More about the company

Liebherr careers

Next generation New standards

Next generation New standards

Powered for mining

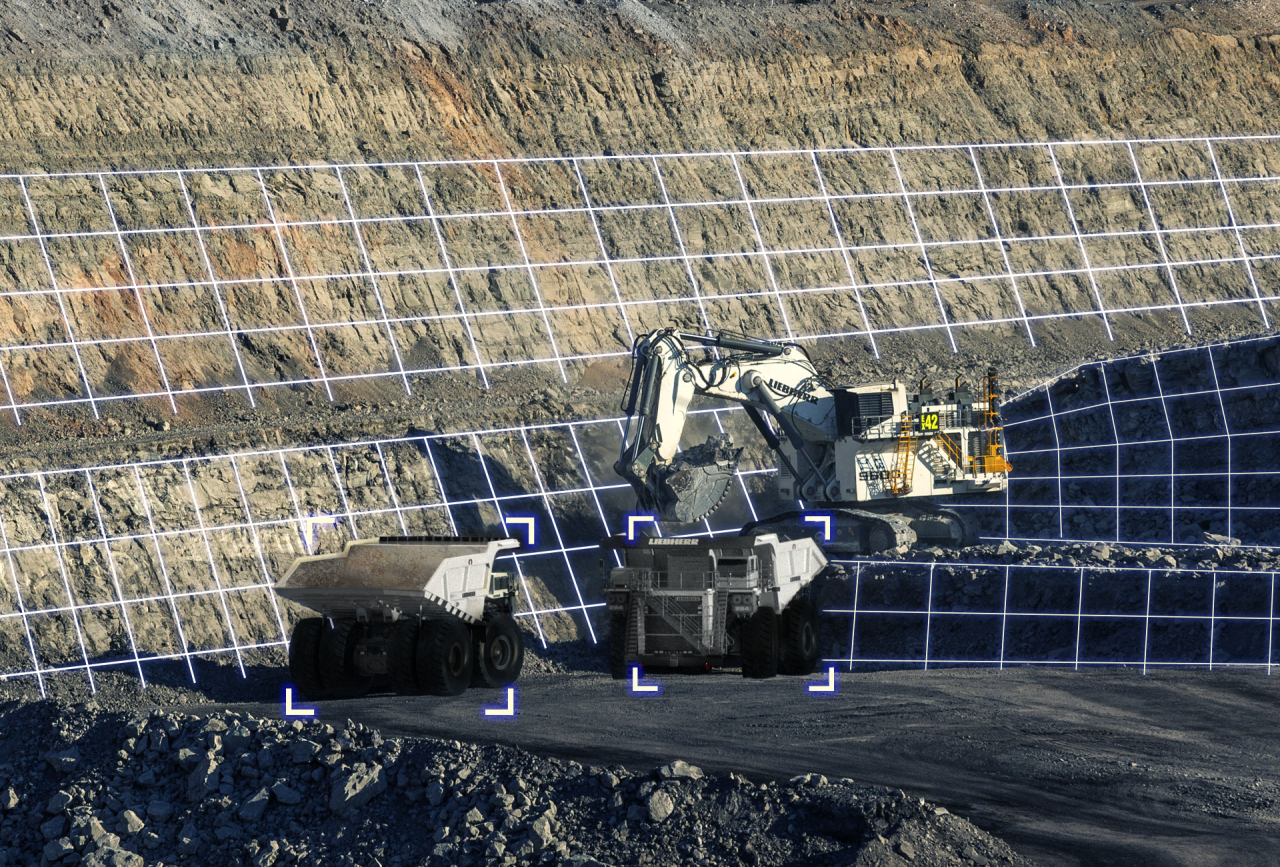

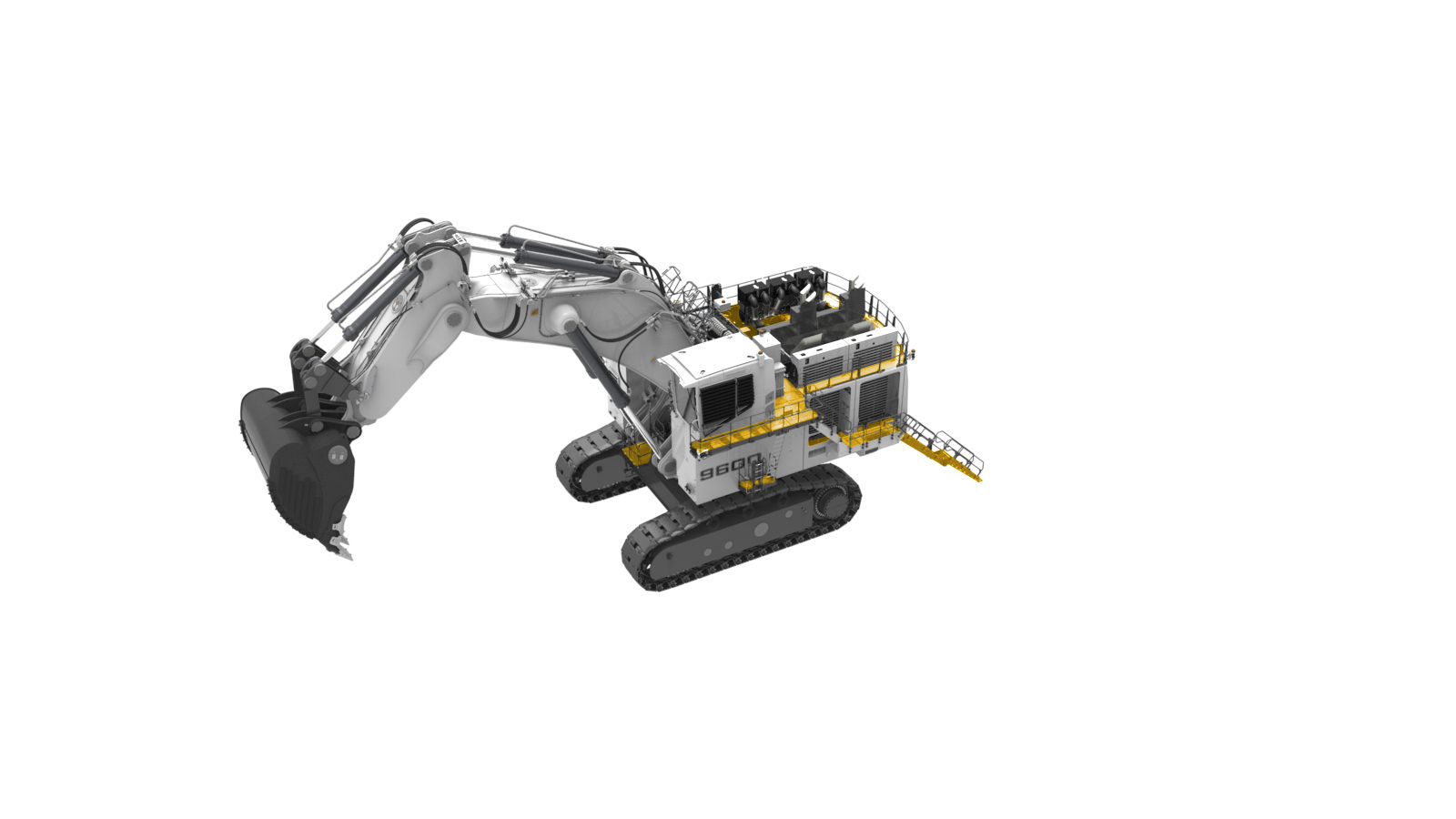

The new R 9600 has been developed with a customer centric approach to define new standards in the 600t mining class and it will mark the beginning of the new generation of Liebherr hydraulic mining excavators. Integrating latest technologies and brand new developments, its reliable undercarriage, high performance attachment, brand new cabin and on-board assistance systems enable the new Liebherr mining machine to achieve best productivity in any application. This means it can perform wherever the machine is operated.

This newest member of the Liebherr family is not only just powerful, robust and efficient, but also has been designed to provide easy maintenance and best serviceability. Build to perform, the new 600t Liebherr legacy continues with the R 9600.

New standards

Designed to be used in all applications globally, the R 9600 utilizes the latest quality control systems to ensure the best reliability and highest performance. After years of development, the new 600t excavator sets new standards in the open pit mining market.

