Group

Group

A stroke of logistical genius

The HafenCity urban development programme in Hamburg (Germany) includes the construction of the new Überseequartier District. A fleet of 25 Liebherr tower cranes are helping to move the project forward with the construction of four different buildings. From office towers and residential buildings to cinemas and shopping centres - this large-scale project has it all. The project planners are relying on Liebherr’s Tower Crane Solutions Team for consultation and support throughout the planning and implementation stages. Thanks to their input, the parallel use of tower cranes on the project has been a stroke of logistical genius.

World premiere in the UK

Under a strategic partnership with Leica Geosystems, the Liebherr R 934 crawler excavator is the first in the world to be equipped ex works with a 3D machine control system. The crawler excavator was delivered to the British company Brad Pave. Laser-assisted technologies provide the 3D machine control system with tilt and rotation functions that enable the Liebherr hydraulic excavator to work even more precisely and efficiently. By installing this system at the factory, Liebherr can ensure maximum reliability whilst minimising downtime on the work site.

The future of refrigeration and freezing

Design meets functionality with the launch of Liebherr’s new generation of refrigerators and freezers. These new appliances include smart features as well as powerful technical innovations to optimise energy efficiency. Quality, durability and sustainability were the guiding principles of their design process. All features are specially designed to meet customer needs and ensure a long product lifespan.

Successful railway industry certification

Liebherr Transportation Systems (China) Co, Ltd, which opened in 2020, has officially received its International Railway Industry Standard (IRIS) certification. The company is now certified to design, produce and maintain transportation technology systems and components. This allows Liebherr to expand its presence in the railway sector in China and other Asian countries.

60 years of hospitality

In the 1950s, company founder Hans Liebherr fell in love with the town of Killarney in south-west Ireland. He eventually opened The Europe Hotel there in 1961. Over the past six decades, this Liebherr hotel has become one of the leading establishments in the Irish and international hotel industry. Today, ‘The Europe’, which offers panoramic lakeside views of Killarney’s Lough Lein, is renowned as one of Ireland’s finest 5-star hotels.

The long-awaited Covid jab

In April, Liebherr began offering Covid vaccinations in the workplace at the location in Ehingen (Germany). The Ministry of Social Affairs of the German State of Baden-Württemberg selected the factory as a pilot company to lead in the vaccination campaign. Company doctors and qualified volunteers from the workforce teamed up with the district vaccination centre in Ehingen to set up the vaccination programme. Other Liebherr sites in the region now also offer Covid jabs to employees and their families.

Electrifying

“It takes bravery and an open mind to break new ground,” said Gerhard Frainer, Managing Director of Sales at Liebherr-Werk Nenzing GmbH during the ESTA Awards ceremony. Liebherr received an award in the Innovation Manufacturer category for the world’s first battery-powered crawler crane. The ESTA Awards are the highest honour within the crane and heavy lifting industry. With the LR 1250.1, Liebherr offers its customers an alternative drive concept that meets even the strictest environmental regulations for construction projects. The crawler crane is exhaust-free and emits very little noise.

High-tech handling for a Swiss natural product

The Liebherr LH 60 M Port material handling machine will have a very special mission in future: It will play a key role in quarrying Brienzer Sand®, a natural product found only in the area surrounding Lake Brienz (Switzerland). Equipped with a special Liebherr clamshell grab with water slots, it is ideally equipped for the special conditions site. The LH 60 M Port is expected to handle up to 80,000 tonnes of natural sand and gravel a year from the nine-metre-deep harbour basin.

