Reman components: ready for a second life

As soon as a component needs to be replaced, you have a decision to make: new OR reconditioned?

We want to keep your downtime to a minimum and your profits to a maximum – our Reman Programme keeps your machines moving.

With our ever expanding Reman Programme we offer you reconditioned components that are as good as new in terms of performance and reliability. At the same time, we’re kinder on your wallet and the environment – a win-win situation for everyone.

01/04

01/04

The 3 stages of the Reman programme

No matter what type of maintenance you perform on your Liebherr machine - Liebherr offers you the most economical solution for all requirements.

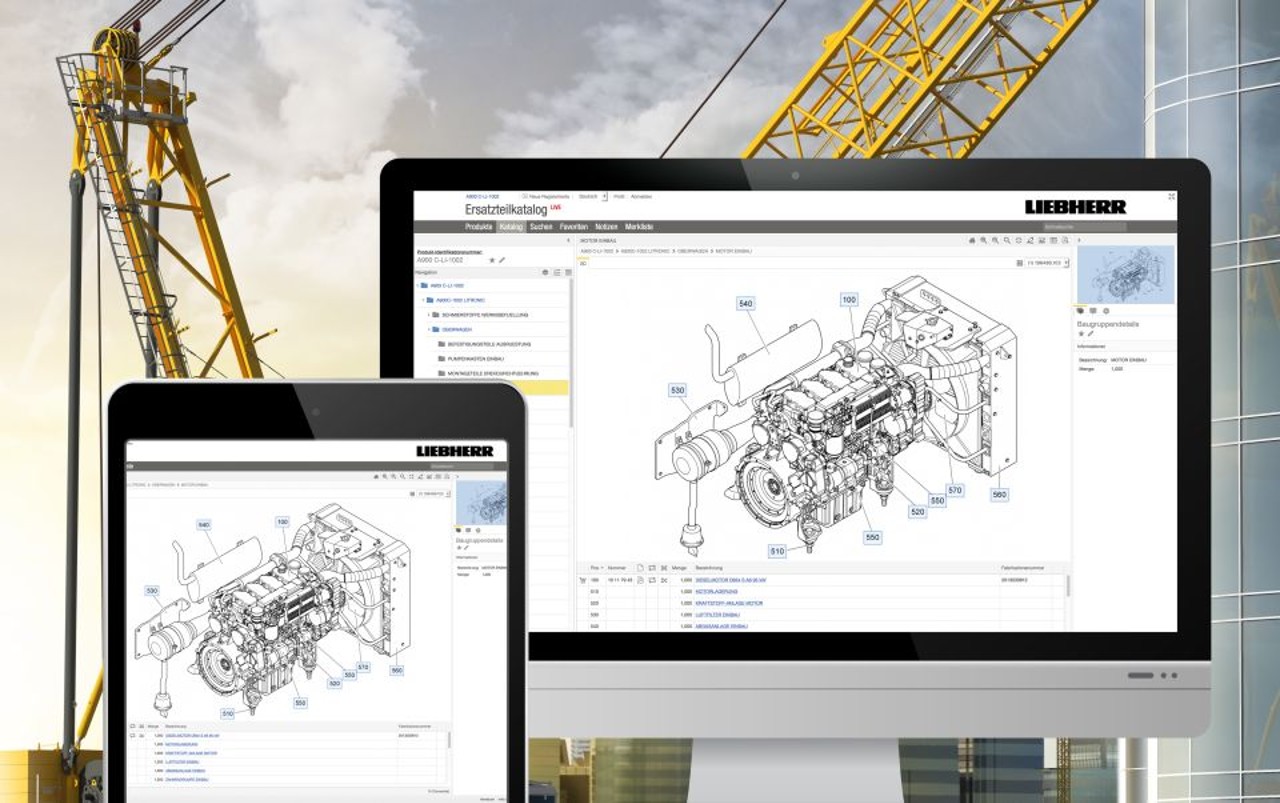

MyLiebherr

Find and order replacement components easily

The portfolio of replacement components is constantly being expanded. Check right away to see if your required part is available.

Whether you need a replacement or a new part, you can order conveniently via the online shop.