9 minutes

The LR 13000 in use for the first time with PowerBoom

What does it take to install four huge jack-up legs on one of the largest installation vessels in the world? The Dutch company Mammoet uses the LR 13000 for this special assignment. The crawler crane from Liebherr impresses beyond its enormous load capacities and high safety standards, through a quick and easy installation.

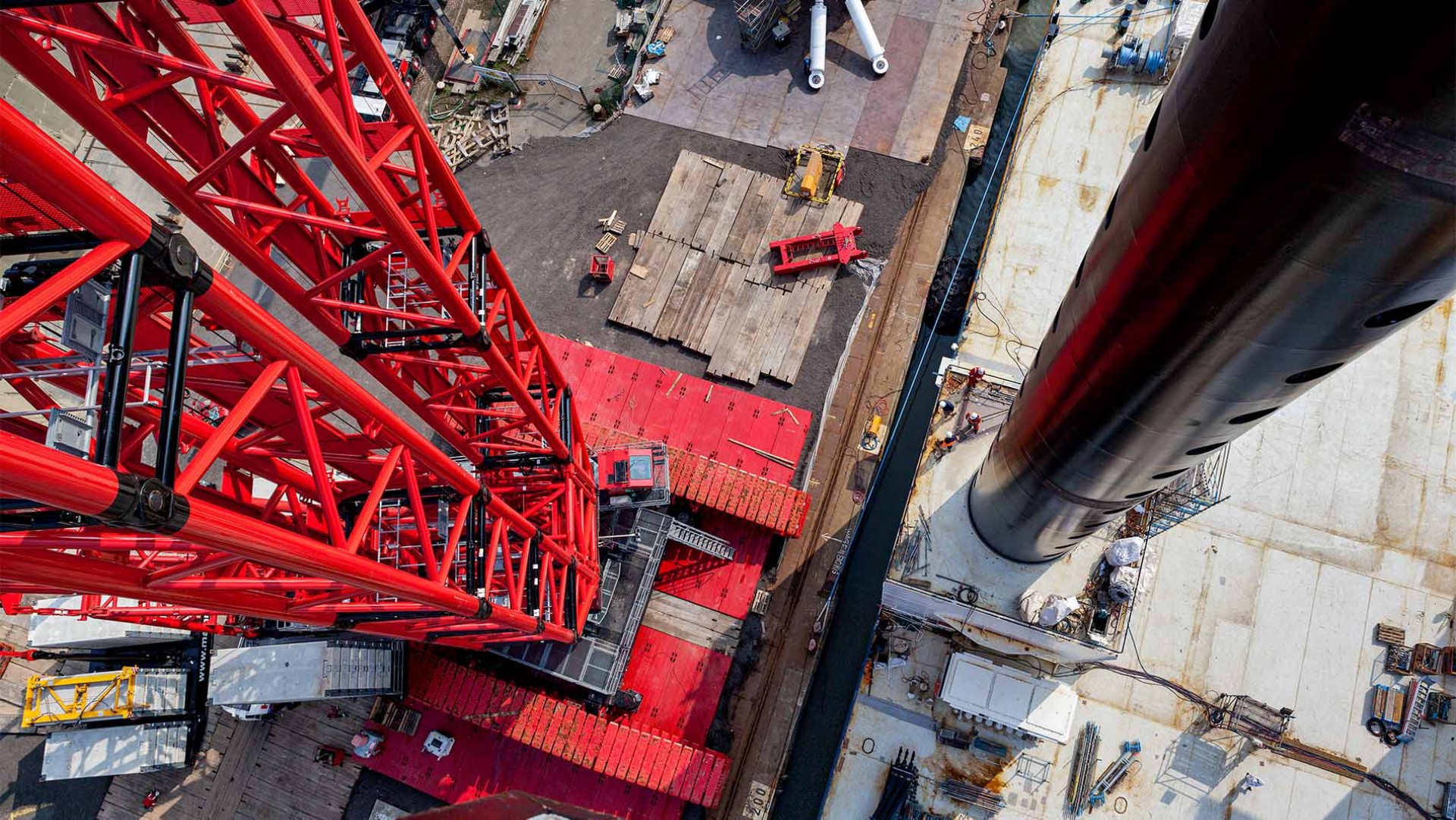

The LR 13000 in Bremerhaven

Enormous legs for Aeolus

On the 140 meter long Aeolus, a specialist vessel for the construction of offshore wind farms, four gigantic jack-up legs must be installed. To meet this challenge, the Dutch heavy load and crane specialist Mammoet calls in the LR 13000.

