9 minutes | magazine 01/2022

High tech from the Kaiser’s time

On the morning of 8 January 2016, as on every other school day, a host of children on their bicycles headed towards the suspension ferry on the edge of the town of Rendsburg. The shortest route to the schools in the northern German town was over the Kiel Canal.

Liebherr cranes reinstall repaired Rendsburg suspension ferry

Suspended on long steel cables under a high railway bridge, the ferry, a nostalgic vehicle dating from the 1910s, carries cars, pedestrians and cyclists over this very busy waterway. The two minutes or so that the crossing takes is always a welcome break for the children. On that January morning, however, the route to school initially ended at the boarding point. The ferry hung in the air, badly damaged and immobile over the middle of the canal. Salvage vessels were just arriving. It was a great spectacle for the children. In the early morning, the gondola of the suspension ferry had collided with a freighter in the dark.

Steel, steel, steel: Large rivet heads dominate the surfaces of the steel bridge structure. The impressive construction is held together by over three million rivets.

The damage to both the vessel and ferry at the time was massive. Two people suffered injuries on the gondola, which was fortunately not busy due to the early hour. The historic ferry suspended under the railway bridge dating from the time of the German Kaiser was irreparable. Together with its travel gear at a height of around 40 meters, it was completely dismantled over the following months. Last autumn, the completely newly manufactured components for the ferry system were then reinstalled. Several of our cranes played leading roles in the repair project.

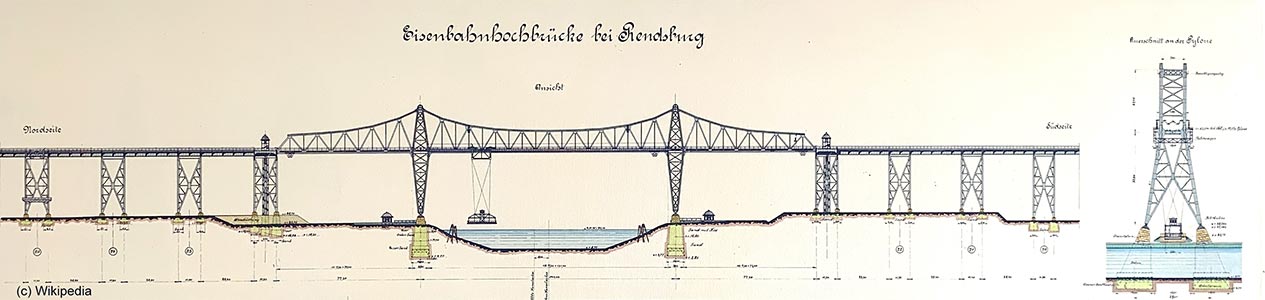

The high railway bridge in Rendsburg is one of the outstanding engineering monuments in Germany. It was built between 1911 and 1913 and is part of the railway track to Denmark. The clearance height for vessels on the canal travelling between the North Sea and Baltic Sea is 42 meters. The gradient for trains to achieve this height starts several kilometers before they reach the canal. What makes this steel bridge held together with millions of rivets very special is the ferry gondola suspended on from its underside, which provides free passage over the waterway “floating” a good three meters over the surface of the water. There are only eight of these suspension ferries still in operation around the world. However, the damaged vehicle in Rendsburg is the only one of them which is suspended from a railway bridge.

More than twice as much steel as the Eiffel Tower

Technical aesthetics or aesthetic technology: The bridge structure today is a monument and was celebrated around 110 years ago as a masterpiece of engineering.

The whole thing is absolutely massive. The construction of the steel bridge and ramp structure measuring almost 2,500 meters in length required a total of 17,300 tonnes of steel. Well over twice the volume required for the erection of the Eiffel Tower in Paris. The whole structure has a length of 7.5 kilometers and at the time was completed in a construction period of just less than three years. That is an amazing fact when we consider that well over 100 years later, it took a full six years simply to replace the suspension ferry. Bureaucracy, placing orders and technical challenges such as the installation of safety equipment all took an enormous amount of time. In addition, the pandemic put paid to the plan of the Waterways & Shipping Department to repair the system as quickly as possible. The timetable was corrected multiple times, and the restarting of commuter traffic over the canal was postponed time and again. But last summer, at last everything was finished – the new ferry had been completed and could be installed.