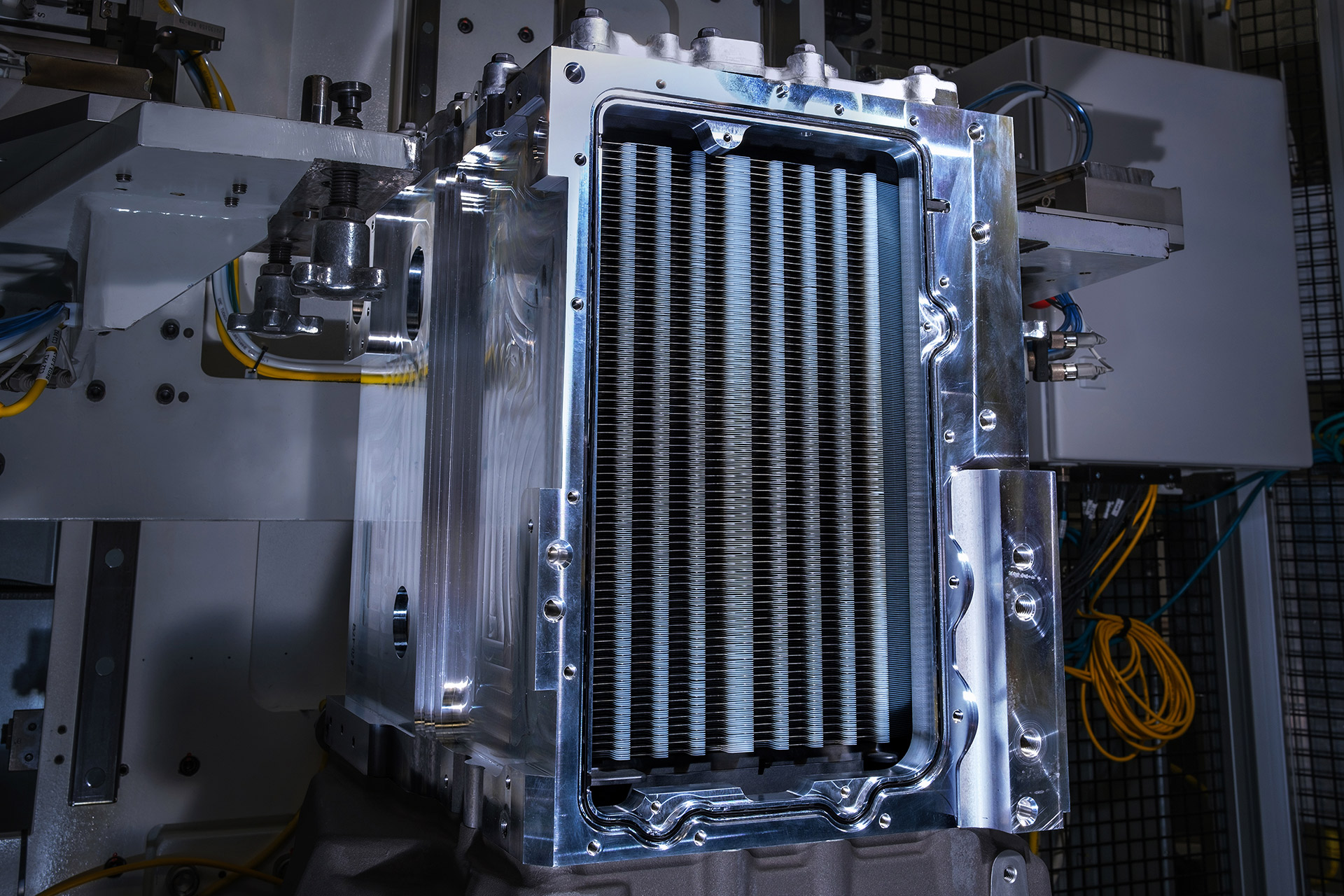

Hydrogen fuel cell technology for aviation

Liebherr-Aerospace and General Motors have signed an agreement to develop a hydrogen fuel cell-based power generation system for the aviation sector. The two companies are pooling their expertise for this innovative new project. Liebherr is an expert in integrating different aircraft technologies, whilst General Motors is the leader in the field of fuel cells. Together they are working on a low-emission solution that will offer an alternative to combustion engines for aviation in the future.

The duty cycle crawler crane that changed Liebherr

After 40 years of service in Nenzing (Austria) the first Liebherr HS 870 cable excavator has returned to its place of origin. This legacy machine, which was unveiled to the world at Bauma in 1980, was completely restored by a team of mechanics, fitters and engineers. Now guests and employees at the location in Nenzing can admire this impressive piece of Liebherr company history.

Fuelling Liebherr machines with hydro treated vegetable oils (HVO)

HVOs are an important component of Liebherr’s mission to develop alternative drive concepts. That is why the Liebherr plant in Ehingen is converting to HVO fuel. This means that HVO will be used during test runs and hand-overs for all mobile and crawler cranes as well as the first refuelling of the machines before delivery. HVO is derived from cooking oil waste, grease residues, waste fats and vegetable oil and generates significantly lower emissions than fossil diesel.