Operating Weight

633 t

698 tons

Powertrain

2,500 / 2,400 kW

3,350 / 3,220 HP

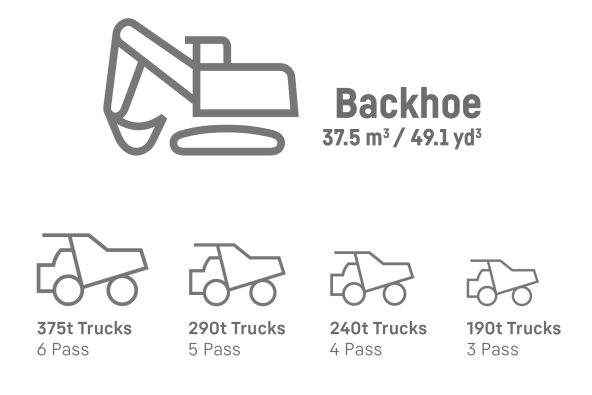

Bucket Capacity

37.5 m3

48.4 yd3

Breakout Force

1,730 kN

Digging Force

1,560 kN

Max. Oil Flow

8,520 l/min

2,248 gpm

A new performance benchmark

"The R 9600 sets a new benchmark in the Liebherr mining history and prepares our future product portfolio towards all the upcoming opportunities - Digitalization, Automation and Energy transition."

Michel Runser, Product Manager at Liebherr-Mining Equipment Colmar SAS

Ultimate comfort with ergonomic design

Liebherr Mining Assistance Systems

The Best Performance. Easy.

Available today inside the R 9600, the Liebherr Assistance Systems are advanced onboard applications designed to support operators to become more efficient through analytics and actionable insights from live data. It will help the operator to get optimal productivity and efficiency by providing realtime operational datas.

Truck Loading Assistant

Assists the operator to obtain target truck payloads.

- Measures instantaneously the bucket payload

- Provides real-time information to the operator

- Strategizes the number of passes required

- Computes the best truck loading strategy

- Automatic truck recognition (optional)

Customer advantages:

- 99% measurement accuracy

- Increase in operational and instanteneous productivity and increased truck fill factors

Performance Monitoring Assistant

Measures and analyzes the overall performance.

Using KPIs, histograms and time-related charts

- Production indicators

- Loading indicators

- Time distribution

- Powertrain energy efficiency

Customer advantages:

- Understand operational performance

- Make operational decisions based on KPIs

Application Severity Assistant

Quantifies application, reports severity indicators and provides an Overall Application Severity score (TRC).

KPIs to indicate and display the application as sensed by the machine.

- Underfoot and digging conditions

- Abrasiveness and travel ratio

- Engine load factor and temperature variation

- Machine inclination, loading, etc.

Customer advantages:

- Understand your application

- Graphical interface

Operational Conformance Assistant

Detects and counts events to improve operator effectiveness.

Several filtering criterias to identify specific events.

- Swinging into digging face

- Digging with swing brake activated

- Turning the machine with the attachment

- Bucket hitting track pads, etc.

Customer advantages:

- Increase machine operational safety, machine lifetime & availability

- Helps understanding reasons for downtimes or delays

Bucket Filling Assistant

First automation product of the Liebherr hydraulic excavator portfolio, this combination of two innovative engineering developments is an optional feature that allows easier bucket filling and consistent bucket fill factor, especially in blocky or hard digging conditions. As a result overall productivity improves while operator's fatigue decreases.

Anti-Stalling Function: Prevents the bucket from being stalled during the digging phase.

Semi-Automatic Bucket Filling Function: Allows the operator to realize the bucket filling process automatically.

