Aerospace and transportation systems

Aerospace and transportation systemsDriving innovation for improved efficiency in aerospace

Liebherr is at the forefront of innovation, offering advanced solutions like the smart integrated wing, folding wingtip mechanisms, and additive manufacturing technologies. By enhancing aerodynamics, reducing weight, and partnering on breakthrough engine systems like the UltraFan®, Liebherr plays a vital role in creating more efficient and more sustainable next-generation aircraft.

Less energy consumption

Reducing energy consumption on airplanes is a crucial step toward a more sustainable future in aviation. By optimizing flight paths, utilizing more fuel-efficient engines, and adopting lighter materials in aircraft design, airlines can significantly cut down on fuel usage, reducing both operational costs and carbon emissions.

Innovations such as electric and hybrid engines are also paving the way for greener skies, ensuring that air travel remains a viable option. Lower energy consumption not only benefits the planet but also creates a more efficient and cost-effective aviation industry.

Advanced pneumatic systems improve efficiency

Engine bleed air systems bleed high pressure, high temperature air from the engine's low and high pressure ports. The air flow is processed through temperature and pressure control devices and supplied downstream to the aircraft's main air- conditioning system, to the airframe anti-icing system and to the main engine starting system. For improved efficiency, the system features light-weight, robust and highly reliable components as well as an optimized control architecture.