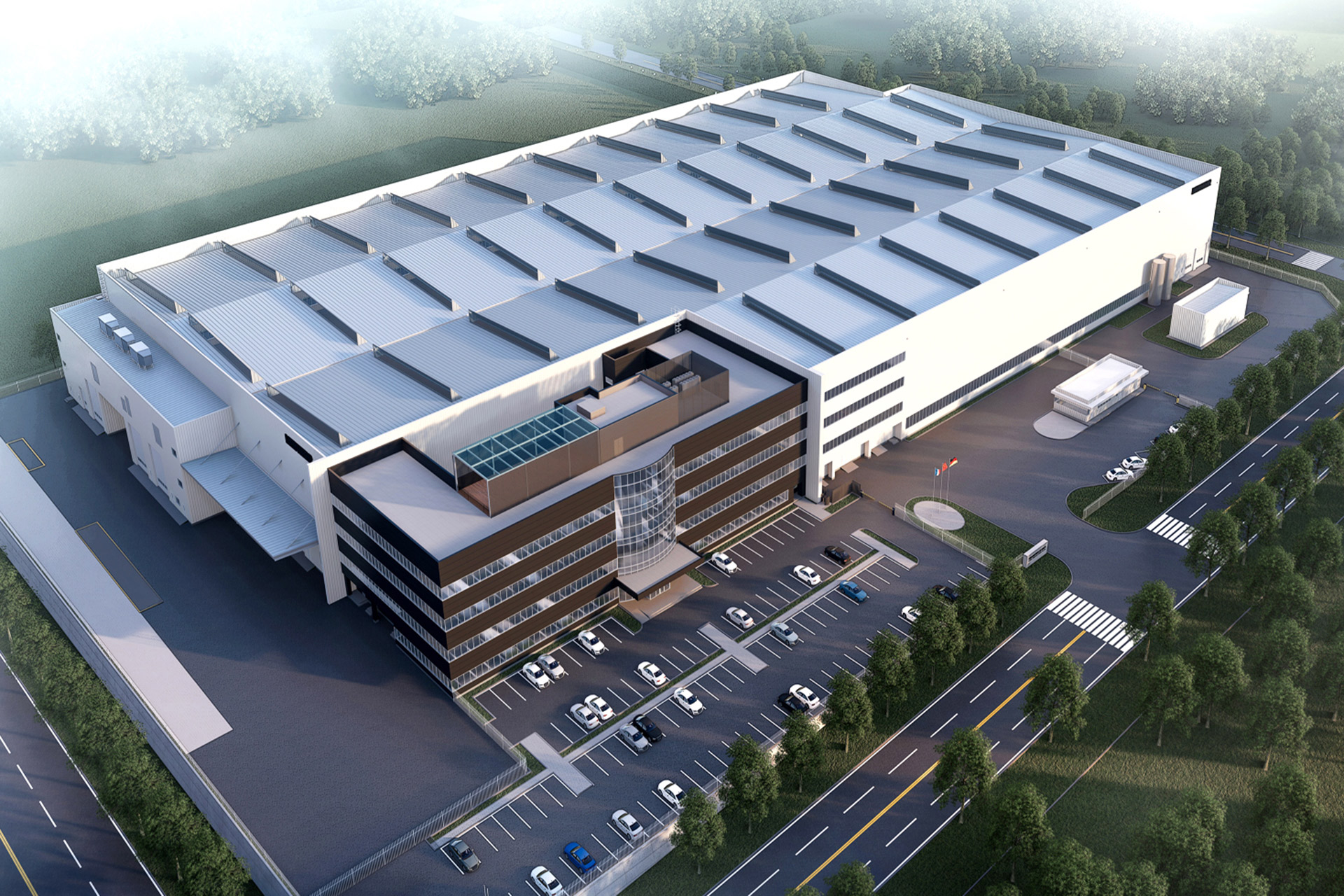

New components plant in China

Liebherr-Component Technologies AG is expanding its presence in Asia with the construction of a new plant in Dalian (China). The plant will be operational by the end of this year and will produce slewing bearings, gearboxes and hydraulic cylinders to meet the growing demand for components in China’s wind power and construction machinery sectors.

Innovations at MINExpo 2021

For the sixth time, Liebherr takes part in MINExpo in Las Vegas (Nevada/USA). During the event, the company presented state-of-the-art machines, technologies and services from its mining, mobile and crawler cranes and components product segments. The hybrid expo gave visitors a chance to experience Liebherr’s latest occupational safety and environmental protection solutions both in person and online.

Jack of all trades

The versatile new 36 XXT truck-mounted concrete pump was launched with a wide range of innovative new features. This compact machine is equipped with the new Powerbloc drive unit, which offers maximum performance with minimal noise. Thanks to weight optimisation and innovative technology, the pump is ideal for working in difficult-to-manoeuvre locations.

