted parts from a container. The smart solution is available in two functional scopes: The basic license includes scanning and gripping, while the professional license also includes the stacking plan. The possibility of simulating processes is also available as an option, and all presented on a clear, intuitively operated interface. A Zivid camera system is integrated into the package as standard, but the system also allows the easy integration of sensors from other manufacturers.

Award for top innovation of 2023

“We place great importance on an open concept which enables maximum flexibility for users and integrators,” explains Jürgen Groß, Head of Sales for Cells and Flexible Manufacturing Systems at Liebherr-Verzahntechnik GmbH. Optionally, search parameters for parts can be automatically optimized with the aid of artificial intelligence (AI). This reduces the setup time to just a few minutes. In March 2023, the software with this feature was given an award by the trade magazine inVISION as one of the top innovations of 2023 for industrial image processing systems.

Stable, smart automation system

The many advantages of LHRobotics.Vision persuaded Wick AG to add the software permanently to their own portfolio. Hanspeter Müller explains the advantages of the software: “It extends our solution range by providing real added value for our customers. For example, the mechanical separation with vibratory bowls is replaced by a more stable, smarter automation system.” Initial discussions about a distribution partnership took place in May 2022, a cooperation agreement was drawn up in August 2022, and the developer package was ordered at the same time.

Building success together at the trade fair (from left to right): Björn Urland (Sales Manager Bin Picking), Agnes Schauppel (Product Manager Automation Systems), both Liebherr-Verzahntechnik GmbH, with Guido Lüönd (CTO), Nicolas Brahier (CEO), both Wick AG

Workstation implemented in a very short time

Wick AG’s aim was to present the software in September 2022 at the Ble.CH trade fair in Bern (Switzerland), an ambitious deadline. The integration and implementation took place in record time. After just one day’s training by Liebherr, a simulation workstation, consisting of camera system and bin picking container, was set up and mounted within one week. The response to it at the trade fair was very positive. “In the future, we want to attend trade fairs with an exhibit including robots,” explains Hanspeter Müller. “This will enable us to show live, how well the system actually works.”

Tests and feasibility studies

Both Wick AG and Liebherr offer customer tests and feasibility studies to remove any doubts or uncertainties. “We know that we can count on Liebherr’s professional support and expertise for this,” Hanspeter Müller emphasizes.