L 546

Better than ever: the all-rounders

Highlights

The mid-sized wheel loaders combine performance and reliability with innovative technology. This guarantees a reliable contribution to your commercial success. The efficient hydrostatic travel drive and robust components sustainably reduce operating costs.

Generation - 8

8

Tipping load - 7,130 - 11,010 kg

7,130 - 11,010 kg

Bucket capacity - 2.60 - 7.50 m³

2.60 - 7.50 m³

Operating weight - 15,410 - 16,970 kg

15,410 - 16,970 kg

Rated output ISO 14396 / ECE-R.120 - 138 kW / 188 HP

138 kW / 188 HP

Average consumption (per operating hour) - 7.71 l/h to the consumption calculator

7.71 l/hto the consumption calculator

Availability -

What's inside

Optimised z-bar kinematics

Performance buckets

Variety of equipment

Technical data

| Linkage | Z-bar kinematics |

| Tipping load | 7,130 - 11,010 kg |

| Bucket capacity | 2.60 - 7.50 m³ |

| Specific bulk weight of material | 0.50 - 1.80 t/m³ |

| Operating weight | 15,410 - 16,970 kg |

| Output ISO 9249 / SAE J1349 | 148 kW / 201 HP |

| Rated output ISO 14396 / ECE-R.120 | 138 kW / 188 HP |

| Emission stage | V |

Downloads

Videos

Image video L 526 - L 546 G8

Hydraulic quick coupler Solidlink

Active personal detection system

Animation Liebherr weighing device with "Truck Payload Assist"

