From gear cutting to complete machining

Conventional turning and milling machines can perform gear cutting, albeit with limited productivity and accuracy. But are gear cutting machines also able to turn and mill? With Liebherr machines, upstream and downstream processes can be integrated. The LHGearTec programming and user interface, together with the Siemens control system, enables a continuous simulation and programming of all machining steps.

The gear cutting process is always at the center of machining. Before a gear is machined, however, process steps are required which are normally achieved by upstream turning machines or machining centers. For example, the blank is first turned on the shell surface, bores are applied to the front side or slots are milled. Frequently, the gear or spline to be subsequently generated must be aligned with these features.

Turning, milling, drilling

Although gear cutting is always at the focus of machining, Liebherr gear cutting machines can integrate upstream process steps such as turning, milling and drilling. To do this, first the necessary turning tool, mill tool or drill is loaded into the main spindle using a tool changing system and the corresponding machining is carried out. At the same time, the reference contours of the workpiece can already be created for later gear cutting, thus omitting the measurement of the externally prepared partly-machined workpiece using a measuring probe or inductive sensor. This saves time since the gear machining can begin without further intermediate steps.

Deburring and chamfering

Downstream processes can also be realized in the gear cutting machine. For less accessible gears, the FlexChamfer unit is recommended, which with simple shank cutters can not only deburr a workpiece in parallel with the machining of another workpiece, but can also chamfer with a targeted profile. This means that the chamfer can be both freely programmed and automatically generated from the data of the defined gear geometry. For complex, collision-prone workpieces, Liebherr offers an engineering service of calculating the specific chamfer program. As well as chamfering, the FlexChamfer unit can also carry out final engravings or markings.

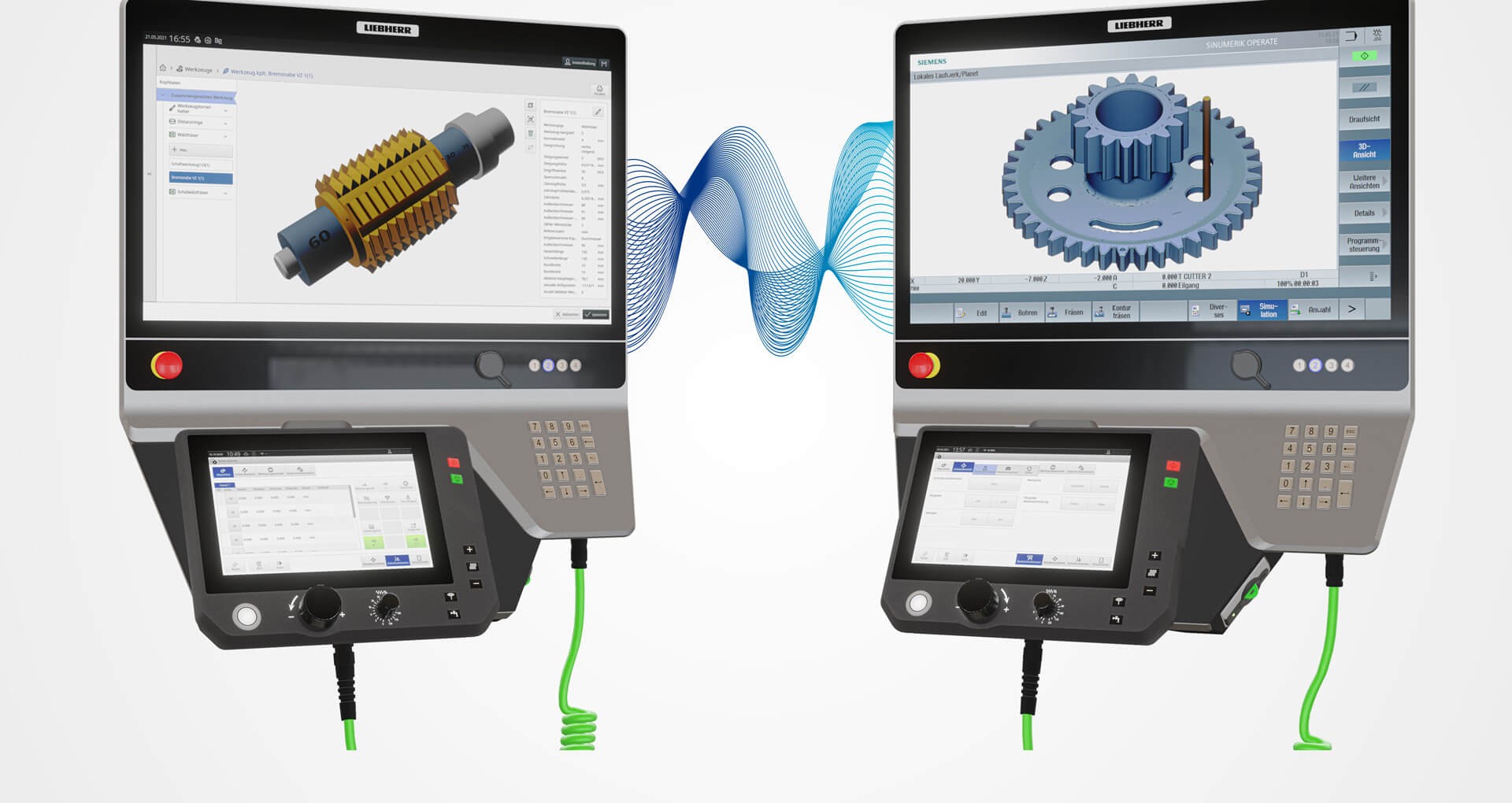

User-friendly programming and simulation

All additional machining is programmed in a user-friendly way on the basis of the downstream Siemens control system (SINUMERIK 840Dsl/ONE) in DIN/ISO G-Code with the available cycles, graphically supported by the Siemens programming system programGUIDE on the HMI Operate.

The LHGearTec control system, in connection with the Siemens center, offers a unique simulation chain for upstream or downstream secondary processes: already during the work preparation, gear cutting can be parametrized on an office PC in one programming station version – exactly as at the machine. This means that the programs can be developed at leisure, which enables a more precise adjustment of the individual, geometry-determining parameters than in the generally more hectic machine environment. The result of the gear cutting can be checked using a 3D model, which can subsequently be further observed in the emulated Siemens control center. All additional operations can be carried out virtually and the gearing situation can be checked using this model.

With the aid of continuous simulation, Liebherr is closing the gap between gearing and “non-gearing” and enabling not only a combination of both worlds but also an efficient work preparation and quick retraction of complex workpieces.