HLC 295000: Swift and capable

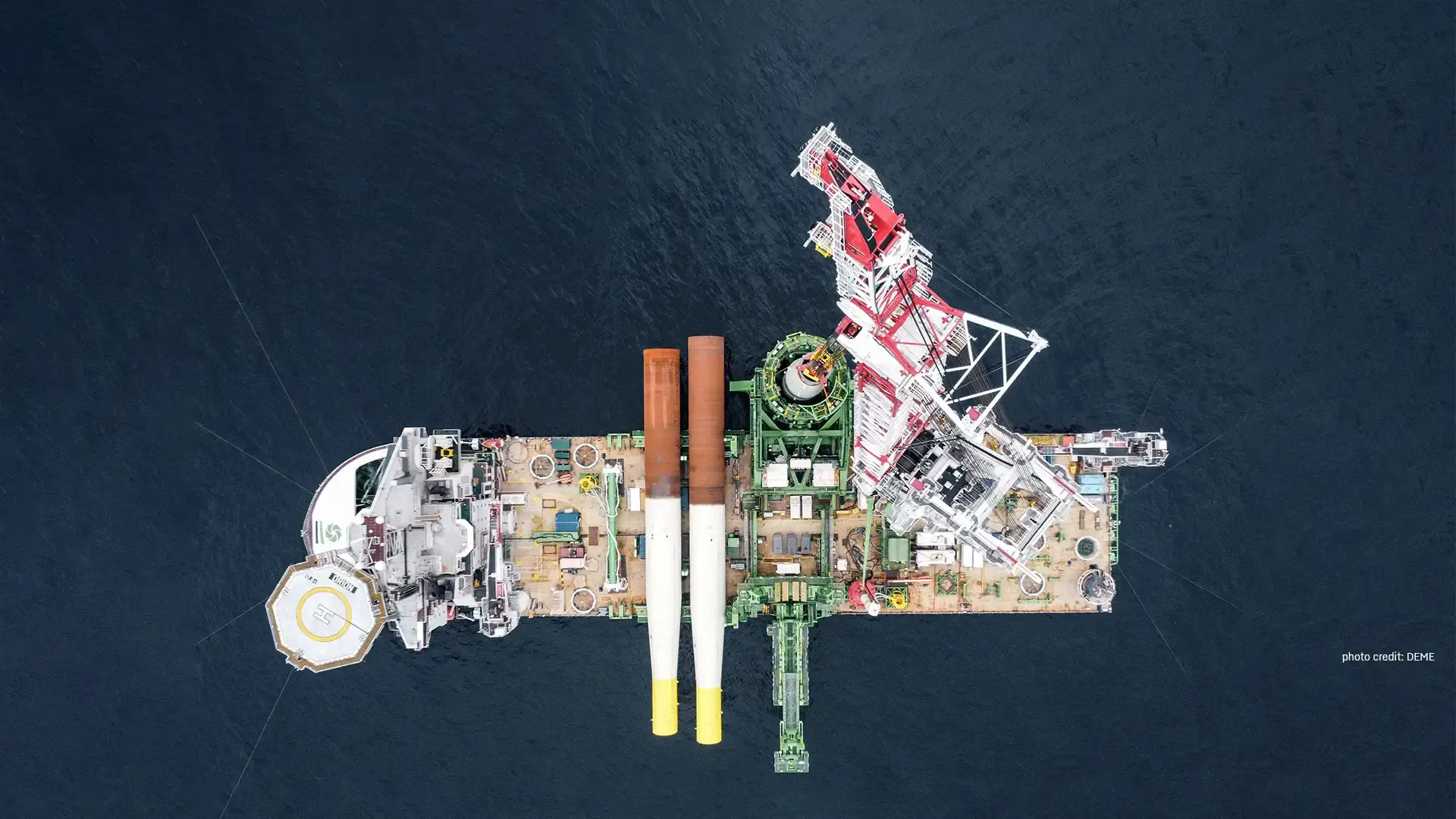

With the installation of the largest monopiles ever produced in Europe and the lifting of a substation platform, the heavy lift crane HLC 295000 has successfully completed its first two offshore missions in the wind energy sector. The jobs took place at the German wind farm Arcadis Ost 1 and the French wind farm Fécamp.