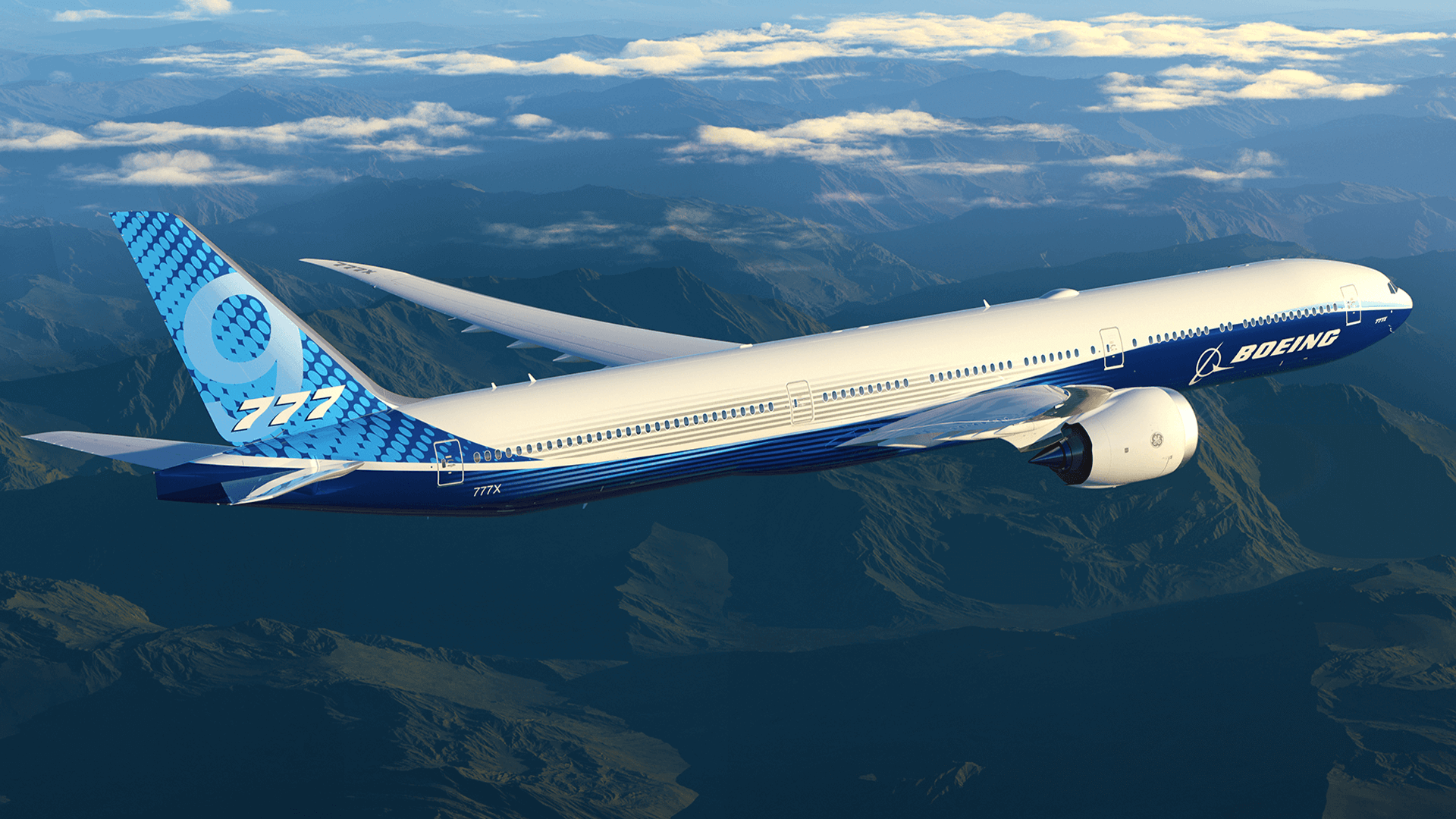

Improved aerodynamics

Improved aerodynamics in aircraft design is a game-changer for the aviation industry, leading to enhanced fuel efficiency and reduced emissions. By refining the shape of airplanes, reducing drag, and optimizing wing design, manufacturers can create aircraft that glide more smoothly through the air. These aerodynamic advancements decrease the energy required to maintain flight, resulting in significant fuel savings and lower operational costs. Beyond economic benefits, improved aerodynamics contribute to a more sustainable environment, helping airlines meet sustainability goals and reduce their carbon footprint, all while maintaining optimal performance and safety standards.

Smart integrated wing

Liebherr is advancing next-generation aircraft with more electric architectures, exemplified by its smart integrated wing demonstrator. Funded by Clean Sky 2, a Clean Aviation initiative of the European Union, this project integrates sub-systems from national research efforts, focusing on electrical and hybrid wing actuation systems. It also enables synergies with systems like landing gears. Fly-by-wire controls and a high-voltage DC power actuation network are central to Liebherr’s vision for sustainable, next-generation aircraft systems.

