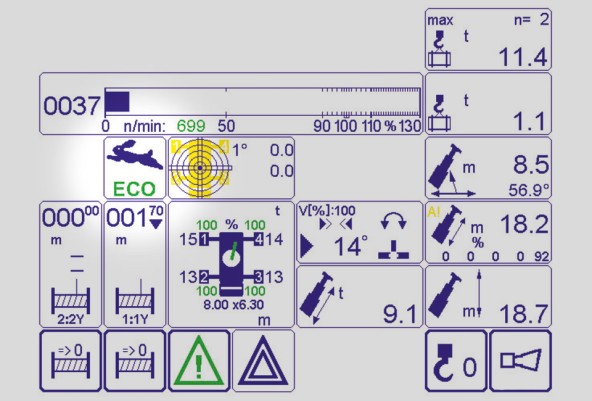

Perfectly designed: Low cost crane operation

Total efficiency in action.

Lower fuel consumption + less noise = ECOmode

On our mobile cranes which have a load sensing control system, the crane operator enters the required operating speed using the master switch – using ECOmode. The perfect engine speed is calculated by the LICCON 2 control system and set on the crane's engine by the engine management system. Successful:

- Up to 10 % lower fuel consumption

- Lower noise emissions