Liebherr driver assistance systems - increased performance through efficient crawler dozer blade control

In the face of the constantly increasing pressures on time and costs, construction machines have to meet the highest demands, both in terms of speed and precision in operati-on, in order to win through. For this very reason, automatic machine control and operator assistance systems are being used ever more extensively to increase the productivity of operator and machine.

These make use of digitised planning data to automatically control the machine equipment when removing or laying down material. With the assistance of the latest technology, it is possible to produce complex surface areas and exact grading both quickly and precisely.

Because of their innovative drive systems, Liebherr crawler dozers are ideally suited to the application of automatic con-trols. The hydrostatic drive ensures smooth propulsion, free from gear changes and jerky movements. Optimum grading properties are ensured due to the long running gear and the perfect match of front equipment to the operating hydraulics and the base machine. The low centre of gravity enables safe operation even on steep slopes and steeply inclined terrain.

The right control technology for every application

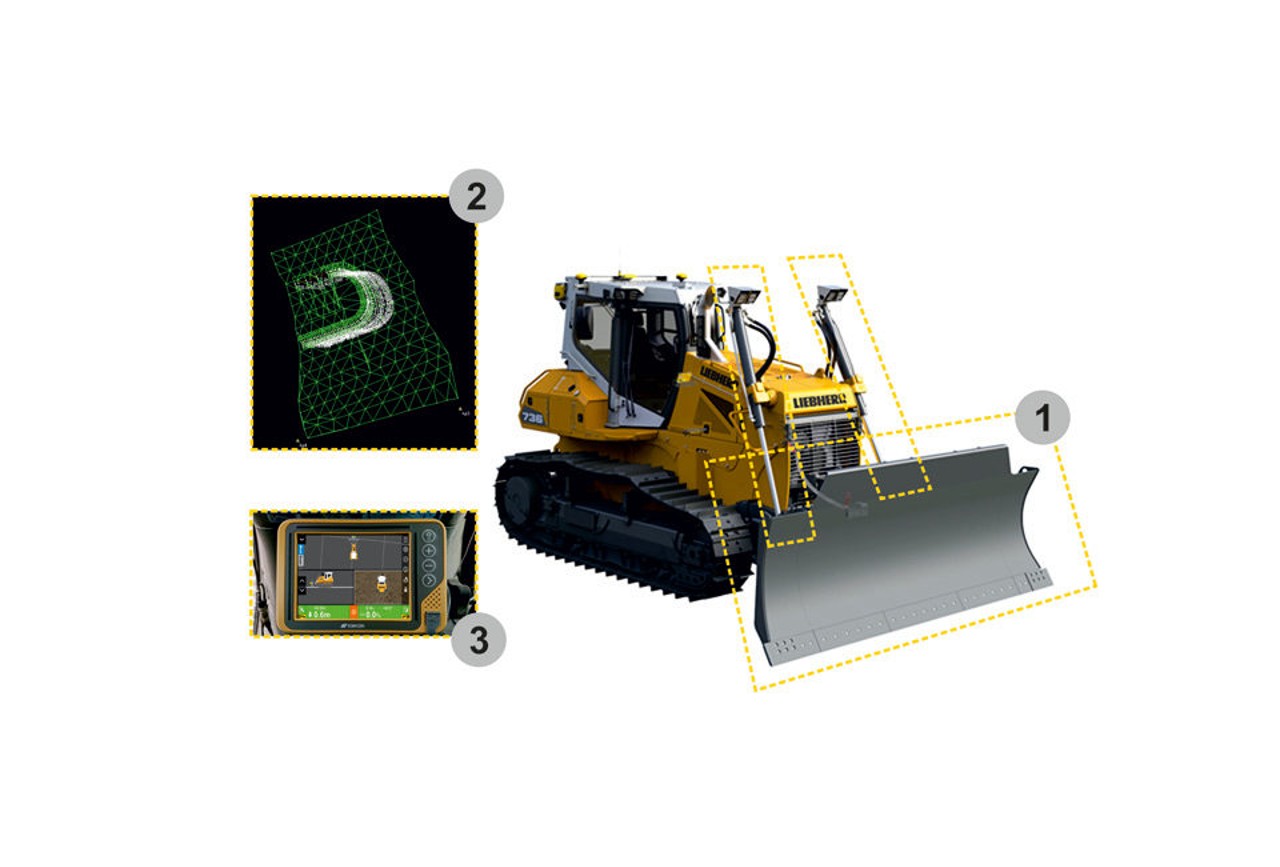

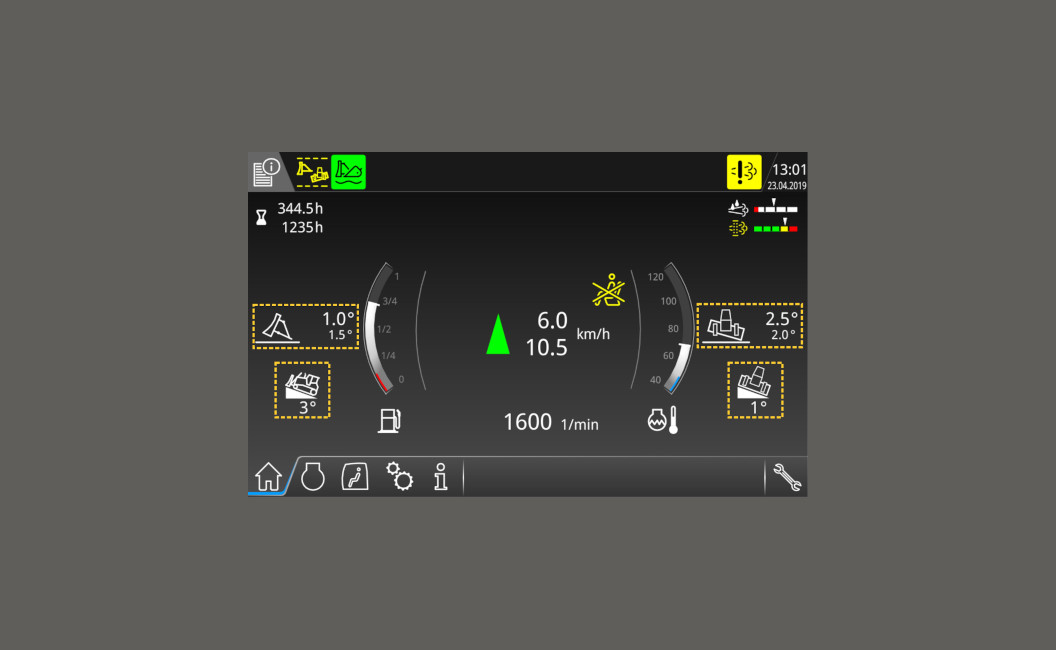

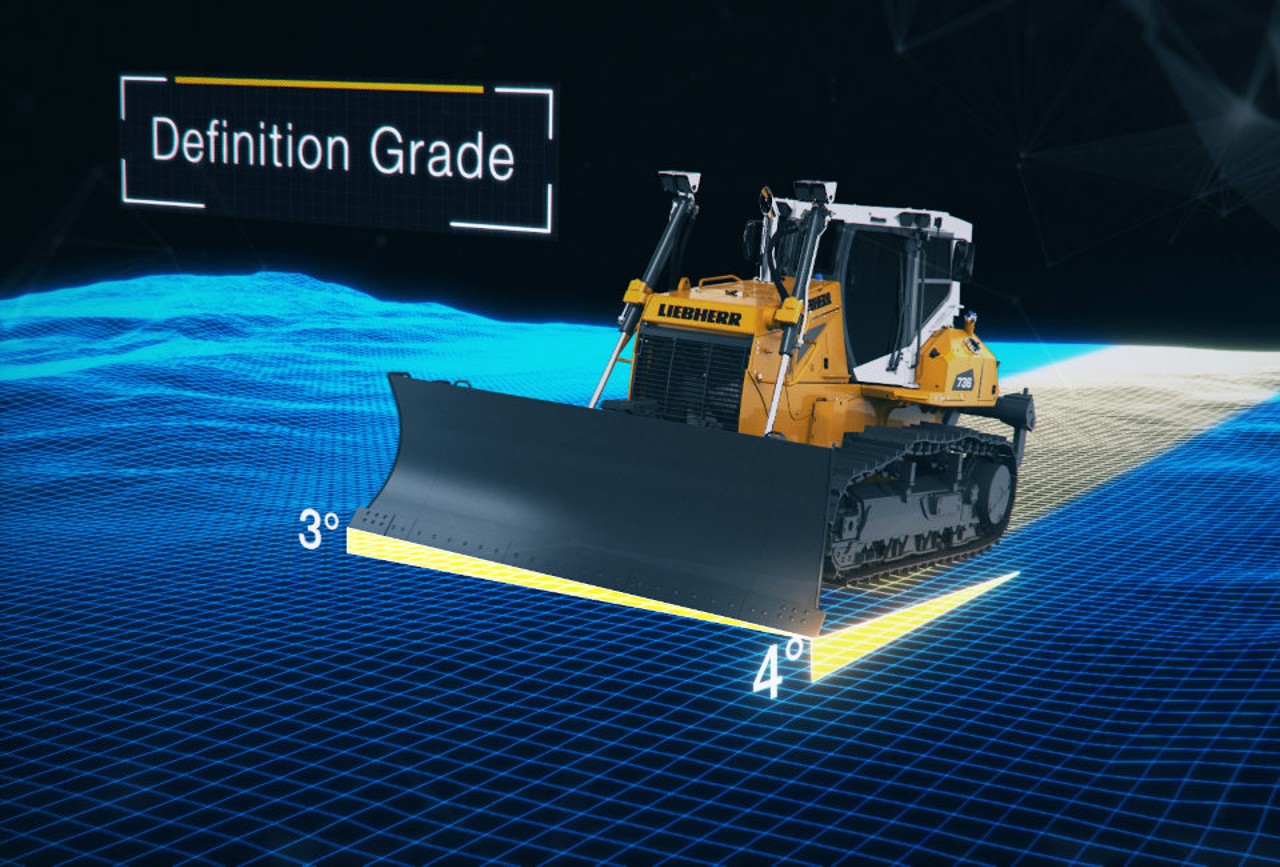

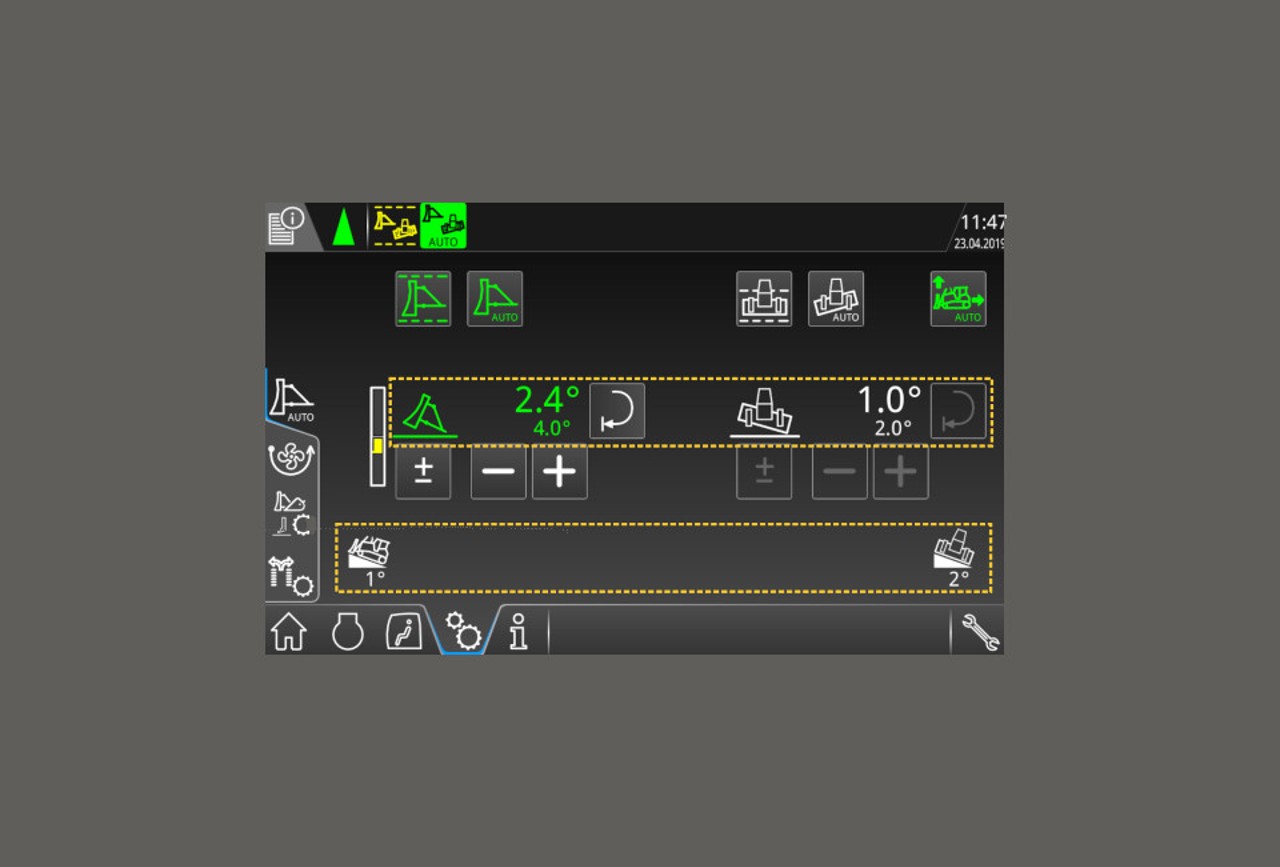

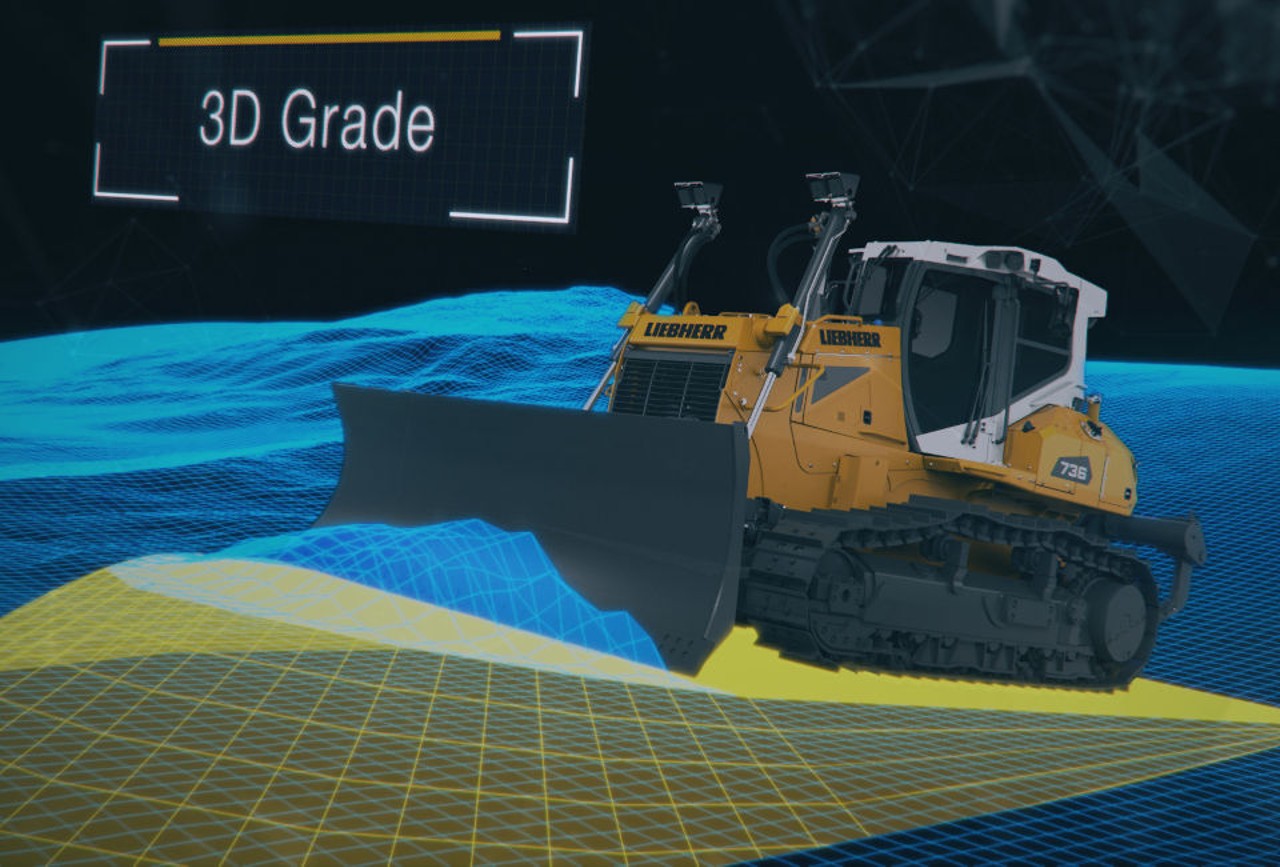

The new assistance systems in generation 8 crawler dozers include three levels of driver support: Free Grade for active blade stabilisation during fine grading; Definition Grade for automatic blade positioning when creating simple 2D surfaces, 3D Grade from Topcon as optional GNSS machine control for modelling complex terrain forms. In addition, the option is available to order factory installed ready-kits, which allow a range of machine control systems from Trimble and Leica to be retrofitted in the field.