Knowing beforehand how it will work in production

The virtual commissioning of a palletizing cell with automatic loading of a gear skiving machine significantly shortened the project duration at a transmission manufacturer. The preliminary simulation via a “digital twin” helped save time and costs during the actual commissioning and ensured planning reliability for the start of production.

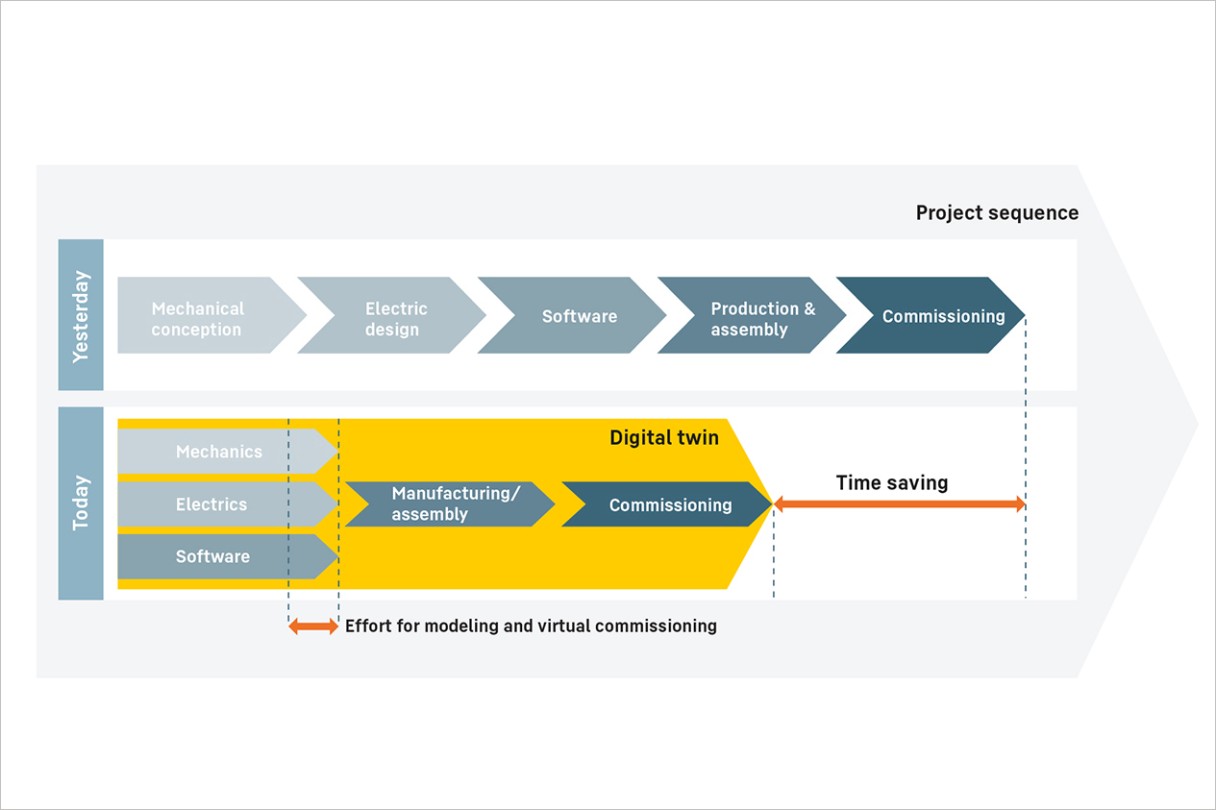

During virtual commissioning, the entire plant is simulated with the help of a digital twin. The interaction of mechanics, electronics and software can be thoroughly tested and optimized using CAD planning data. Any errors and faults can be identified at an early stage before unexpected problems arise during actual commissioning, particularly in the case of complex plants and systems or new developments. On site, i.e. exactly where deadline pressure often prevails, the time required for assembly and commissioning is significantly reduced.

Significant time savings thanks to the simulation and digital twin

Palletizing cell with robot loading by Liebherr

This case involved a highly versatile palletizing cell with robot loading of a Liebherr-Verzahntechnik GmbH gear skiving machine. This is being implemented by an automotive supplier that manufactures mobility systems for passenger cars, commercial vehicles and industrial technology. The robot cell automatically feeds the gear skiving machine with different workpieces. It can load and unload raw and finished parts, mixed or sorted, according to type and detect various basket types and heights, which are arranged in three feeder chutes. Despite its high level of versatility, the stacking cell is very easy to set up and operate.

Simulating instead of trying blindly – with the digital twin

Liebherr simulated the palletizing system in the form of a kinematic model using existing CAD data, linked it to the PLC control technology and tested all parameters and motion sequences of the system, including malfunction and collision scenarios. Developmental steps, which usually take place sequentially in classical engineering, now run in parallel. This “simultaneous engineering” significantly speeds up and simplifies plant development and commissioning. The continuous feedback provided by the digital twin identifies weak points and optimization potential as early as the development phase, saving time and minimizing risks for the start of production.

Time savings, cost reduction and risk minimization

The benefits of virtual commissioning are especially visible to the customer: commissioning time is significantly shortened, costs are reduced and production can start more quickly. Thanks to the tried and true automation software, the interaction between the palletizing cell and the machine tool works smoothly from the very start. “Another benefit is that virtual commissioning is not only possible in conjunction with Liebherr machines, but also with machines or systems from other manufacturers,” states David Bodenmiller, Automation Development Engineer at Liebherr-Verzahntechnik GmbH.

Of particular interest for complex plants

Production process stability and the availability of machines also improve during the course of operation. Modifications or system expansions (as well as any malfunctions) can be simulated on the digital twin, which simplifies remote support. “Particularly in complex plants, virtual commissioning makes it easier to plan and gives the customer a high degree of security. As a special plant manufacturer, we will definitely continue along this route,” says Jürgen Groß, Head of Sales for Automation Systems at Liebherr-Verzahntechnik GmbH.