8 minutes reading time

The perfect lift

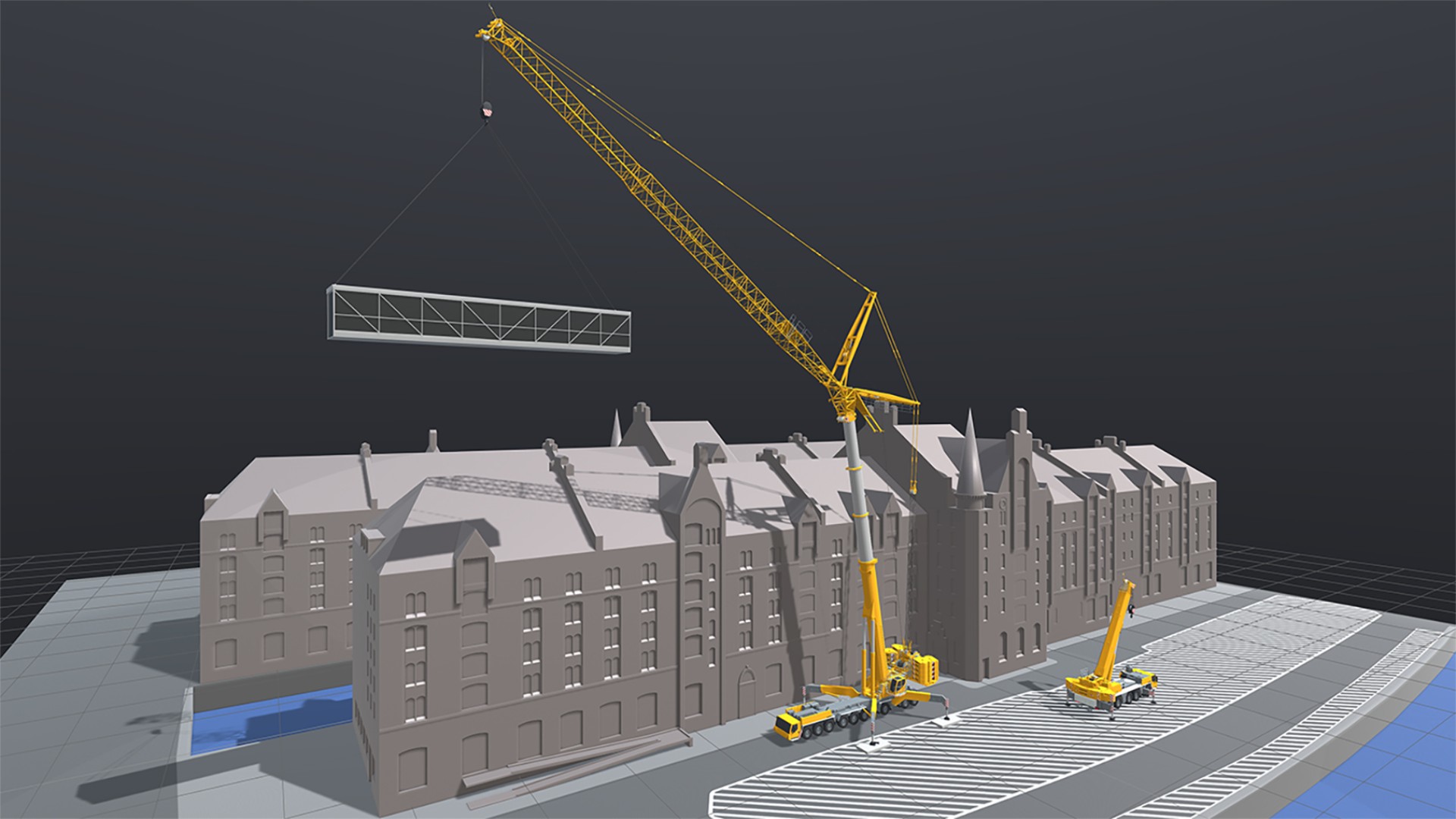

Which crane is best suited for which task on which construction site? Answers, in up to 1.6 million individual configurations, are provided by Liebherr's 3D planning software: Crane Planner 2.0. The collaboration between Liebherr engineers and 3D experts turns working with highly sophisticated technology and its unlimited potential applications into child's play.