Teamwork – Stefan Heldt, Managing Director of Wille & Dulies Krane GmbH (right) planned the crane work at the high bridge in Rendsburg along with Ralf Rohwer from the metal and steel construction contractor of the same name. Photograph: Ines Krisch / Rohwer Stahl- & Metallbau GmbH

Pulley heads extremely close to the bridge structure

During September, mobile cranes from Wille & Dulies Krane GmbH based in Harrislee near Flensburg, provided support for Wille-Krane in Kiel, travelling to Rendsburg on several occasions. At the site on the southern bank of the canal, the first stage was to install the drive section at a height of over 40 meters using two cranes directly under the bridge level. In addition to a modern 250 tonne mobile crane, the most powerful vehicle in the Wille crane fleet, an LTM 1450-8.1, also took up its position on the bank.

A fairly complicated job awaited the two crane operators, Florian Clausen and René Nestler. They had erected their Liebherr cranes either side of the massive truss pillars to tackle the tandem hoist. “Because the gondola is narrower than the bridge structure itself and the tips of the telescopic booms therefore had to be moved extremely close to the bridge, the installation process was certainly rather fiddly”, is how Ralf Rohwer explained the challenges on site. Rohwer and his company, which specialises in steel and metal construction work, completed the installation of the new ferry system on the monument. “At times, we had a gap of less than 50 centimeters between the bridge and pulley heads during the complex process to get the drive unit rollers of the wagon up onto the rails.”

Soon to be suspended again – Two Liebherr mobile cranes move the new 44 tonne gondola from the pontoon onto land. The ferry will be able to carry one hundred people and four cars. Photograph: Ines Krisch / Rohwer Stahl- & Metallbau GmbH

Sea trip – The pontoon had to undertake a journey of around 200 kilometers to get to Rendsburg. The components of the new suspension ferry were manufactured in Brake (Unterweser) over a period of two years. Photograph: Ines Krisch / Rohwer Stahl- & Metallbau GmbH

The precision balancing of the load on the crane hooks, and the complicated installation on the underside of the bridge took a great deal of time. Finally, the larger crane had to be moved to install the drive unit on one side of the gondola – another very tricky process requiring centimeter precision at a great altitude and therefore once again something of a challenge for everybody concerned. “Ultimately, everything worked really well,” says Rohwer very satisfied with a job well done.

Unique – the suspension ferry in Rendsburg is the only one in the world to be suspended from a railway bridge. The gondola takes around two minutes to complete the 140 meter crossing. This photograph shows the ferry before the accident.

Space for four cars and 100 people

The hoisting of the actual ferry, known as the ferry platform, one week later was rather routine, on the other hand. This job was tackled by two LTM 1450-8.1 cranes and was comparatively straightforward. The mobile cranes hoisted the 44 tonne gondola off the pontoon which had been towed to the bridge in the morning. The load was aligned and positioned precisely on wooden supports under the bridge. The white ferry gondola was then attached to the ferry vehicle in this position.

The Rendsburg suspension ferry will now be able to carry up to four cars and one hundred people in its transport gondola. The new structure, which looks very similar to the original, was manufactured over a period of two years in Brake near Bremen and towed to Brunsbüttel on waterways via the River Weser, North Sea and Elbe Estuary and from there on the Kiel Canal to Rendsburg.

Commuters and tourists now hope that after the winter months, the test phase and trial period for the new ferry system will be completed and normal operations will be restarted. However, above all, the children who for many years have had to take the longer route to school will be delighted. And they can once again take a welcome break on the suspension ferry dating from the time of the German Kaiser.

This article was published in the UpLoad magazine 01 | 2022.