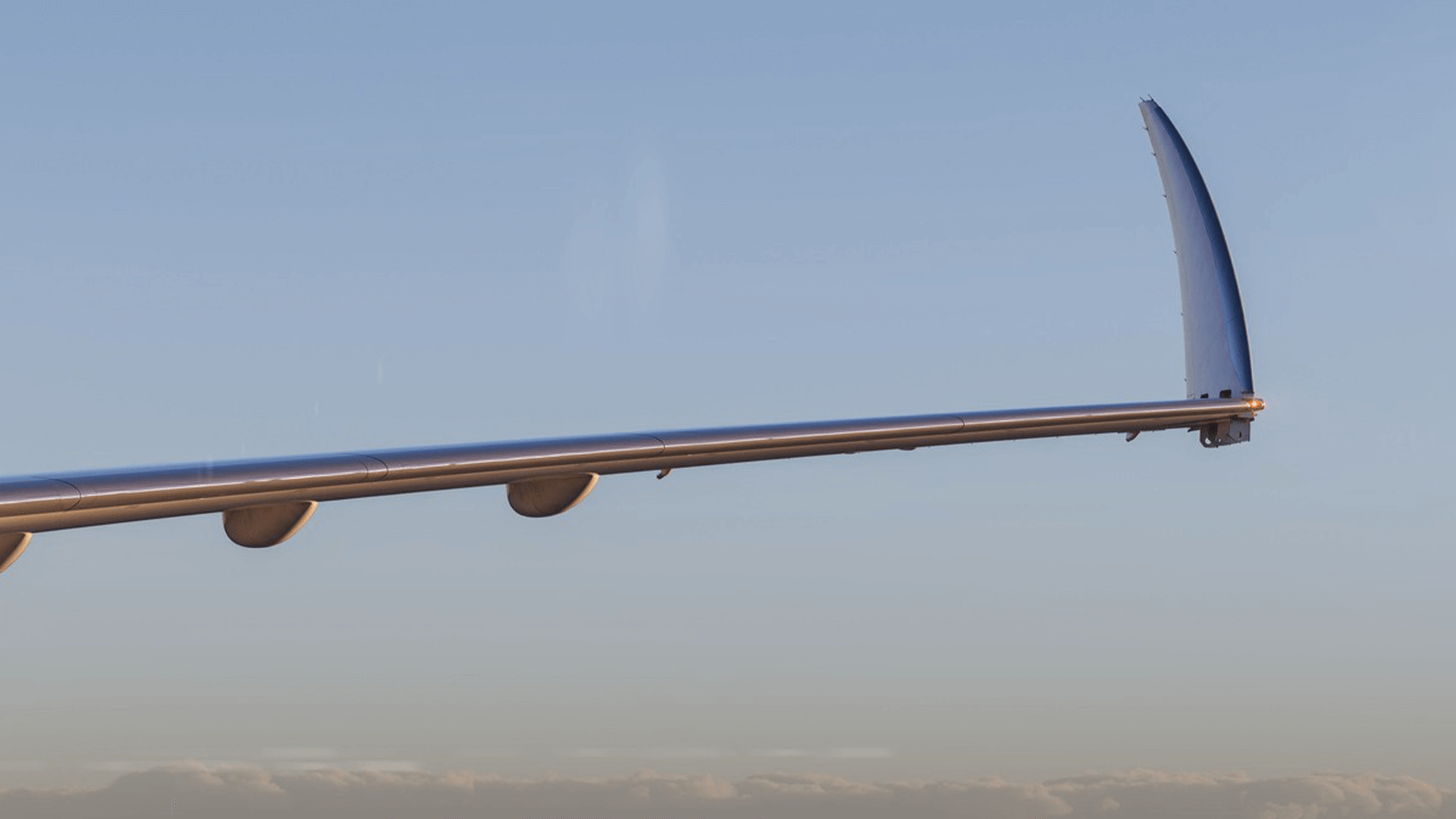

Innovative wing folding technology

Longer wings improve aerodynamics but require folding wingtips to fit standard airport gates. Liebherr provides reliable folding mechanisms for these efficient wing designs. By allowing the wings to fold, airlines can use existing infrastructure without needing to modify airport facilities, saving costs and expanding operational flexibility. In addition, wing folding can help improve ground maneuverability in congested areas, like taxiways and runways, making it a practical solution for efficient airport operations.

Lightweight thin and dry wing actuation

"Thin and dry wing actuation" refers to a type of actuator system used in aircraft wings, particularly in modern, lightweight aircraft designs. Unlike traditional systems that rely on hydraulic actuators, which are bulky and require fluid (hence "wet" systems), thin and dry actuation systems are typically electrically powered and more compact.

Benefits include:

- Weight reduction: Since these systems don't rely on hydraulic fluid, they can be significantly lighter, helping to reduce the overall weight of the aircraft, which in turn leads to better fuel efficiency.

- Simplified maintenance: Without hydraulic lines and fluid maintenance is simplified, as there’s no risk of fluid leaks or the need for fluid replacement.

- Higher efficiency: Electric actuation systems tend to be more efficient than traditional hydraulic systems, as they only use energy when needed, rather than continuously maintaining pressure in a hydraulic line.