From computer game to building site

Climbing into a crane and lifting a heavy load – that's something he has always wanted to do. So far, however, Sebastian Knapp has never had the opportunity to do it. Nevertheless, the 31-year-old can by all means be described as a recognised crane expert. Since 2015, he has constructed countless cranes, moved them around construction sites of every conceivable type and successfully performed an endless number of lifts, often of record-breaking proportions. Sebastian Knapp is a software developer at weltenbauer. Software Entwicklung GmbH in Wiesbaden. Since 2015, he has worked primarily on Liebherr's Crane Planner, the latest version of which, Crane Planner 2.0, has now been launched.

"The program uses the latest 3D real-time computer graphics to help users find the right crane for the right lift and to configure it directly on the construction site so that it will work optimally," explains the software developer. Once configuration is complete, the Crane Planner can also create reports containing the relevant machine data and technical drawings, as well as the comments and notes made during setup.

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).

Crane Planner began its journey in 2015

Sebastian Knapp's counterpart is based around 450 kilometres further south, in the Austrian state of Vorarlberg. Christoph Mai is Product Manager Crane Planner at Liebherr-Werk Nenzing GmbH, which develops, produces and markets principally multi-purpose crawler cranes, as well as duty cycle crawler cranes and piling and drilling rigs for deep foundation work. As Liebherr is a system supplier, its portfolio includes not only machines such as these, but also a variety of services and service solutions for simplifying processes on the construction site. Since 2015, these tools have included Crane Planner, the lift-planning tool developed by Liebherr with weltenbauer. Christoph Mai has helped to shape and manage its development from the outset. "We aim to give our customers, who are primarily from the crane rental sector, a planning tool that is fully tailored to their needs and requirements," he says. To that end, Crane Planner 2.0, with over 30 types of cranes, offers them a staggering 1.6 million configuration options.

The secret is the unique combination of an attractive, three-dimensional user interface and the precise machine data of the load moment limiter (LML / LICCON). All the data displayed is determined using precisely the same calculation logic as the live data of real mobile and crawler cranes.

_w592.png)

"Crane Planner 2.0 determines important indicators such as ground pressures, ground reaction force, loads and centres of gravity. A new calculation is performed for each change of configuration, load or geometry," explains Christoph Mai. "We can thus provide our customers with a generic module that contains all setup and operating parameters." And that also makes them fit for the age of Building Information Modelling (BIM). In this comprehensive process for creating and managing information for a construction object, BIM integrates structured, multidisciplinary data to create a digital representation of an asset throughout its entire life cycle - from planning and design to construction and operation.

Not only does this sound complex, it is. To ensure the user doesn't need to be an engineering scholar, Liebherr has been working with the digital experts from weltenbauer. since the early days of Crane Planner. The software developers from Wiesbaden incorporate experience of computer games, 3D industry applications and digital solutions for different platforms and environments. "We create software for mobile devices, desktop systems, next-generation consoles and mixed reality environments, and know how to build virtual worlds," explains Christian Rathemacher. The 38-year-old has been on the management board of weltenbauer. since 2011 and has been part of the Crane Planner project since its very beginnings. He explains that they started with the Construction Simulator from the computer games field. "Then, together with Liebherr, we became more and more involved in Crane Planner. It is incredibly exciting to see how far you can take a machine to its limits in the digital realm, and in doing so tap its full potential. And in total safety."

Did you know?

30 Liebherr mobile cranes, crawler cranes and duty cycle crawler cranes are currently included in Crane Planner.

A computer game - the Construction Simulator - laid the foundation for Crane Planner.

The Engineering Matters Podcast episode "How to plan a lift" gives exciting insights into working with Crane Planner.

The Crane Planner 2.0 tutorials are available online for you to explore.

Students also learn with Crane Planner: more about this in the interview with Frank Will from the TU Dresden at the end of this story.

Complexity made child's play

Crane Planner 2.0 makes planning a lift look like child's play. With just a few clicks of the mouse, an impressive crane, which can be moved in any direction and integrated into a construction site environment of your own design, appears on the screen. All the actions that it performs are displayed in detail, together with design and load data – all with the utmost precision.

"We are merging the technical world and the world of games," says Sebastian Knapp. "Crane Planner is designed not only to provide precise information but also to be fun to use for planning a crane and trying out its operating ranges on specific construction sites."