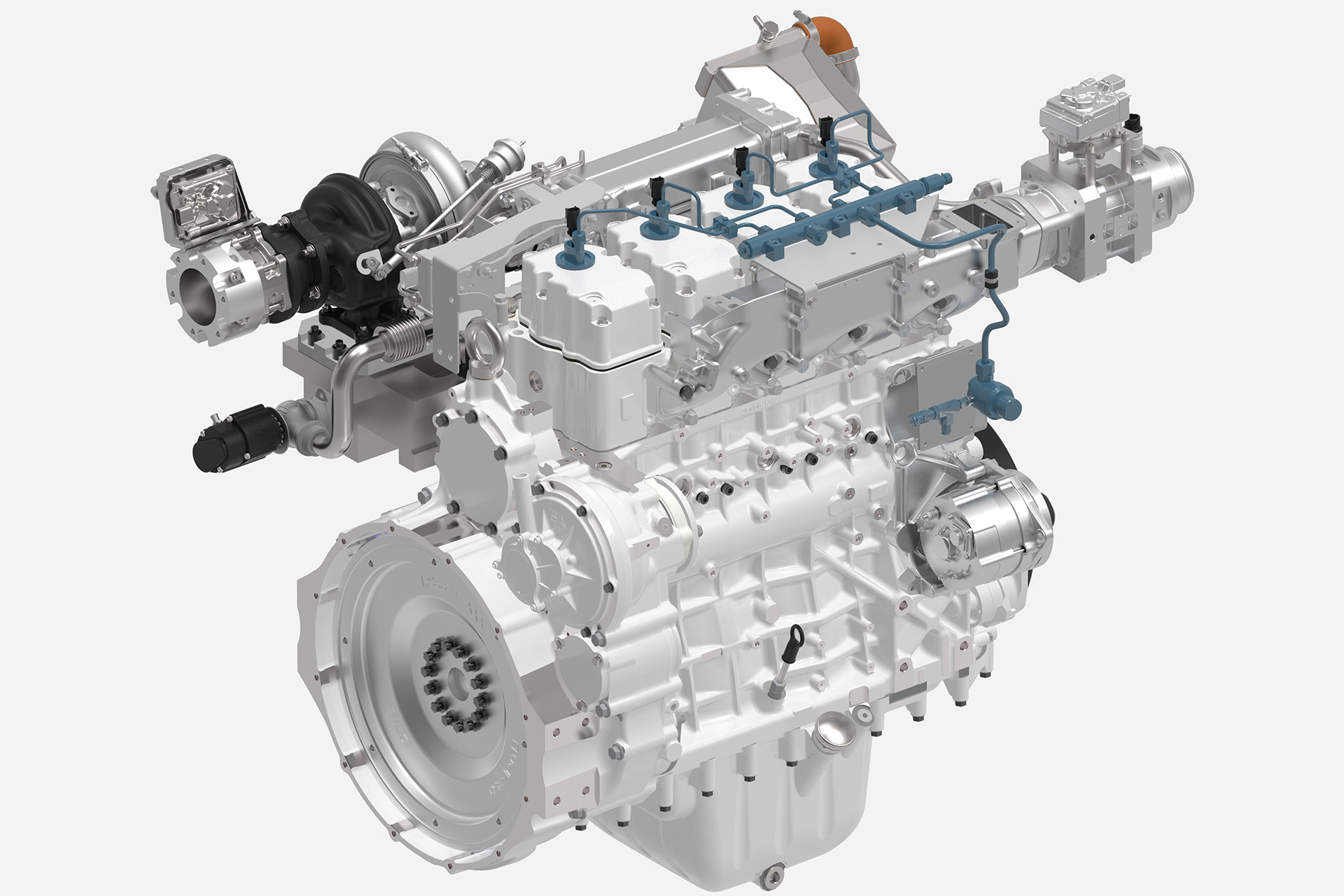

Hydrogen for a CO2-neutral future

With solutions for hydrogen combustion engines, Liebherr-Component Technologies AG unlocks the potential of this fuel as a carbon-neutral alternative for on- and off-highway applications. Thereby Liebherr pursues an open approach to technology for energy conversion. As an alternative climate-friendly combustion, Liebherr offers its own H2 direct injection for heavy-duty engines.

Liebherr Academy’s Gear Technology training goes digital

Liebherr is leading the way when it comes to digital learning. That’s why it launched its interactive online training course on gear technology. Participants can connect from anywhere to receive virtual training on the latest high-spec machines in Liebherr Gear Technology’s Machine Training Centre (MTC). Trainers use multiple cameras to explain the control system and functionalities of the machines. Thanks to the small training group sizes, each participant has plenty of opportunities to interact directly with the trainers.

Strong cargo handling partners

Three fully automated, rail-mounted gantry cranes (RMGs) are now in operation for the Carolina Connector Intermodal Terminal (CCX) in Rocky Mount (North Carolina/USA), where they support a state-of-the-art cargo handling system. The cabinless cranes are equipped with active front-end control and Liebherr Remote Operator Station (ROS). They can be controlled from the office and produce zero local emissions thanks to their electric drive system.

Trusted technology equipped for the future

Liebherr mobile cranes are driven by smart technologies. The heart of this crane control system is the original Liebherr Computer Control (LICCON) software and hardware. To cater to the customers’ ever increasing demands, specialists are working constantly to develop solutions even further. The third generation of the crane control system is meanwhile available on the market. The new LTM 1110-5.2 is the first Liebherr crane equipped with the LICCON3 control system, the centrepiece of which is its electronics system. In addition, the control also offers many features including new software, higher computing power and even better safety tools.