- Less operator fatigue

- Increased productivity

- Better fill-factor

- Continuous efficiency

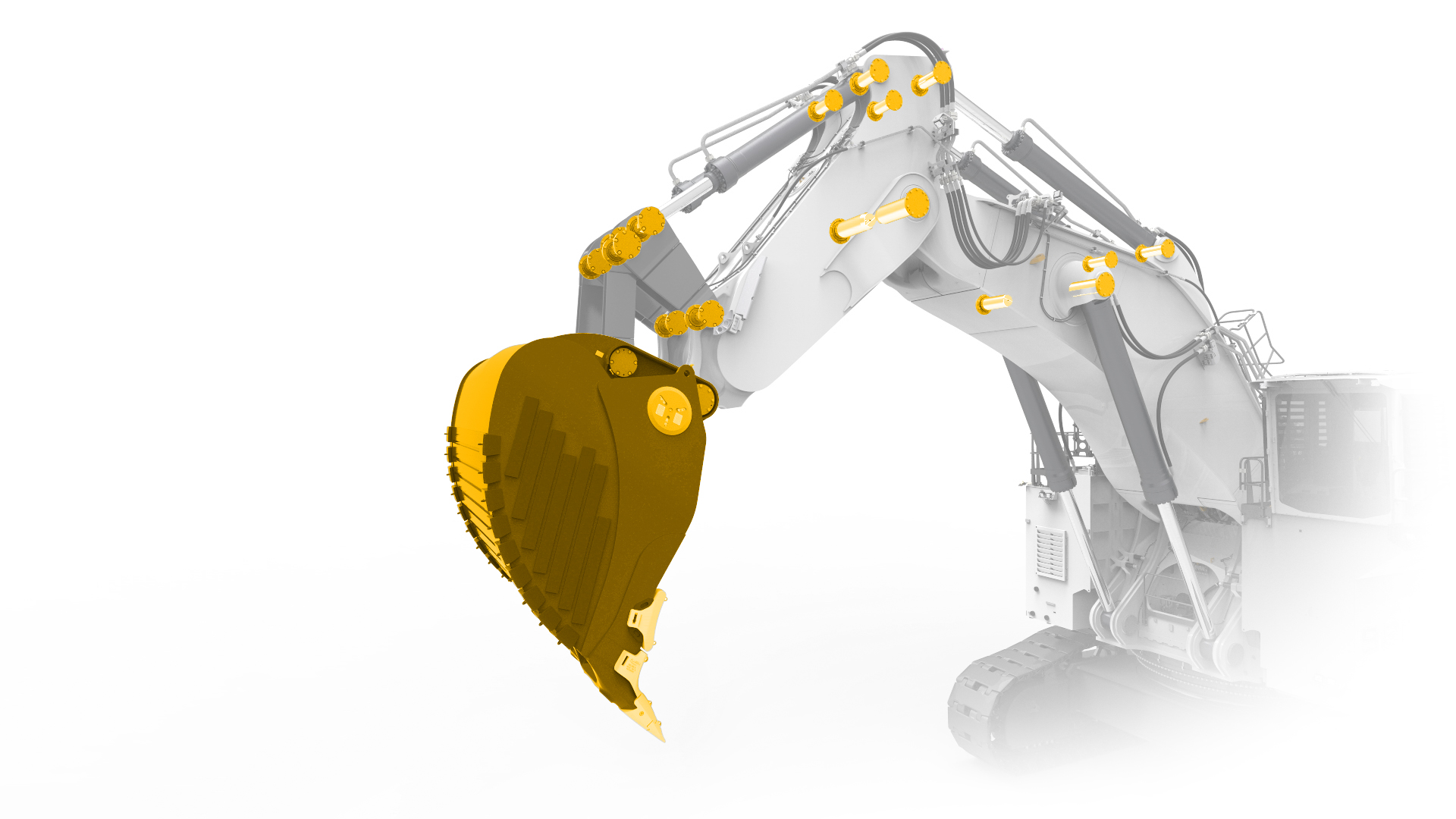

High Performance Execution

Thanks to its innovative attachment solution improving cost per tonne, maximizing machine productivity and improving component lifetime, Liebherr redefines performance standards in the 600t class.

- Use of smart components design to reduce weight, improve bucket protection and increase digging forces:

When mining applications become demanding, Liebherr attachment solutions provide best in class fatigue resistance and productivity. Using hollow pins and aluminium covers on all attachment points, Liebherr engineers are able to install bigger buckets, which enable higher performances.

Maximized payload

Designed for best force distribution, the tailored attachment design delivers high digging and lifting forces, which ensures maximum payload during each cycle. But by optimizing the bucket shape and reducing the bearing block, Liebherr has engineered a patented bucket design to improve productivity without impacting cycle time or fuel consumption.

