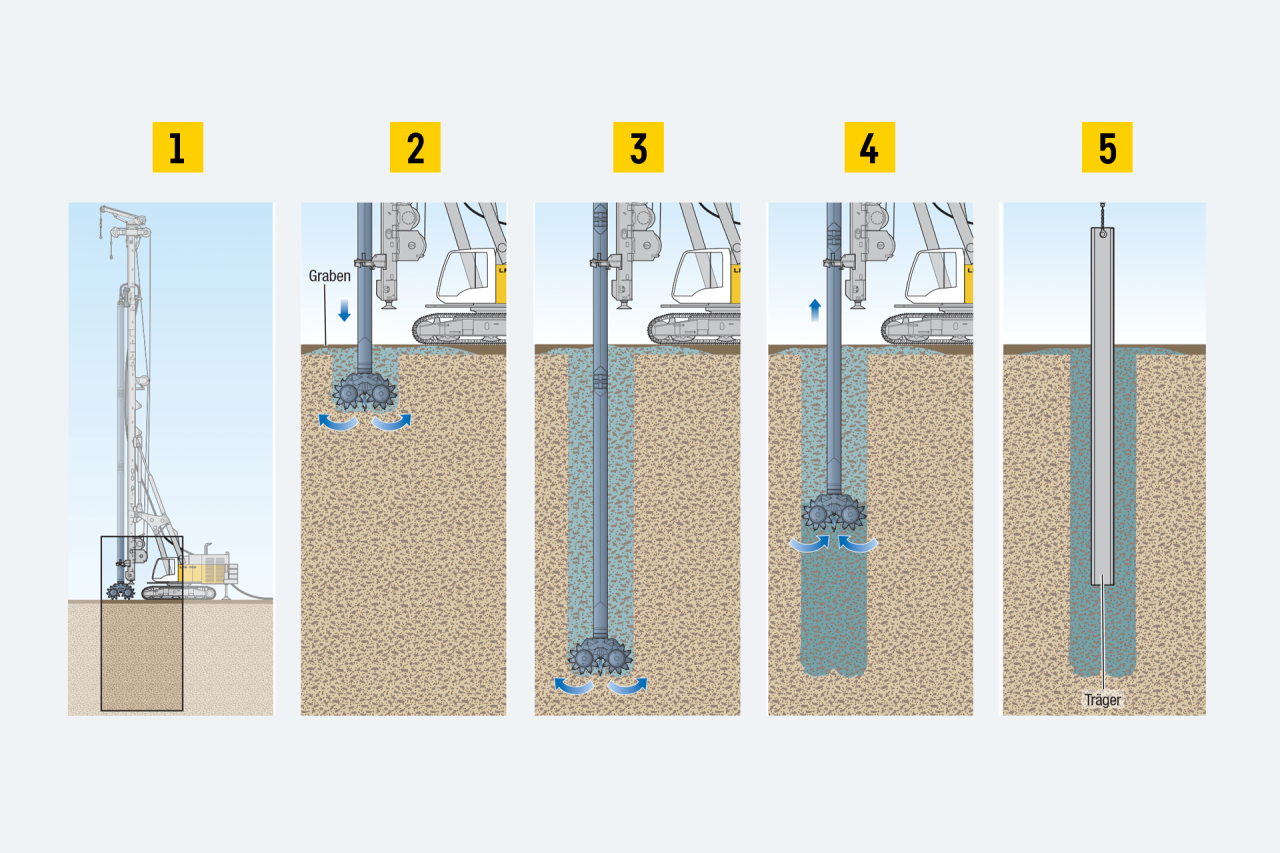

For cutter soil mixing rotating drums break up the soil structure. Simultaneously a self-hardening binding agent suspension is added. The binding agents used are mainly cement types or mixtures of cement and bentonite. These are mixed with water to form a suspension. The drums of the mixing tool rotate around the horizontal axis so producing soil mixing elements with a rectangular cross-section.

01/06

Video cutter soil mixing

The video shows an LRB 255 piling and drilling rig applied for cutter soil mixing.

Machines

Results 1-2 of 2