Typical areas of application include demanding lifts in urban areas. For example, in Hamburg's Speicherstadt warehouse district. Hanseatic merchants and town planners in the Middle Ages could not have foreseen the use of large mobile cranes for building work. As a result, today there is little room to manoeuvre. To be able to deploy a 300-tonne crane here efficiently, safely and without collisions, planning rapidly becomes a precision exercise. "In Crane Planner 2.0, we can collate all the data about the crane and its surroundings for such cases, and the system issues direct warnings with red collision markers if things might get tricky at any point. This makes it possible to achieve the perfect lift safely in this very specific and challenging environment," says Christoph Mai proudly.

Finding the happy medium

The 3D representations are optimised to make them easy to use. As much information as necessary, as little as possible, so as to make the overall picture clear and intuitive to manage. At the same time, however, the information must also be sufficiently precise that no safety-related information is lost. "Our aim is to find a happy medium between reduced and essentially important data," explains Sebastian Knapp. Safety always has top priority. As a matter of principle, the weltenbauer. software developers work according to the dual control principle at every development stage, so that no safety-related detail is overlooked. The Liebherr experts then take the resulting work and painstakingly check all the machine data. "With this integrated, iterative approach, we are taking the digital configuration of crawler and mobile cranes, as well as duty cycle crawler cranes, to a whole new level," enthuses Christoph Mai. The game and 3D computer graphics developers in Wiesbaden share this enthusiasm unconditionally. "We currently work on the basis of two updates a year for Crane Planner," says Christian Rathemacher. "However, we are able and keen to respond to new customer requirements even faster and at shorter notice so that the cranes and their users on the construction sites of this world are able to utilize their full potential at all times."

Software developer Sebastian Knapp is happy to be involved: "Moving virtually around a planned future construction site and being able to dimension and position your machines optimally is a great way of working. And it goes on and on with constantly new challenges and opportunities – a never-ending story." Sebastian Knapp's eyes light up as he says this – that's why he doesn't ever need to climb into a crane himself.

Crane planner goes university: the interview

An interview with Professor Frank Will, Chair of Construction Machinery in the Faculty of Mechanical Engineering at Dresden University of Technology.

Professor Will, how did you and your department become aware of Crane Planner?

About two years ago, Christoph Mai from the Liebherr plant in Nenzing gave a talk in which he presented the idea of Crane Planner at a specialist conference on construction machinery technology, which was organised by my faculty in Dresden. It was very interesting, so we pursued the idea further in discussions with Mr. Mai.

How do you rate the three-dimensional planning tool?

The 360-degree view makes it easy to visualise the realistic planned use of a crane. The environment, i.e. the buildings, other machinery, personnel access areas etc., for each use case can be displayed much more clearly and understandably in 3D. This makes planning easier, as well as any training needed for specific deployment scenarios. For example, testing out movement paths, avoiding obstacles or recognizing critical situations. It is also much easier to achieve intuitive operation with a 3D tool than with a 2D version.

How do you rate Crane Planner 2.0's playful approach to crane physics?

Its three-dimensional, realistic representation and the "playful" way in which it is used have many advantages: they make it easier to understand the structure and functioning of crane systems. The physical relationships also become intuitively clear, for example, through direct display of the ground pressures when the jib is moved. In addition, you can use Crane Planner to test out situations which are better not tested out in real life. For example, operation at the limits of its range, where the user is given direct visual feedback. And last but not least, the "fun factor" makes people engage more intensively with the subject – more than they "have to", with a corresponding gain in understanding.

How do you yourself use the Crane Planner in your department?

We are currently planning a student research project which will examine the possibilities and limitations of IT tools for planning the use of mobile and tower cranes – Crane Planner will be the main tool looked at here. In addition, here in Dresden we intend to use the tool in the "Construction machinery technology" lecture, which is attended by 60 to 80 mechanical engineering and mechatronics students every year, to explain the following points in a section of the lecture:

- The structure, components and functioning of various types of crane

- What situations and questions have to be borne in mind when planning the deployment of a crane (setup areas, ground conditions, transport routes, assembly/disassembly, work areas, collisions)?

- What is the key information (added value) an IT tool has to offer?

- What are the advantages (and, where applicable, disadvantages) of tool-assisted planning compared to previous methods?