The EVO bucket allows the operator to take advantage of each pass and therefore increase productivity.

- Increased Productivity up to +15%

- Better Loading Capacity +5%

- Weight Optimization -10%

- Reduced Maintenance

Optimized cost per ton

- Simplified design

- Less internal reinforcement plates

- Reduced stress levels and better stress distribution

- Weight optimized hydraulic cylinders

- Shift lever with integrated greasing system

- Protected grease manifolds

Built to outperform all competitors in the 600t class, Liebherr offers the best durability by creating a brand new machine and components to deliver state-of-the-art capabilities and reliability.

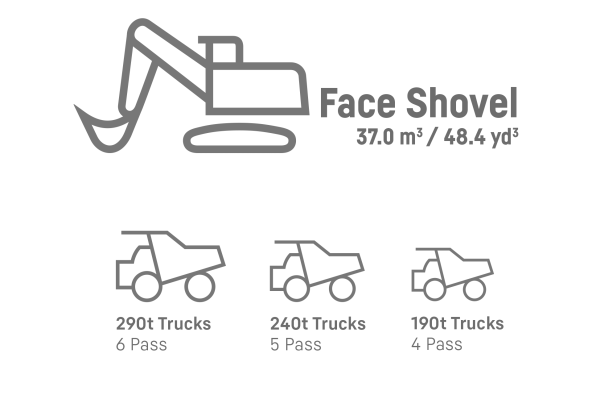

Shovel truck match

Liebherr Power Efficiency

Use only the power and the hydraulic flow you require

Specific engine and hydraulic management, drastically reducing fuel consumption.

- Maximize hydraulic efficiency

- Reduce hydraulic throttling and load profile of the engine for increased component lifetime

Safety & Serviceability

The R 9600 provides safe machine accessibility and wide catwalks for inspection.

The uppercarriage has been designed for easier maintenance and quicker service. The central service area provides the staff accessibility to all features, which reduces potential downtimes. Refill and drain points of the R 9600 are well accessible from the ground with fast couplings and depressuraized valves.

