Mining

MiningPress releases | 02/10/2025

Twelve years, four generations, 100% robustness

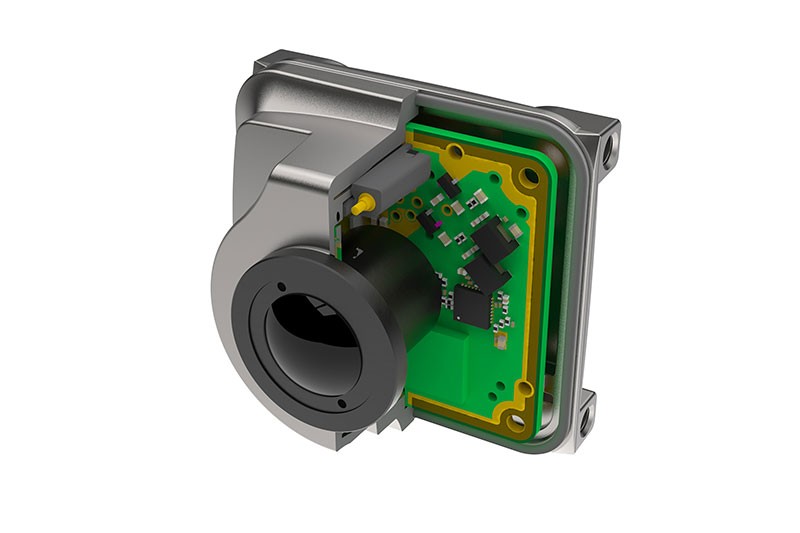

- Liebherr's components product segment presents the MDC4, the fourth generation of its digital cameras

- The camera’s mechanical design is so robust that it reliably delivers crystal-clear images, even under demanding environmental conditions (ice, snow, vibrations, etc.)

- Full HD image resolution of up to two megapixels and the camera's colour resolution ensure an outstanding level of detail. This enables machine drivers to recognise people and objects even from a great distance

With the MDC4, Liebherr's components product segment presents the fourth generation of its digital cameras for mobile machines. Based on over ten years of experience with digital cameras, the new camera has been designed to meet user requirements in terms of robustness, image quality and size. The image resolution also paves the way for the implementation of data-driven AI applications.

Baden (Switzerland), February 10, 2025 – Agricultural, forestry, construction and municipal machinery is exposed to extremely harsh environmental conditions every day. The components that are integrated into these machines need to be as resistant as them. Liebherr-Components has been developing digital cameras for more than ten years. These are used in the Group's construction equipment, as well as in third-party equipment from other sectors. Not only do they need to be tough, the components should also last as long as the machines, in which they are installed. Thanks to Liebherr's obsolescence management, customers can always rely on the long-term availability of spare parts. This does not only provide for planning security, but also saves money.

“A major advantage for our customers is certainly the fact that we have an in-depth knowledge of the demanding operating conditions, in which they use their machinery,” says Alexander Bertsch, head of the sensor technology product line at Liebherr-Electronics and Drives GmbH in Lindau (Germany). The fourth generation combines all this experience in a single product, setting new standards in robustness and image quality – on a five-by-five-centimetre surface, without glass.

Active heating for fast machine availability

Ruggedness means that a camera must deliver a good image quickly and reliably in all weather conditions and extreme environments: whether in sunlight, ice or shade. The camera's mechanics are designed to meet these specific requirements. Even in freezing temperatures, the camera provides reliable support for the machine operator. The camera lens is equipped with an active heating system that warms the iced surface. This allows operators to start working immediately without delay. To withstand the intense vibrations that mobile machinery is exposed to, all electronics are housed on a single circuit board. This eliminates board-to-board connections, significantly reducing the risk of malfunction. A membrane on the back of the camera proactively compensates for pressure differences, preventing condensation, minimising the load on all seals and ensuring long-term availability at the same time. Moreover, the connector is integrated in the unit, actively preventing the possible penetration of moisture and wetness.

Image quality paves the way for convenient assistance systems

In order to work safely – on construction sites, for example – it is crucial that the image quality of the digital camera on the machine is so high that the machine operator can reliably distinguish people and objects from a greater distance or in poor lighting conditions. The higher the image quality, the easier and more comfortable it is to recognise details. This makes the daily work of the machine operator less strenuous. In addition to the resolution in pixels, factors such as readjustment in changing light conditions and colour recognition algorithms are also relevant for image quality. The MDC4 camera sets new standards here: Full HD resolution of up to 2 megapixels does not only improve detail recognition, but also generates more image data. By combining and analysing this image information with other sensor data, it is possible to implement applications based on artificial intelligence. A good example is the recognition of people and objects on construction sites or the creation of application maps for fertilisation and crop protection in agriculture (precision farming). Looking to the future, the MDC4 digital camera is equipped for all future requirements on the way to digital transformation - from digital assistance systems to full machine autonomy.

Time and cost-saving configuration

Besides robustness, one further important criterion in the development of the new camera generation was to make configuration and commissioning as easy as possible. Camera parameters can be configured, using a simple protocol, which is provided to customers at no additional licensing cost. To minimise latency, image data is transferred via a 100 Mbps Ethernet interface.

The new digital camera is also available as a system solution in a 360°-surround-view version and will be on display at the Liebherr Components’ booth 326 in hall 4 at this year's Bauma from April 7 to 13.

Contacts

Liebherr-Components AG

5400 Baden

Switzerland