Downloads

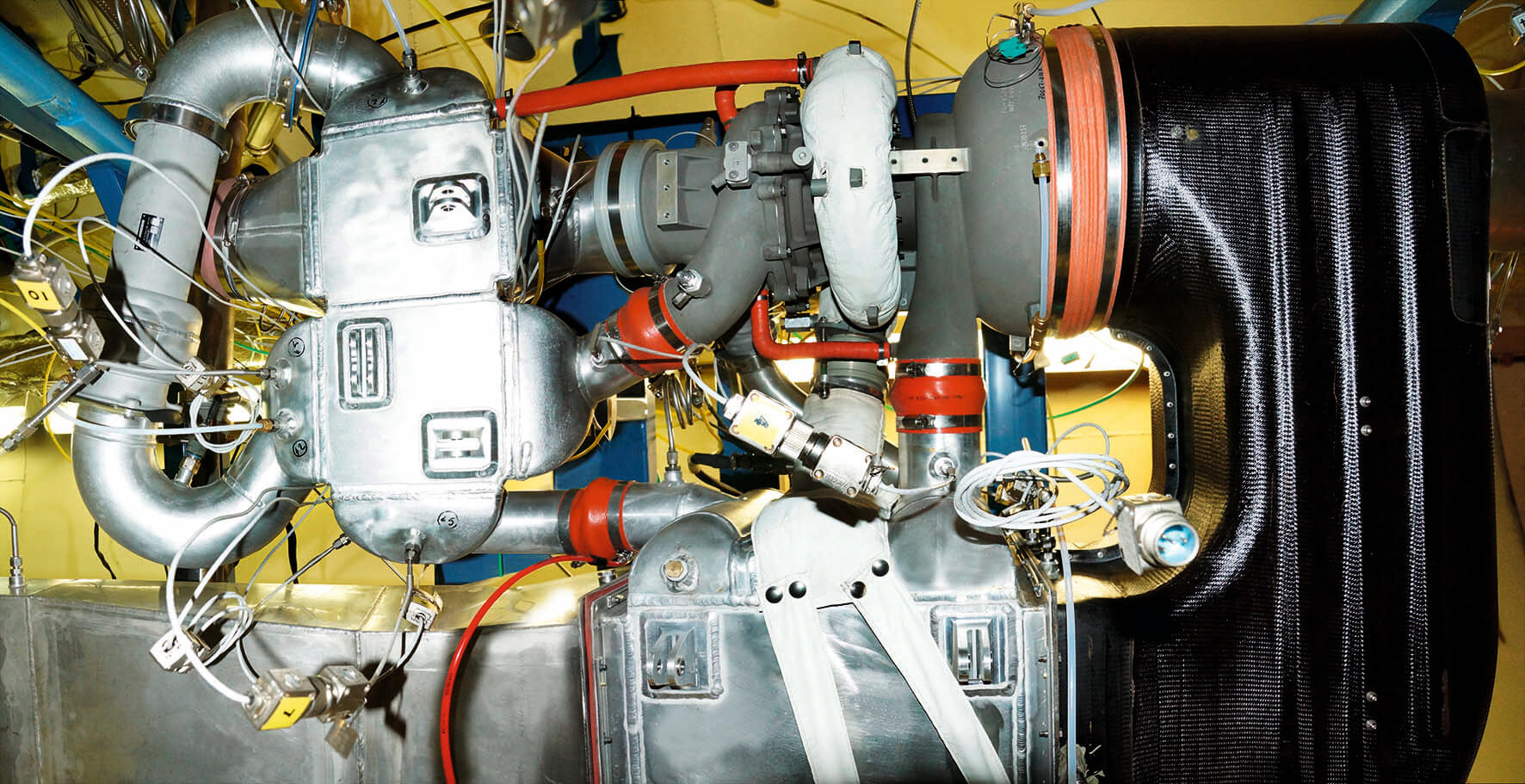

More efficient engines

More efficient engines are revolutionizing the aviation industry, offering significant benefits in terms of fuel savings, cost reduction, and environmental impact. Advanced engine technologies, such as high-bypass turbofans and geared turbofans, are designed to maximize power output while minimizing fuel consumption.

Based on its extensive know-how in the design of geared rotary actuators for high-lift systems or helicopter transmissions gearboxes, Liebherr supports engine manufacturers with design and development of power gearboxes for geared turbofan engines. The production facility in Friedrichshafen (Germany) is Liebherr’s gear competence center, mastering latest gear cutting technologies.

Less weight

Lowering an aircraft's weight is essential for improving fuel efficiency, increasing payload capacity, and reducing operational costs. Advanced materials and manufacturing techniques, like additive manufacturing, are driving significant weight reductions while maintaining strength and performance.

Additive manufacturing – laser-powered 3D printing

Additive manufacturing, often referred to as 3D printing, uses digital 3D design data to build components layer by layer from fine-powder materials, such as metals, plastics, and composites. Unlike traditional subtractive methods, which mill parts from solid blocks, this professional production process creates complex components with minimal material waste.

Examples for 3D printed products developed by Liebherr are:

- Hydraulic valve blocks

- Actuators housings

- Jet pumps

- Brackets