2 minutes | magazine 02/2019

Why is the LG 1750 lattice boom mobile crane so successful?

Liebherr will deliver the hundredth LG 1750 in mid-2020. Although there is a large number of crawler cranes in this lifting capacity class, crane contractors continue to choose the LG 1750 lattice boom mobile crane. We asked Klaus Huberle, General Manager Crawler Cranes, why this crane concept is so successful?

“Our customers generally look for the lowest cost crane concept – maximum lifting capacity, lowest possible transport costs and the minimum set-up times. Telescopic mobile cranes are best at meeting these requirements but the telescopic boom soon reaches its limits in terms of lifting capacity. Where the telescopic crane has to give up in performance terms, the LG concept comes into its own as the lattice boom delivers significantly higher lifting capacities due to its design. It can also be supplemented with a derrick system, which enables it to reach lifting capacities which are a multiple of those that a telescopic crane can achieve.

Klaus Huberle - General Manager Crawler Cranes at Liebherr

This has always been the case. For example, at the start of the 80s we built telescopic mobile cranes such as the LT 1300 with a lifting capacity of up to 300 tonnes on 8-axle chassis and lattice boom cranes that could lift up to 500 tonnes on the same chassis. Let’s just look at the 8-axle LG 1550, which is still popular today, and was launched a few years later. It shared its chassis with the LTM 1800.

The higher lifting capacity of the lattice boom crane comes at the price of greater transport volume and a longer set-up time for the boom, but the benefit of the LG crane with tyres remains. If, for example, we compare the LG 1750 with its counterpart, the LR 1750 crawler crane, the crawler crane chassis requires three transport units for the two crawler tracks and the centre section plus 95 tonnes of central ballast. The LG chassis, on the other hand, can be driven fully equipped to the site and requires very little set-up time.

The LG concept also delivers other benefits. In contrast to the crawler crane, the lattice boom mobile crane does not necessarily need a flat surface as it can be levelled using its four outriggers. The soil pressure from the supported crane is precisely defined and is generally lower than that of a comparable crawler crane. These are benefits on all sites, whether the crane is on a wind farm or performing heavy duty single hoists.

The special success of the LG 1750 is certainly also due to the fact that we did something new with this crane. We did not use an existing chassis from a telescopic crane, as we had done in the past, but designed a very specific new undercarriage. The special focus of this process was to enable the crane to travel between sites with some of its equipment at low cost. That is why it has particularly strong crane axles and tyres. This means that the LG 1750 can carry up to 40 tonnes per axle.

We must also mention the main benefit of a crawler crane at this point, however. It is very flexible to use as it can move with a full load on its hook. However, this requires a solid surface and the track must be adequately wide. These conditions are often not satisfied, however, particularly in wind farms. This is where the LG 1750 can show its strengths with its narrow chassis as the complete basic crane can be moved around the site. Its concept and its lifting capacity are unique. That is why, in addition to crawler cranes, Liebherr will continue to build LG cranes as a result of the benefits they offer.

All the crane types mentioned above have their own advantages. The good news for you is that we can always offer you the right crane with the perfect concept for your needs.”

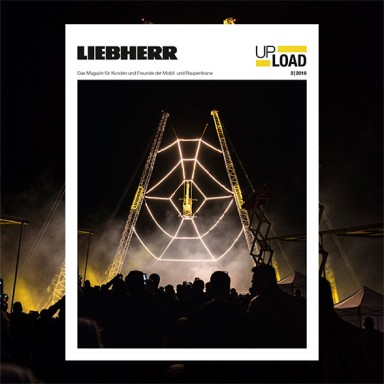

This article was published in the UpLoad magazine 02 | 2019.