Field experience

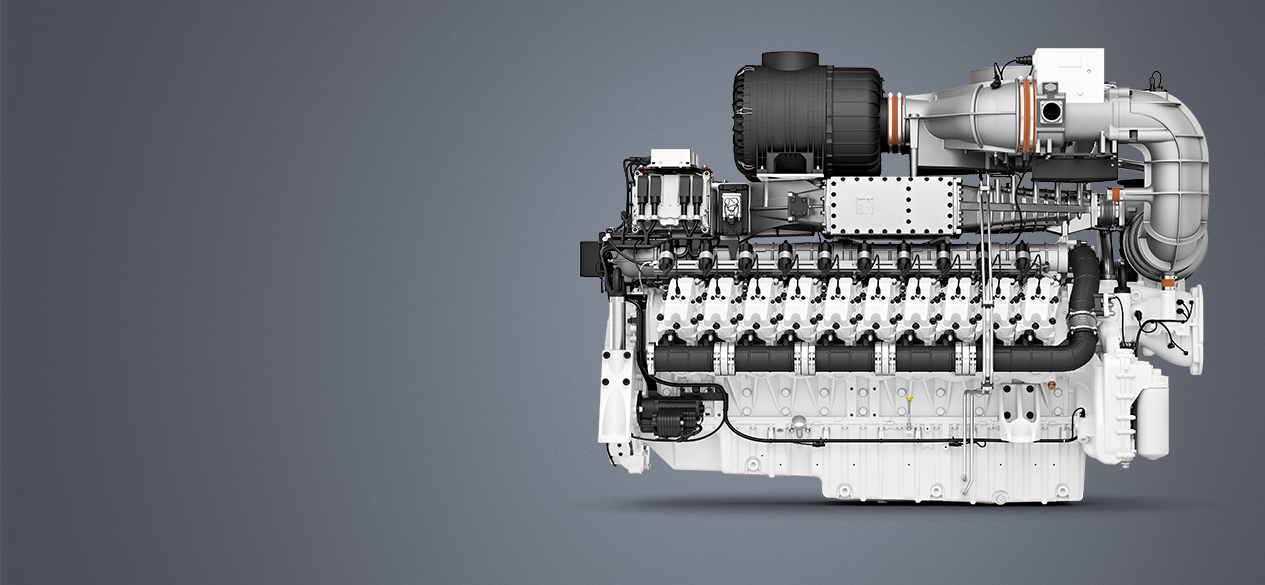

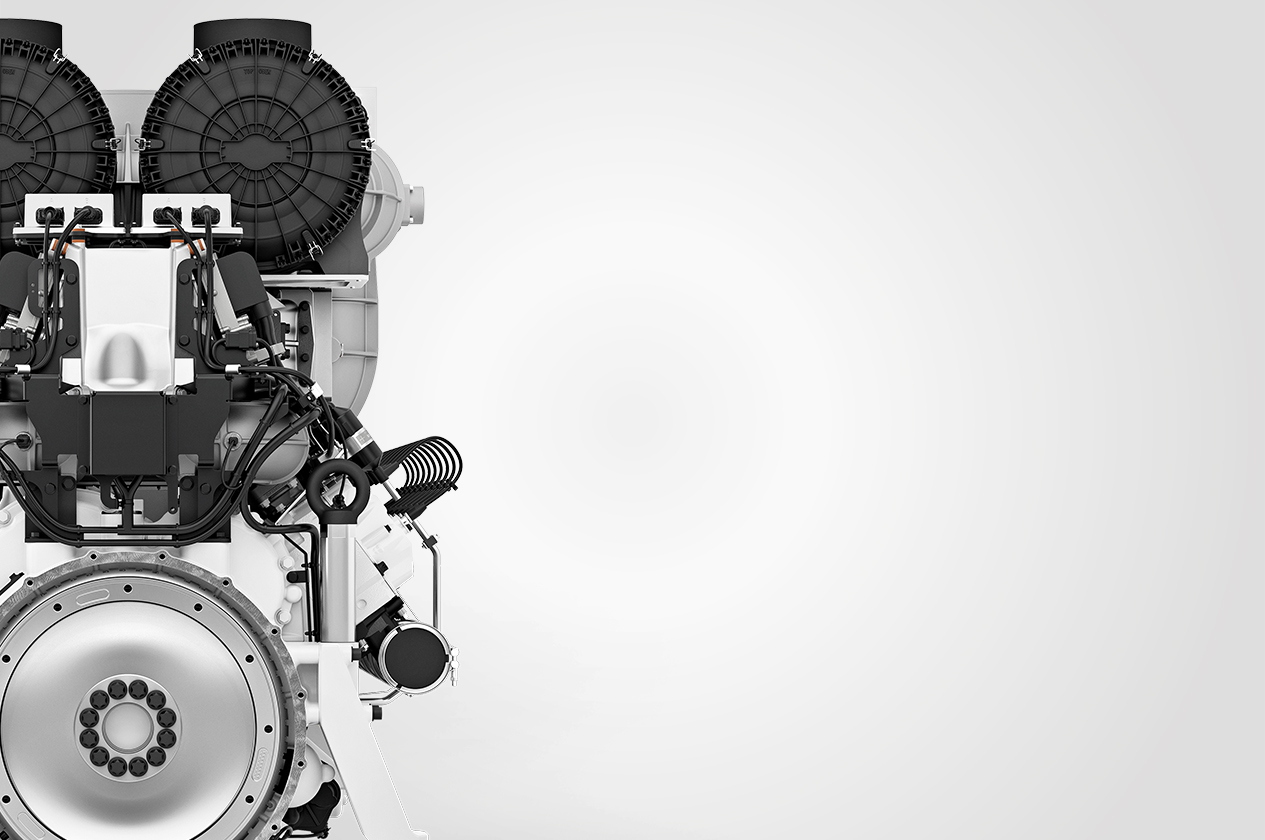

After the field-testing, the new generation G9620 engine now features:

- mechanical efficiency of over 43.9% at nominal power of 1,060 kW mech.