With a maximum lifting capacity of 3,000 tonnes, the LR 13000 is the world's most powerful conventionally designed crawler crane. For the specialist application on the Lloyd shipyard in Bremerhaven, not only enormous load capacities are required; but the work must be carried out with extreme precision.

Once completed, the Aeolus is to be lifted high above the waves of the up to 45 metres deep water. As a gigantic jack-up platform, the specialist vessel works independently of any sea state.

Along with the floating crane, the Matador 3, the LR 13000 lifts the mighty jack-up leg from the load barge.

Installation of PowerBoom for 1,000 tonne gross load

To lift the mighty jack-up legs, the LR 13000 is equipped for the first time with the PowerBoom parallel boom system. Each of the so-called jack-up legs measures 87 metres, and weighs in at 940 tonnes.

With PowerBoom the lattice boom extends over a length of 48 meters in parallel. The result: the crane gains stability and in steep boom position the load capacity values rise by around 50 percent compared to the standard boom.

Thanks to the fast set-up design of the LR 13000 and the support provided by Liebherr technicians, installation time is reduced to significantly less than the four weeks originally estimated. After just twelve days, the giant amongst the crawler cranes rises lift-ready 130 meters into the sky.

The floating crane Matador 3 moves the jack-up leg closer to the crawler crane for its erection.

Technically demanding lift

Once the crane system is in place, the powerful jack-up legs have to be installed into the large-sized hydraulic system of the installation vessel. The technically most demanding lift takes place at the beginning of the job. The first stilt has to be pushed through the structure of the heavy-load crane on the Aeolus. The lift and subsequent installation of the the giant cylinder alone takes four hours.

Along with the Matador 3 floating crane, the LR 13000 lifts the mighty steel pipe from the transport barge to align it vertically and transfer it fully. With its 65 tonne hook block and fastening equipment, the crawler crane lifts a gross load of more than 1000 tonnes here, with a reach of 23 metres.

Installing the jack-up leg

With a maximum hook height of 125 metres, lifting the jack-up leg over the high overhead cables of the ship's crane is not possible. Therefore, the steel cylinder is first swivelled on the ship's deck. With the aid of man-tall winches on deck, the Aeolus is slowly hauled. As the jack-up leg is directly over the opening, the complex insertion process begins: With large pulleys, the tube is rotated into the correct position as it is lowered.

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).Close to 1,000 tonnes in just one lift: A load, which up till now required two crawler cranes, is mastered by the LR 13000 with PowerBoom alone.

Fast set-up time and high safety standards

The Mammoet team works around the clock on the Aeolus completion. Each of the four lifts were prepared overnight, and where possible the load was attached ready. In daylight, the team, led by project manager Remco Zandstra, works on its individual installation tasks.

After the four jack-up legs of Aeolus are installed, industrial divers affix the spud cans, also known as elephant feet. These ensure that the Aeolus subsequently stands firmly on the seabed.

After just one week, all four jack-up legs of the specialist vessel are installed. An important reason behind the rapid success: the efficient installation by the LR 13000. "The crane can be set up like a larger LR 11350," explains crane operator Jouke Bruin. Project Manager Zandstra adds: "The rapid set-up time and the high safety standards indicate that Liebherr has incorporated its vast experience with crawler cranes into this machine."

Crane operator Jouke Bruin on working with the LR 13000: "It's a good thing to work with. Really nice to drive!"