Slew drives

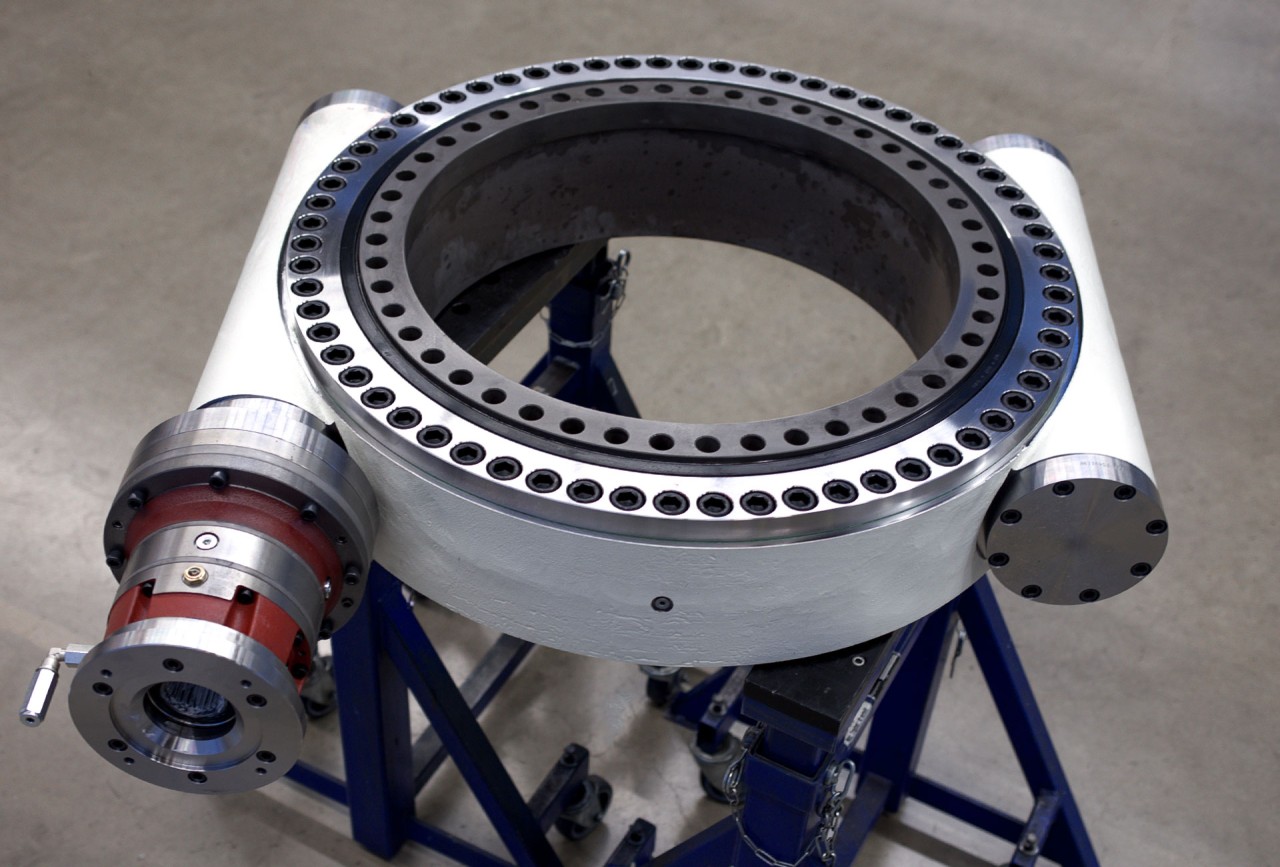

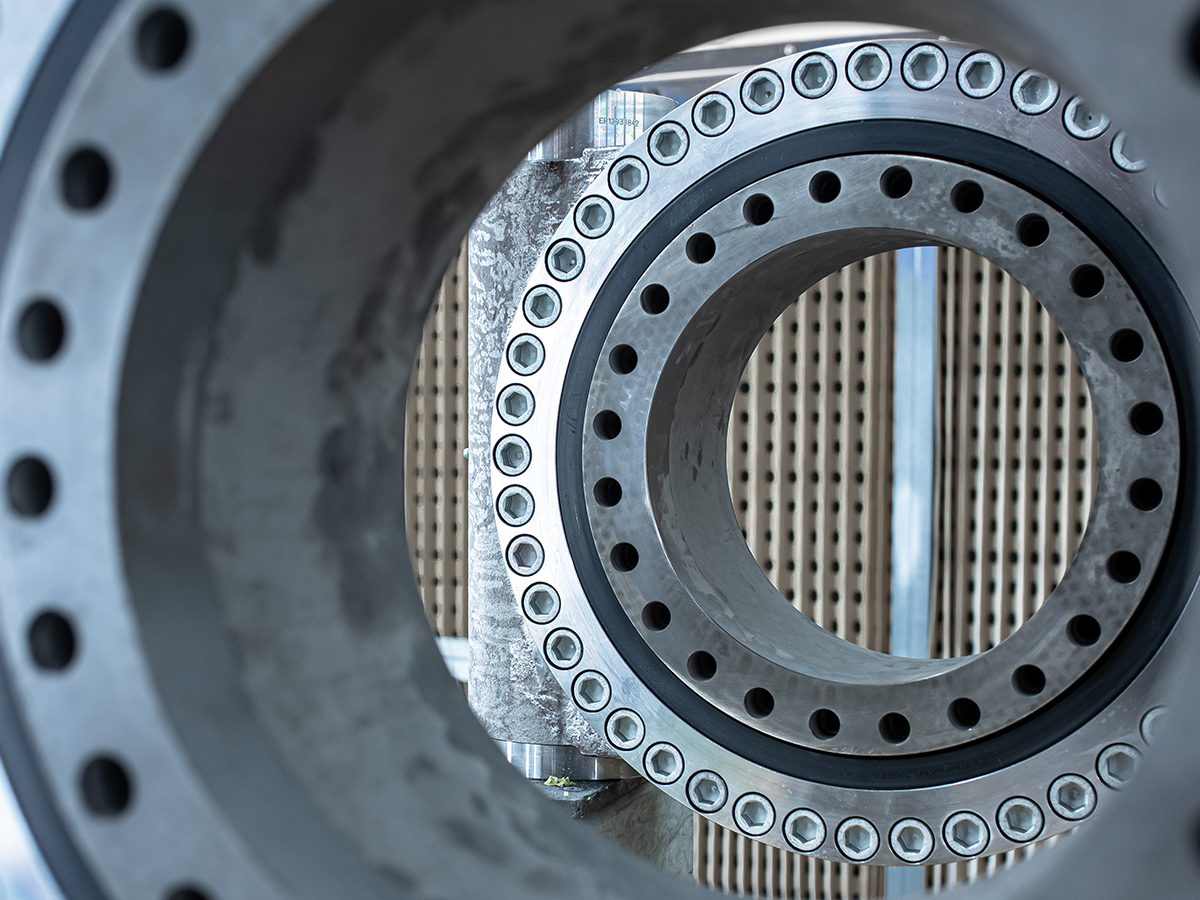

Liebherr slew drives

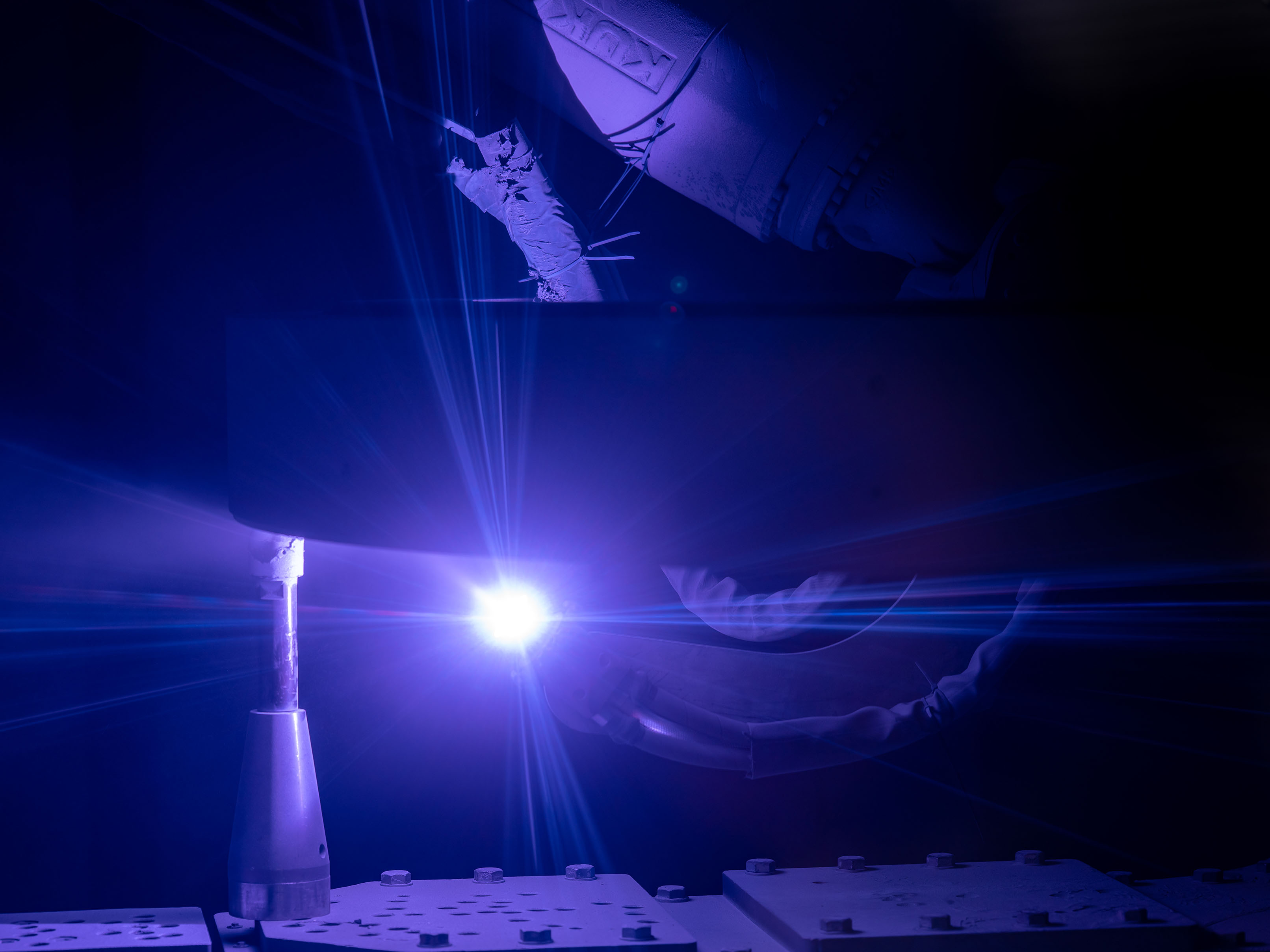

Benefit from high power density, easy installation, high serviceability and top consulting services. Decades of experience in the manufacture of high-quality components form the basis of Liebherr slew drives; a product whose elements are in perfect interplay with each other.