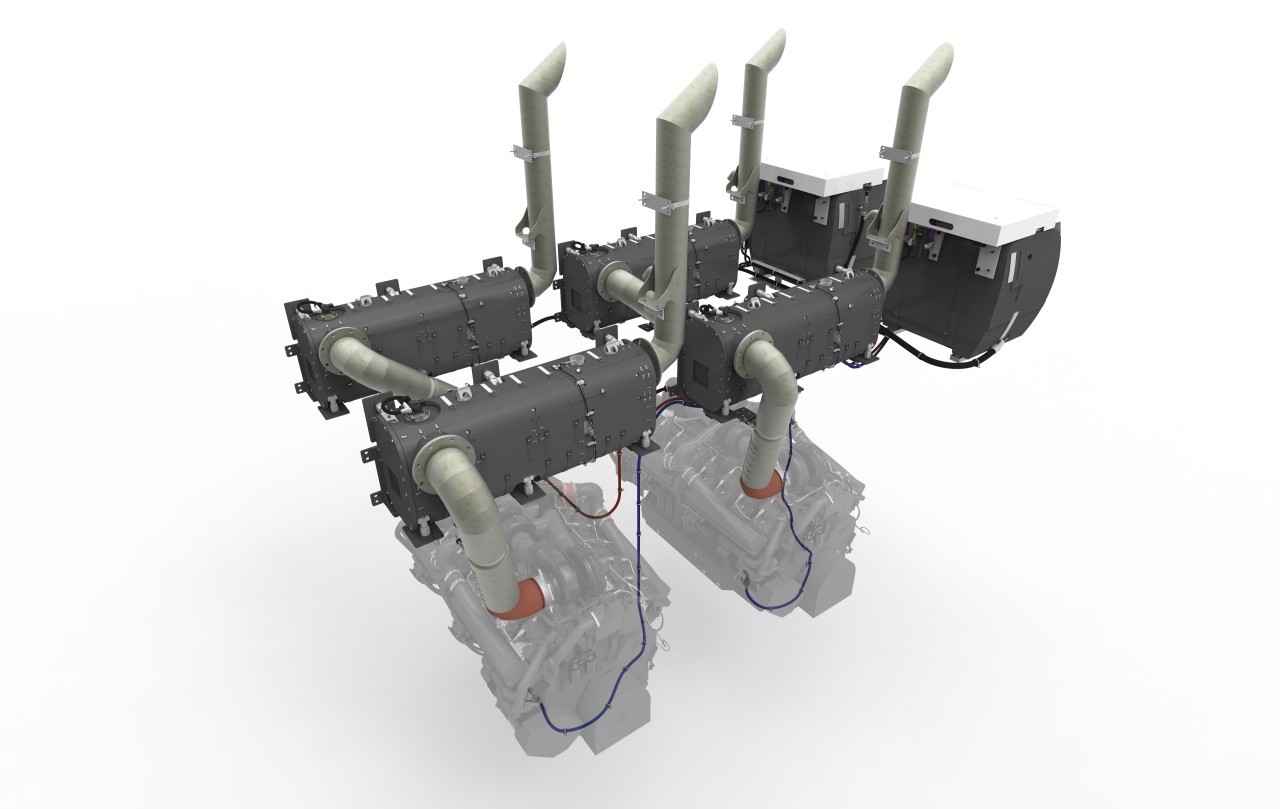

Diverse powertrain offering

The R 9600 can be fitted with different powertrain options:

- Diesel: 2x QSK50 Cummins - 2,500 kW / 3,350 HP

- Diesel: 2x D9812 Liebherr – 2,700 kW / 3,620 HP

- Electric: 2,400 kW / 3,220 HP

Diesel drive: US EPA Tier 4f / EU Stage V

Using Selective Catalytic Reduction system to comply with latest emission regulations the R 9600 combines flexibility and productivity to meet customer expectations without compromising productivity and impact on the environment.

