8 minutes

The duty cycle crawler crane that changed Liebherr

In 1979, it was a controversial topic at the ship crane manufacturer Liebherr in Nenzing – the first Liebherr duty cycle crawler crane. Yet it was to lay the foundation for the production of construction machinery at the site. After 40 years of service, the HS 870 has returned.

The homecoming of the HS 870

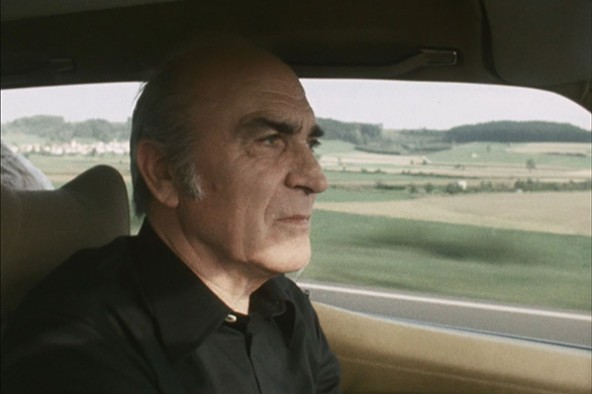

Manfred Brandl never thought that he would see this machine again one day. Yet the two are connected by a story that changed Liebherr. Why? Well, Liebherr-Werk Nenzing (Austria), where Manfred Brandl started as a production worker and left as managing director four decades later, very nearly developed completely differently and would almost certainly still be building ship cranes today: if it hadn’t been for this duty cycle crawler crane, which carried out lifting work in a gravel pit close to Bonn (Germany) day in, day out – rusty but steadfast, 40 years after it was built. It was discovered in 2014. The then sales manager for duty cycle and crawler cranes for Germany examined it himself and reported something unbelievable to his colleagues in Nenzing: he had the forefather of construction machine production in Nenzing in front of him – the prototype of the duty cycle crawler crane HS 870 with the serial number 181001. For Manfred Brandl, this reunion would become unforgettable.

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).

The forefather needs more than just a lick of paint

Jürgen Grass, Head of Assembly, has had to face more than one challenge in 35 years of working in construction machine development. Yet hardly any was as special as this one. He will probably always remember the homecoming of the HS 870 duty cycle crawler crane. That was in February 2018: “I can still see it before my eyes. Its condition was good, considering the circumstances. The motor and hydraulics were still working flawlessly. Nevertheless, time had left its mark on our first duty cycle crawler crane. In its 40 years of service, the machine wasn’t exactly handled delicately.” One thing was clear. If this part of Liebherr history was to be saved, more than just a fresh coat of paint would be needed.

But how do you restore a machine that established a whole era? “Since we are specialised in building new machines at Nenzing, we repeatedly had to decide just how much we wanted to restore. We wanted to preserve its character, of course. It was really hard for us not to make this vintage duty cycle crawler crane look as perfect as a new machine.”

Inventive talent and teamwork

A team of mechanics, fitters, engineers and apprentices got down to business. Young and old, new and experienced employees helped and lent a hand. The undercarriage was in desolate condition and required a lot of time and attention; the travel drive had to be restored completely. The steel covering had suffered during the many years of service and was built from scratch by the apprentices. Valves were renewed, hydraulic hoses replaced and old pumps and motors were dismantled into their component parts, cleaned and reassembled. Besides original replacement parts, even high-tech from the 21st century found its way into the HS 870; despite a long search, replacement parts couldn’t be found for the headlight covers, “we then replicated them with a 3D printer, true to original,” Jürgen Grass says.

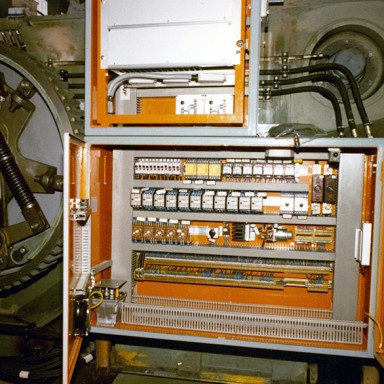

Jürgen Grass is proud of his employees. To him, the restored HS 870 is an example of what inventive talent and teamwork can accomplish. “We have many excellent and experienced employees here with us. Some of them were even involved in the construction of the HS 870, 40 years ago.” They put more than 700 hours of work into the restoration, on top of their daily work in production. A master performance during which all those involved were able to experience history up close. “This is why it was so important to us to include our apprentices in the restoration. For them, everything was particularly exciting. They could experience how our HS series first started. Today our duty cycle crawler cranes are completely digital, in 1980 everything was still analogue.”