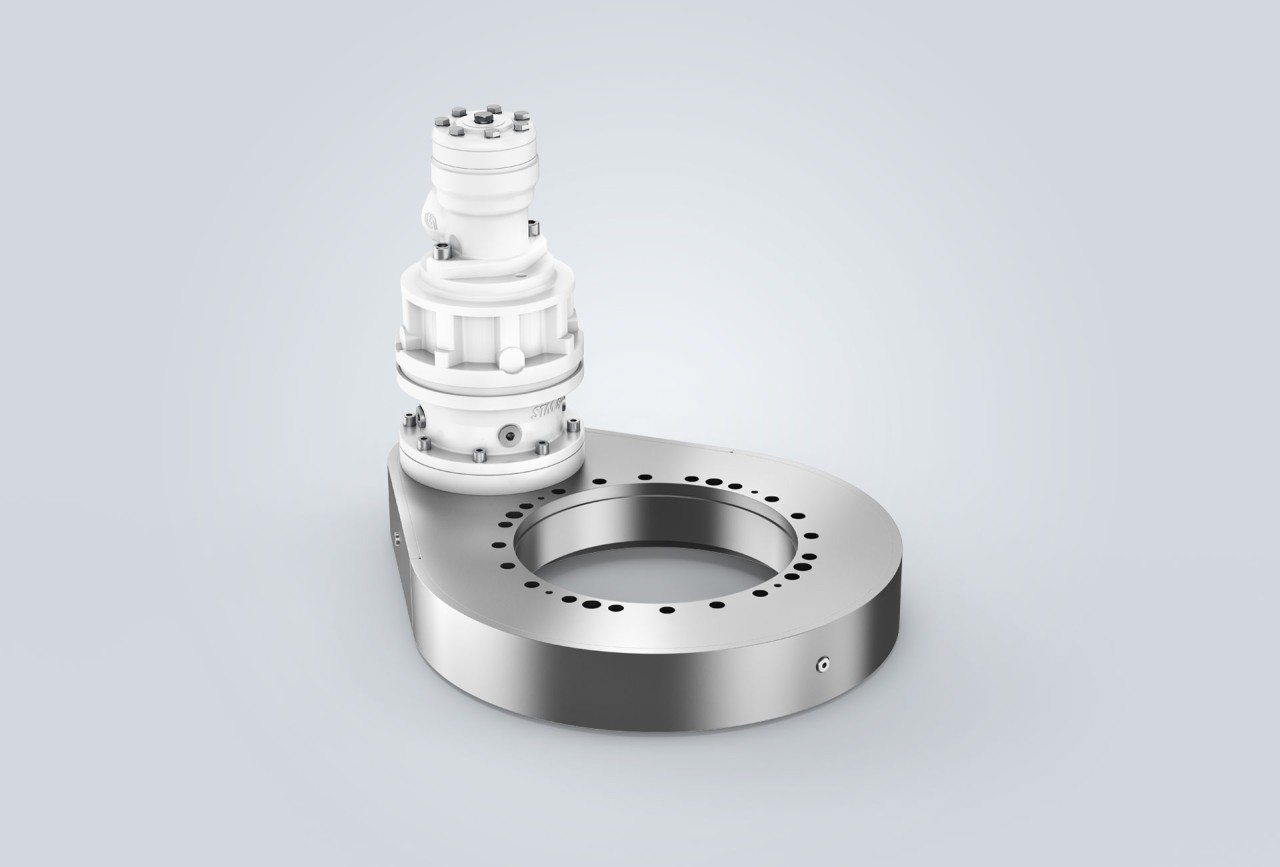

Great power in a small space

Plug & Play

Low2no maintenance

Your application. Our solutions.

With worm slew drives, spur gear slew drives and belt slew drives, the Liebherr portfolio includes a wide range of solutions for steering, turning and swiveling applications. By designing the complete system for optimal adaptation to your application, you don‘t just get a product, but customized solutions.

01/03

Request 3D models now!

Signature line

Rely on additional product features and services. With the premium line option Liebherr Signature.

Example applications

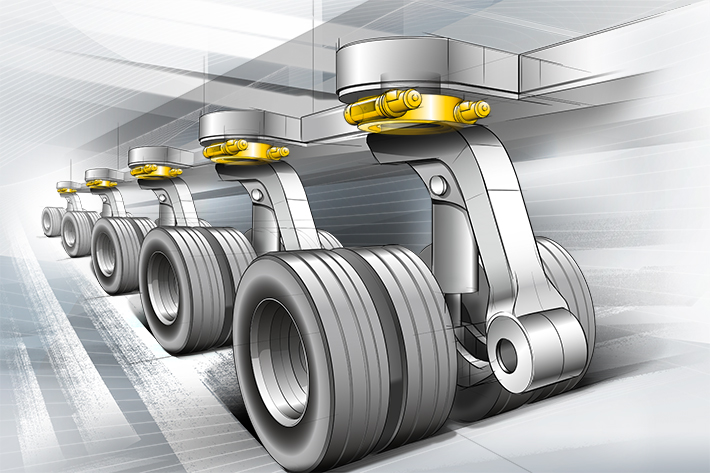

Steering gearboxes

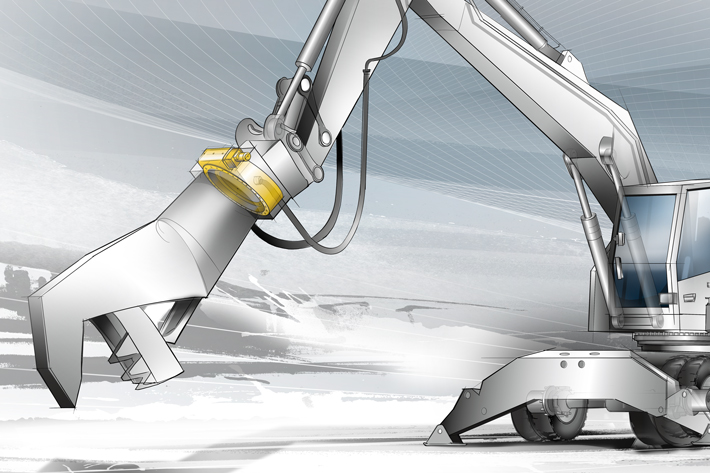

Attachment tools

Boom arms

Get in touch

Contact our local sales team or follow us on our LinkedIn channel.