- total efficiency of up to 88%, including the heat of the exhaust gases, lube oil and jacket water

- long-term reliability upon industrial operation for CHP, as well as power generation with natural gas due to design modifications

- a life cycle of 64,000 operating hours for the base components in continuous operation at full load

- improved engine control system based on Liebherr`s own ECU

- improved materials and a specially designed ignition system to reduce down times, as well as maintenance to a minimum

- high availability throughout the entire life cycle of the gas engine

Once upon a time in Bulle (Switzerland)

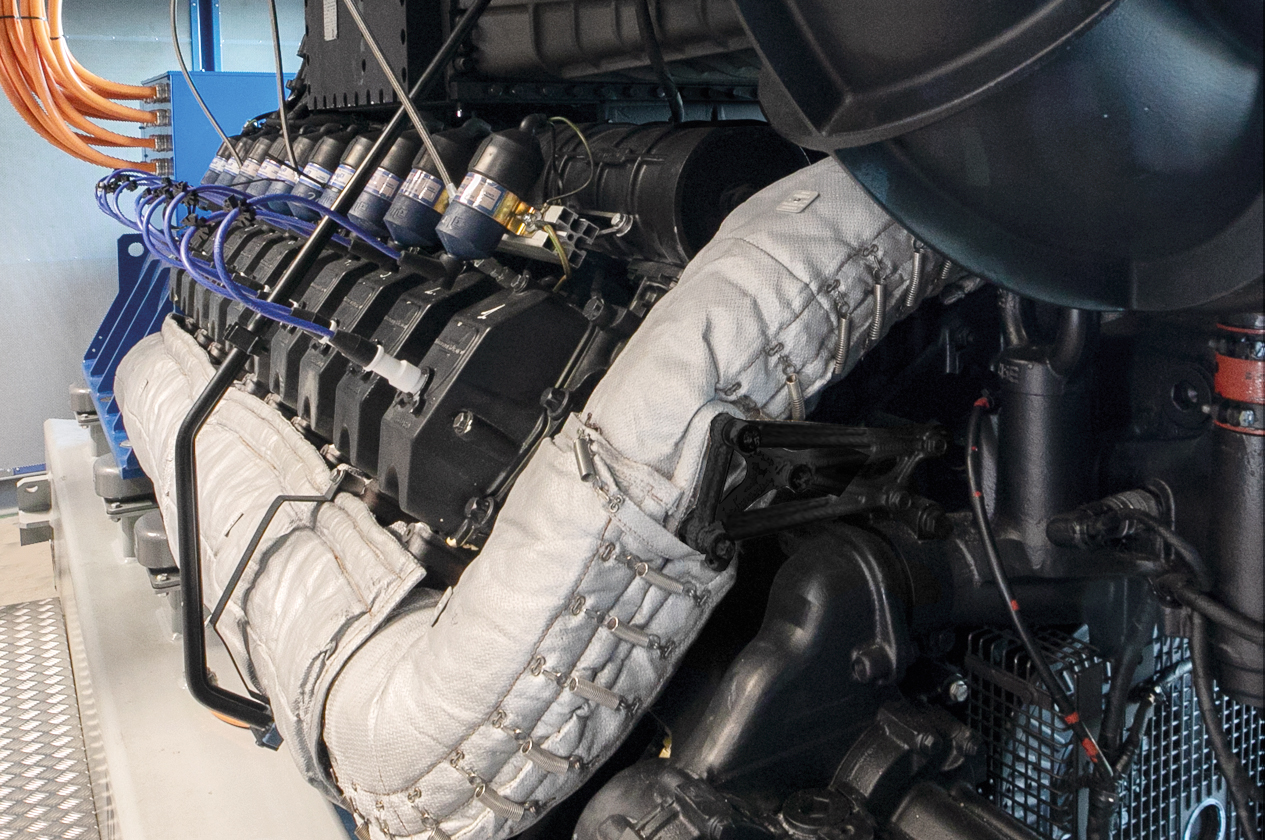

Once, the idea was born to join forces and launch a mutual project for the use of excessive energy. Thereupon, Gruyère Energie SA erected a new heating plant less than 100 meters away from the Liebherr site. This was the perfect chance for Liebherr to start testing the new G9620 at a partner plant in addition to the in-house tests.

The story so far

Four years have passed since the beginning of the cooperation. In the meantime, both companies have resolved the common objective – not only to solve the energy storage equation, but also to optimise and rationalise its use. As a result, a CHP system with a G9620 on board was installed at Gruyère Energie`s new heating plant.

Gruyère Energie

On the one hand, the cogenerated heat helps to recover the thermal waste from the Liebherr factory and to redistribute it into the Gruyère Energie heating network. Furthermore, the generated electricity increases the security of electricity supply of Bulle and the share of their own production.

Liebherr

Our engineers have carried out all the necessary tests and improved the G9620. In addition, the project still allows us to recycle the thermal waste at the factory in summer and to heat the buildings in winter.