How did Liebherr come to Nenzing?

At Liebherr-Werk Ehingen (Germany) the space became too cramped to build maritime cranes at the beginning of the 1970s. The company’s founder, Hans Liebherr, went on the lookout for a new site. He knew that if too many products were built at too small a site, there would be no room for further development. After some searching, a suitable place was found in the border triangle between Germany, Austria and Switzerland. Liebherr-Werk Nenzing was founded in 1976. In 1977, the year the first Star Wars movie came to the cinemas, production began. Less than 100 people made up the workforce and they were proud to build the Group’s ship and offshore cranes in the Alps.

New territory in the Alps

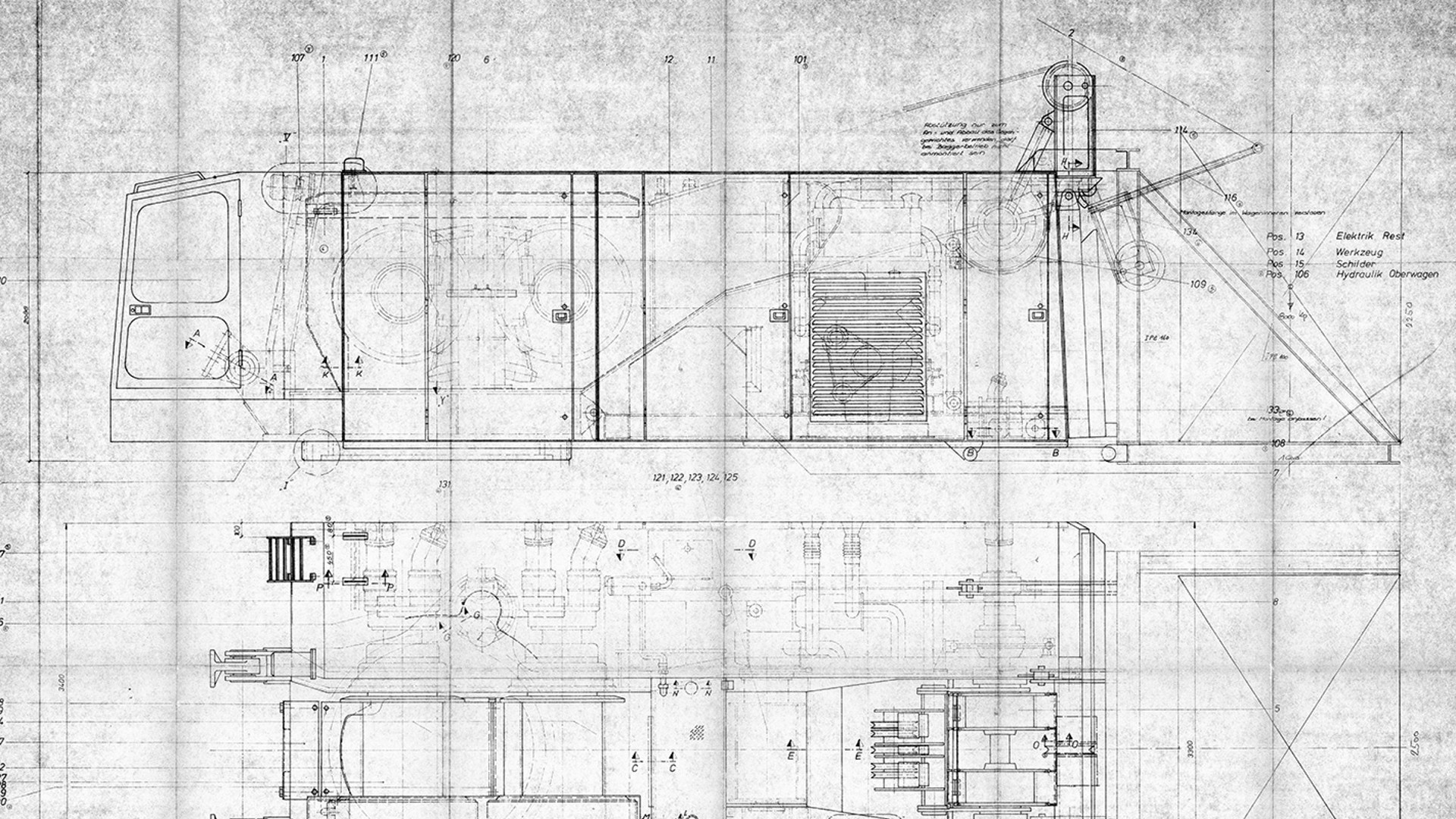

In the analogue years 1979 and 1980, neither Manfred Brandl nor his colleagues would have guessed that their work was to go down as a turning point in Liebherr history. It all began when the German construction machine manufacturer Menck went bankrupt. At the same time, many different contractors approached Hans Liebherr Jr, asking whether his company could also build duty cycle crawler cranes. The company founder’s son bought the bankrupt manufacturer’s construction plans. After careful consideration, they decided to build a duty cycle crawler crane in Nenzing. And Manfred Brandl became part of the group that built it. He remembers that, initially, the prototype wasn’t popular with everyone: “We were a ship crane factory and had little to do with construction machines. The duty cycle crawler crane was a completely different product and did not really fit into the production portfolio. A few were grumbling behind closed doors.”