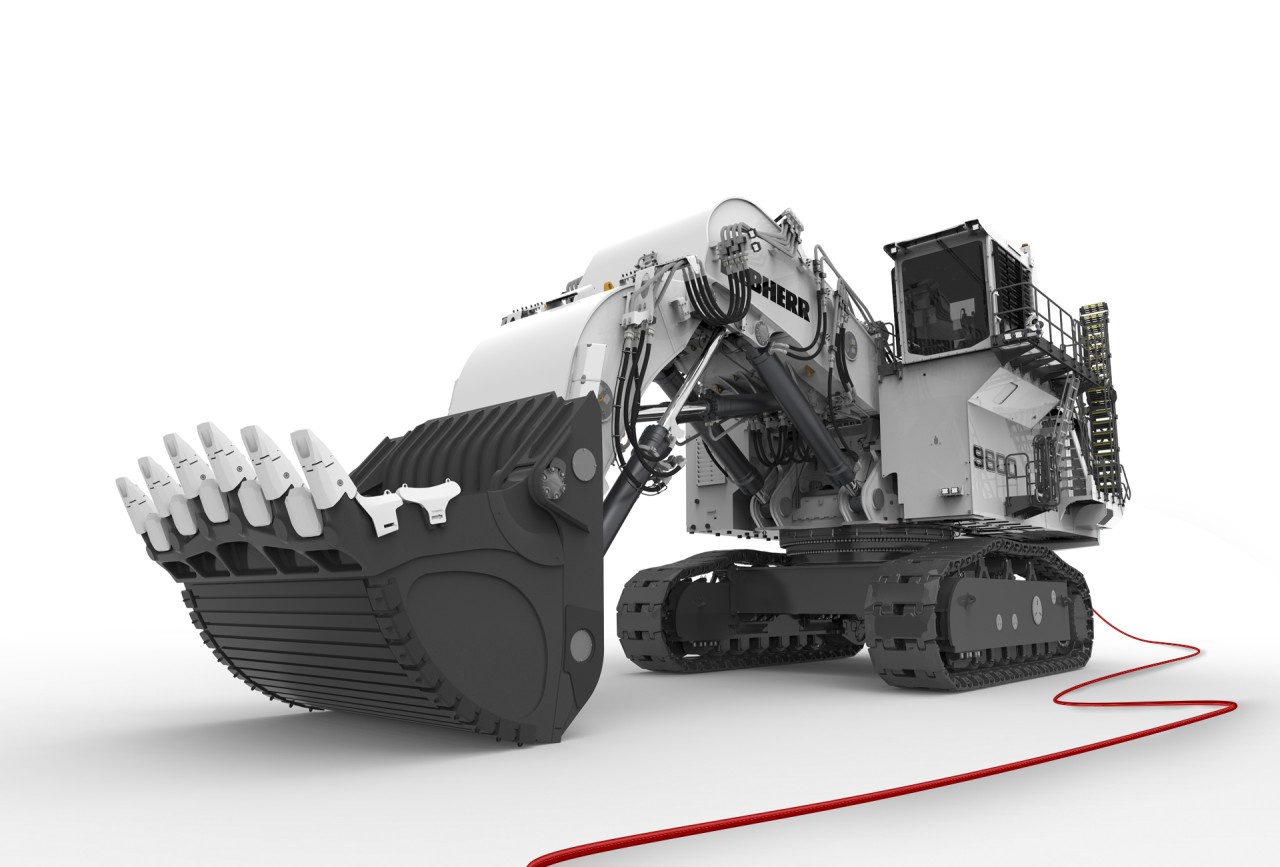

Electric drive

The electric drive system is an efficient alternative to diesel engines allowing less vibrations, lower maintenance costs and less noise pollutions. With high motor efficiency, electric drive option gives maximum performance even in cold climate conditions.

- No gas emissions on job site

- Lower maintenance costs

- Multiple voltage on request

This YouTube video is provided by Google*. If you load the video, your data - including your IP address - is transmitted to Google and may be stored and processed by Google inter alia in the USA. We have no influence over further data processing by Google.By clicking on "Accept", you consent to the transmission of data to Google for this video in accordance with Art. 6 (1) (a) GDPR and at the same time explicitly consent to the transfer of data to the USA in accordance with Art. 49 (1) (a) GDPR. If you no longer wish to consent to each YouTube video individually in the future and wish to be able to load the videos without this blocker, you can also select "Always accept YouTube videos" and thereby consent to the associated data transmissions and transfers to Google and to the USA for all other YouTube videos which you open on our website in the future. Please note that, in the opinion of the European Court of Justice, there does not currently exist an adequate level of data protection in line with EU standards in the USA, and at present we cannot provide appropriate safeguards to protect your data and offset this shortcoming.Possible risks to you of data transfer to the USA are that access by state authorities cannot be excluded and that your data could be processed for reasons of national security, law enforcement or for other purposes in the public interest of the USA, possibly without you being informed separately and without enforceable rights and effective legal remedies being available to you.You can withdraw consent that you have given at any time with future effect via the settings. For further information, please see our Data Protection Declaration and Google's Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA

Product Video

The successor to the thoroughly proven and iconic R 996B is based on the successful R 9800 and fitted with the most advanced Liebherr Mining technologies including Assistance Systems and Semi-Automated functions.

Watch our product video here!

Find a dealer near you!

This map material is provided by Google*. If you load the Google Map, your data - including your IP address - is transmitted to Google and may be stored and processed by Google inter alia in the USA. We have no influence over further data processing by Google.By clicking on "Accept", you consent to the transmission of data to Google for this Google Map in accordance with Art. 6 (1) (a) GDPR and at the same time explicitly consent to the transfer of data to the USA in accordance with Art. 49 (1) (a) GDPR. If you no longer wish to consent to each Google Map individually in the future and wish to be able to load the maps without this blocker, you can also select "Always accept Google Maps" and thereby consent to the associated data transmissions and transfers to Google and to the USA for all other Google Maps which you open on our website in the future. Please note that, in the opinion of the European Court of Justice, there does not currently exist an adequate level of data protection in line with EU standards in the USA, and at present we cannot provide appropriate safeguards to protect your data and offset this shortcoming.Possible risks to you of data transfer to the USA are that access by state authorities cannot be excluded and that your data could be processed for reasons of national security, law enforcement or for other purposes in the public interest of the USA, possibly without you being informed separately and without enforceable rights and effective legal remedies being available to you.You can withdraw consent that you have given at any time with future effect via the settings. For further information, please see our Data Protection Declaration and Google's Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA

All comparisons and claims of performance are made with respect to the prior Liebherr model unless specifically stated.