Automatic bucket functions

Skyview 360°

Assistance systems

Adaptive working lighting

Active personnel detection at the rear

Roof camera for front area monitoring

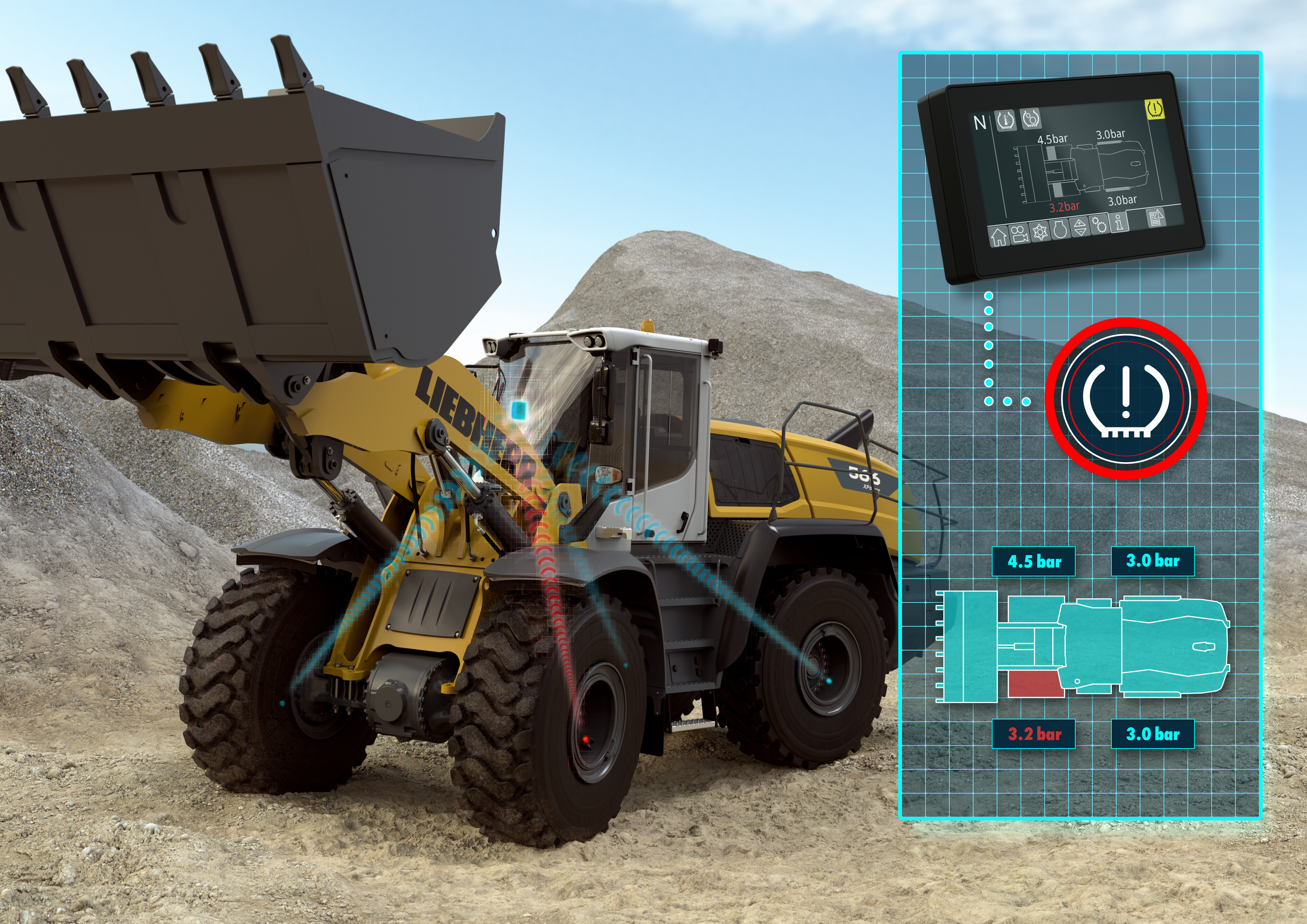

Integral tyre pressure monitoring system

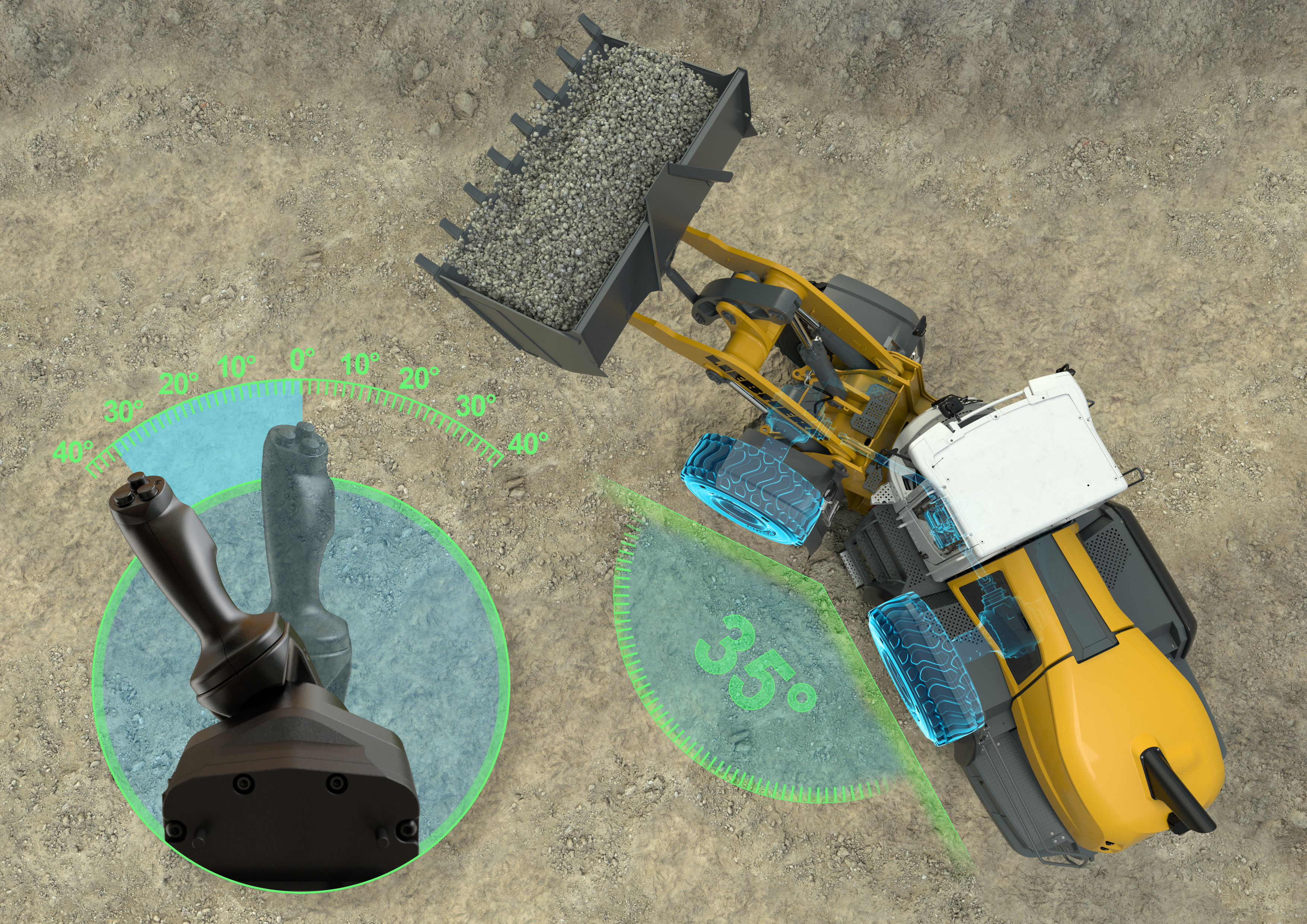

Joystick steering

Operator's cab without steering wheel / steering column – joystick steering only

Solidlink

Skyview 360°

Liebherr weighing system with "Truck Payload Assist"

Consumption calculator

Enter the data for your machine and calculate your own savings!

- Litres per operating hour

- 7.71 l/h

- Total operating hours of all machines

- 56’900.82 h

Average fuel consumption

Operating hours per year

Fuel price in €/l