Rise of a giant

With a maximum lifting capacity of up to 5,000 tonnes and a maximum lifting height of 175 metres above deck, the HLC 295000 is the largest offshore crane Liebherr has ever manufactured. With this offshore crane and its modern technologies, the Orion is currently considered the most innovative vessel in the offshore wind industry. By dismantling the old and building up the new energy, the HLC series can promote the energy transition "at both ends of development" for a more sustainable future.

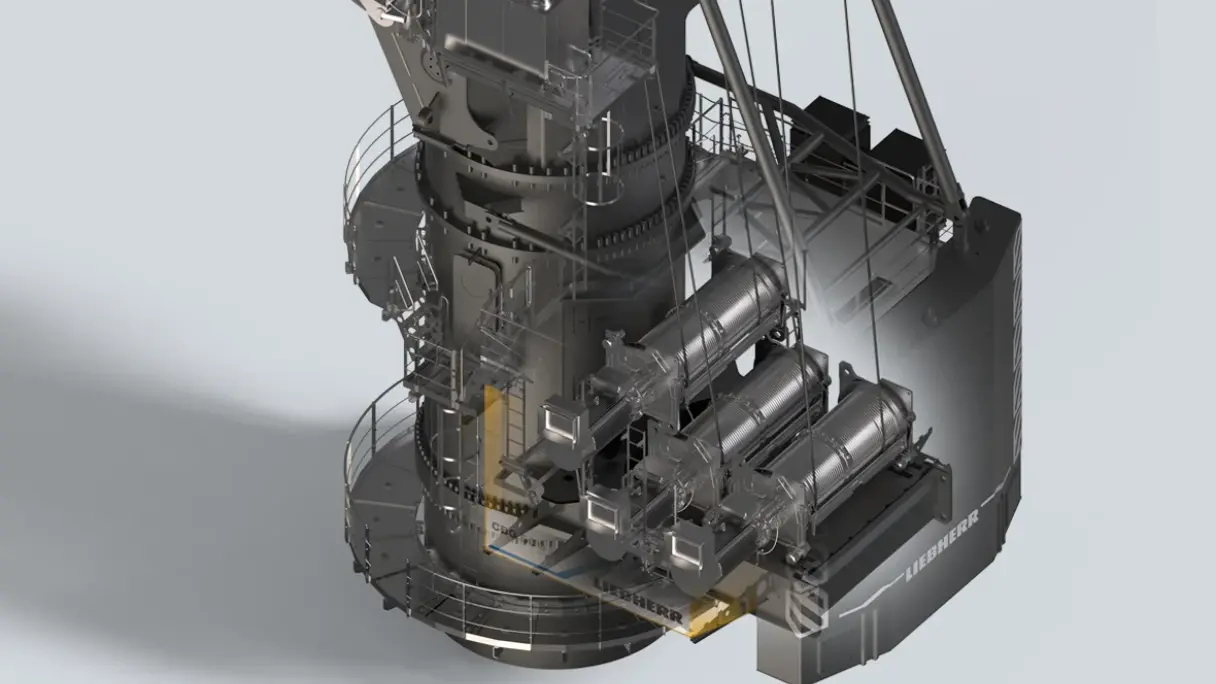

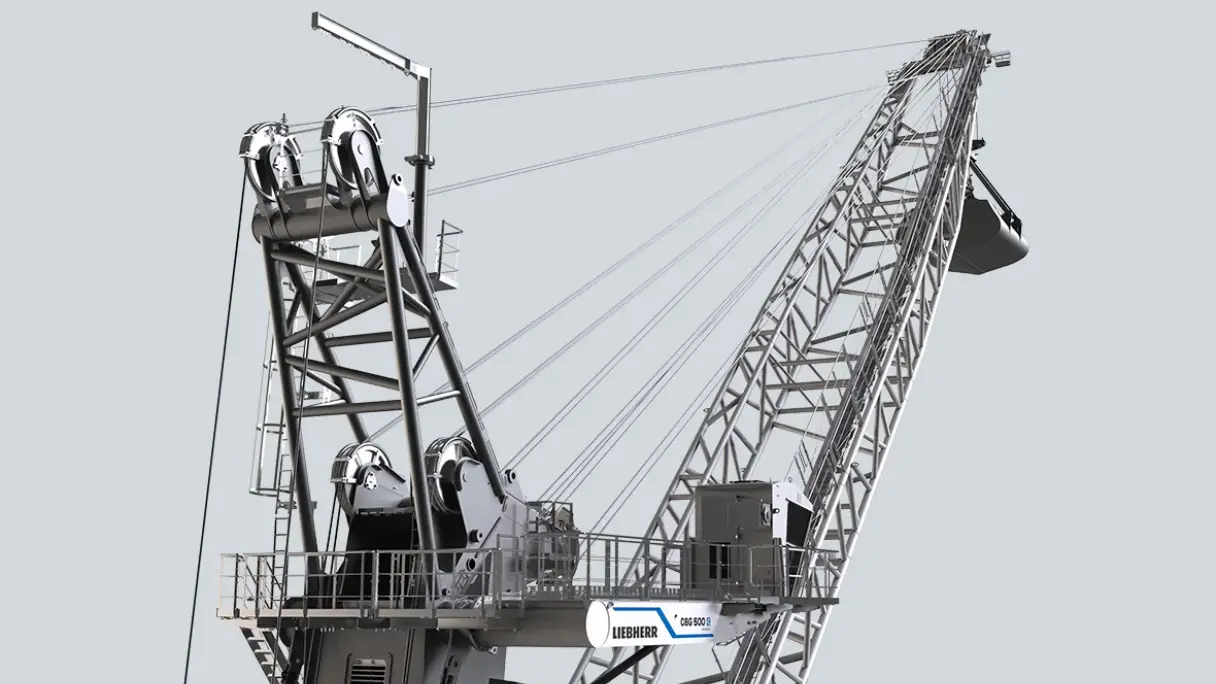

Designed for a new era of bulk handling

The all-electric transshipment crane CBG 500 E combines the market demands for a reliable crane with high handling capacities. Due to the electric drives, the available energy is used efficiently and the crane operates in an environmentally friendly manner. The CBG 500 E has a boom length of up to 50 metres and handles up to 2,000 tonnes per hour. In sheltered water the maximum load capacity in grab operation is 90 tonnes and in open water 65 tonnes.

The all-electric transshipment crane CBG 500 E

Sign up now!

Stay up to date with our latest product highlights, innovative technologies and exciting jobsites.

Three LHMs to Noatum terminals in Spain

Boarding the Heavy Load Carrier MERI in the morning hours of September 5, three Liebherr mobile harbour cranes were prepared for their journey to Spain. Three terminals operated by the Spanish company Noatum will benefit from the performance of the LHM 420 and LHM 550 models.

Liebherr Transform – Unleash the full potential

The demands on our daily businesses are continuously growing - increase volume, increase performance, widen scopes, or reduce emissions - the list is endless. That’s where Liebherr Transform comes in. With a wide range of state-of-the-art upgrades, retrofits, and overhauls, Liebherr Customer Service launched a solution to make your cranes stronger, faster, smarter, greener, and ultimately better.

31 youngsters start at Liebherr maritime cranes

With a bright smile and a great passion for technology, 31 new apprentices began their careers at the Liebherr plant in Rostock in September 2022. For most of them, these are the first steps in their professional lives. During this time, they are constantly supervised by experienced training and teaching staff.

Liebherr has always relied on competent and motivated employees as the key to success. The company meets the high performance and quality requirements with modern and qualified training of its own young employees in order to ensure that the demand for specialists can be met in the future.