In spite of the naysayers, it was to be a duty cycle crawler crane, and by no means simply a Menck machine under a new name. The first Liebherr duty cycle crawler crane was to have a diesel-hydraulic drive and an electronic control system. A world’s first to be presented at Bauma 1980. However, there were only 18 months left until then. “At first, things were frantic,” says Manfred Brandl. “After all, we didn’t even know how a duty cycle crawler crane worked and to some extent, we had to define completely new manufacturing processes.” Equipped with the construction drawings of the Menck model M 750, the design engineers went to the drawing board and drafted a machine unknown to them, with novel hydraulics and a new drive system. “We mechanical fitters in production received the construction plans pretty quickly and we got started. It was only during construction that we noticed that Menck’s construction drawings were incomplete. There was a hitch in every corner.” As a group, they worked together to find the mistakes – not unlike today’s agile way of working – and together they found solutions for all the problems. “Building ship cranes is a project business. You can blindly rely on others. And that’s the only reason why we managed to build the HS 870 at maximum speed.” They even worked on their duty cycle crawler crane on the weekends – as a truly committed team.

That darn band brake

When Manfred Brandl thinks back today, he fondly remembers the assembly, the production of the covers and the tests on the test bench. And a very particular component: that darn band brake! Without a band brake, there’s no rope winch, no rope and definitely no working duty cycle crawler crane. “I would never have thought that a small, inconspicuous component could drive us to the brink of despair. As simple as it looked, as complex was its construction.” Every time they thought they had finally found the solution for the brake, a new problem arose. Some versions saw the metal getting too hot when braking, with others, the metal simply broke or the rivets fell out. Nothing worked. “We even dreamt about it. However, when Bauma came, we had it figured out. Our motto prevailed: nothing’s impossible.”

The beginning of a new era

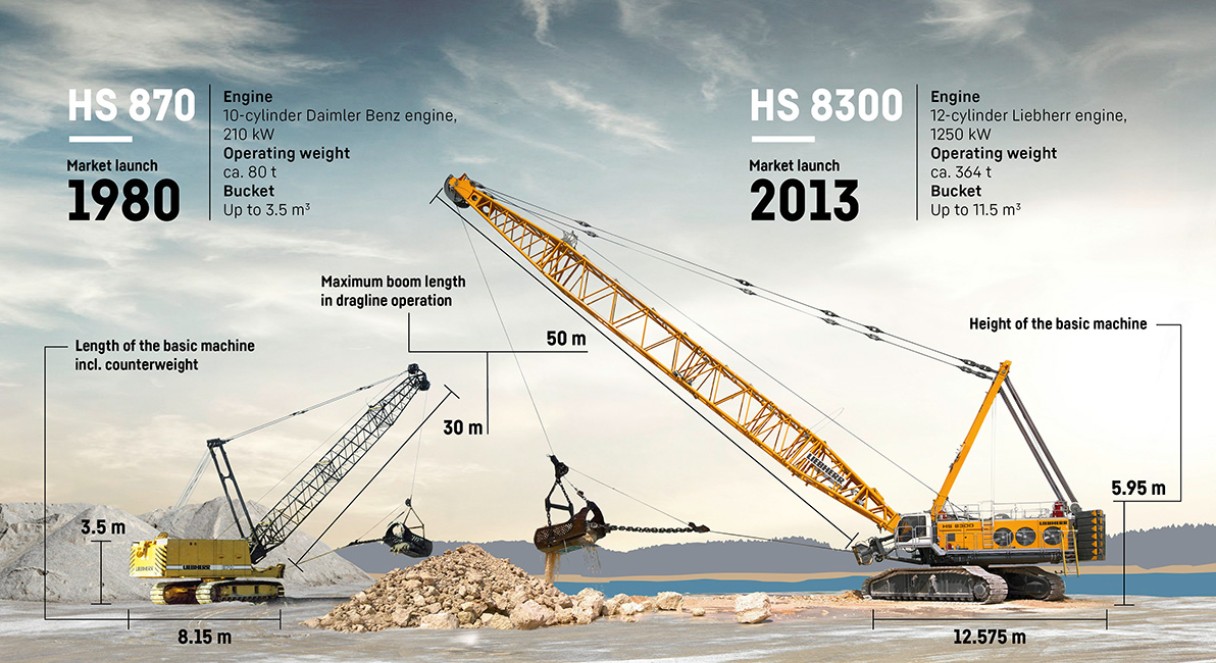

Following the HS 870, at Bauma 1983 the HS 840 was released – and after that, a whole generation of construction machines Made in Austria. In the early 2000s, the Liebherr Rostock site was opened, where the Group’s maritime cranes are built today. Liebherr-Werk Nenzing became a reputable construction machine manufacturer. Today, its machines work on construction sites all over the world, including numerous duty cycle crawler cranes, the HS Series. The Austrians’ latest hit is the Unplugged series, battery-powered crawler cranes and deep foundation machines that are setting trends in the industry.

In April 1980, the whole group that had created Liebherr’s first duty cycle crawler crane was invited to Bauma in Munich (Germany). The prototype was not only expected to meet high standards in terms of workmanship and functionality: it also had to be visually appealing. “We cleaned and polished the machine until in the end it was presented to the world like a made-up bride on the Liebherr stand.” The group from Nenzing stood around their machine with proudly swollen chests, watched the hustle and bustle, held conversations and could hardly believe just how much praise they got. “At Bauma all the reputable construction machine manufacturers of the world present their products but our HS 870 caught the eye of the expert exhibition visitors. It was a world sensation.”

When Bauma ended, the prototype was directly handed over to its new owner Bilfinger Berger and was in active service on various construction sites for various owners all over Europe: until it was rediscovered in Bonn, 40 years later.

Two "Liebherr old-timers“ retire

The day he said his goodbyes after more than four decades with Liebherr, the retiring Managing Director Manfred Brandl was quite astonished when his staff presented him with his namesake Manfred #1. “The restoration of the HS 870 was finished at the same time as my retirement after 42 Liebherr years. As a farewell present, so to speak, my first name now adorns this amazing machine. I’m very thankful for this and it makes me proud to be part of this Liebherr history.”

The HS 870 is staying in Nenzing where guests and employees can visit and admire it. In future, the first Liebherr duty cycle crawler crane will also be presented during customer days and events. Only one question remains: what would the prototype, the machine that laid the foundation for the construction machine production in Nenzing, say to all of this? Manfred Brandl and Jürgen Grass agree: “If the HS870 could speak, it would probably say that it owes its existence to the proverbial “Liebherr spirit” and that it is pleased to return to Nenzing for its retirement after so many years.”