10 minutes - magazine 01 | 2024

A dozen for the energy transition

A dozen Liebherr mobile cranes working together – what a picture!

A dozen for the energy transition

A dozen Liebherr mobile cranes working together – what a picture!

Group work among Liebherr mobile cranes

The twelve mobile cranes with load capacities of between 90 tonnes and 400 tonnes lifted a one-kilometre-long pipeline to position it correctly for insertion into the ground. The pipeline is part of the district heating network in the Netherlands, which is currently being expanded.

Richard Rijbroek - Environmental manager at Denys

There are a wide variety of measures, options and ideas on how countries can reduce emissions and drive forward the energy transition. The European Climate Law commits the EU to becoming climate-neutral by 2050. The Dutch government has therefore decided to switch heating systems for private households and businesses from natural gas to sustainable energy sources such as district heating or electric heat pumps. To achieve this, the district heating network in the Netherlands must be expanded.

Richard Rijbroek is an environmental manager at Denys and supervised the construction of the pipeline in Delft. The client is Nederlandse Gasunie NV. Rijbroek explains: “Preparations for the “WarmtelinQ” project have been underway for 3 years. We will use the residual heat from industry in the port of Rotterdam and from waste incineration plants to heat homes and businesses in South Holland.” The pipeline runs from the port of Rotterdam to The Hague via Vlaardingen.

The pipeline goes into the ground, runs under a watercourse at a depth of around 30 metres and comes back to the surface in Delft, 1 kilometre away.

A motorway stands in the way

A drill head was installed on one side of the 1,000-metrelong district heating pipeline, as Harm van Dijk, project manager of the Dutch crane operator Boer B.V., explains: “We are drilling a bore here for the heating network. The pipeline is drilled into the ground.” To do this, the pipeline has to be lifted up and placed in a certain curve so that it is drilled into the ground at a defined angle. According to van Dijk, the length of the retractable arch is 275 metres: “To get the exact curvature, we form the arch with ten cranes. Each of these cranes lifts 18 tonnes. For this reason, we need cranes with a capacity of 90 – 140 tonnes here. On the other side of the motorway, we used a 300-tonne and a 400-tonne crane because of the large radius over the motorway.” The kilometre-long pipeline cannot be completely pre-assembled on the ground, as a motorway and a bridge cross the route. It was therefore stored on containers at a sufficient height as required.

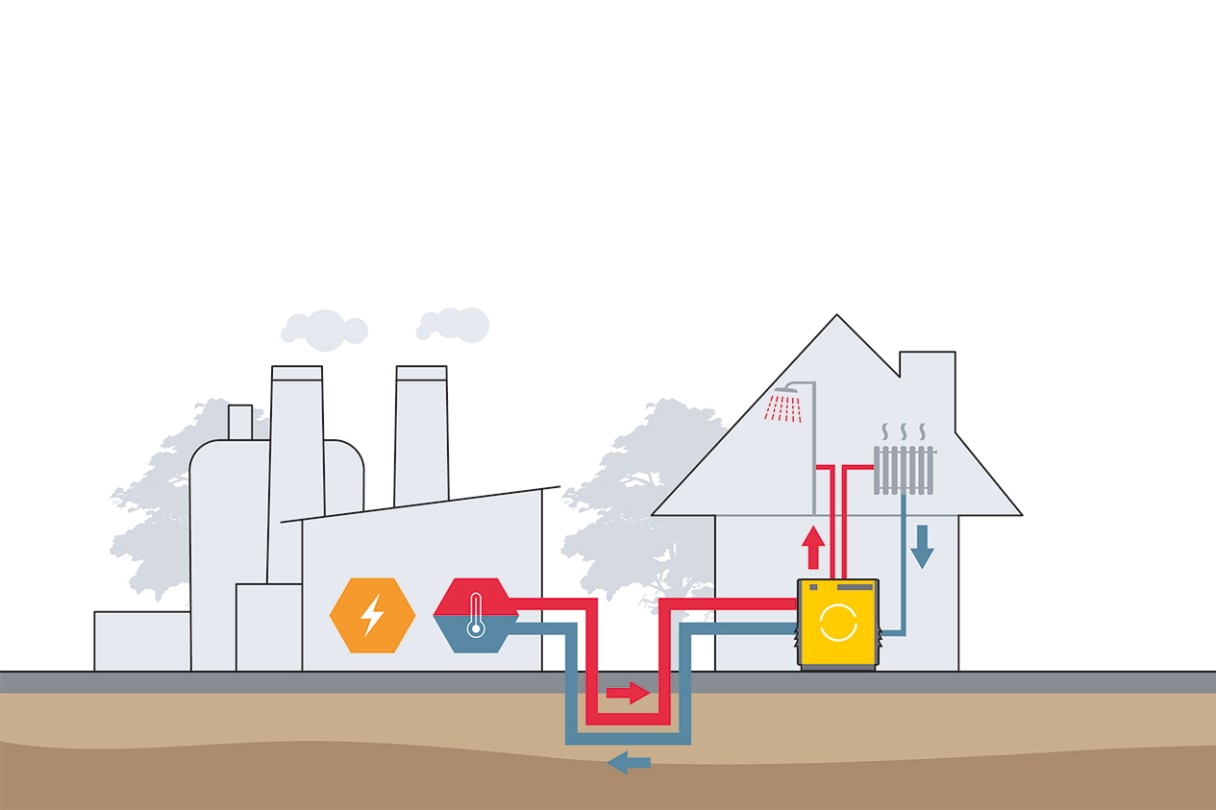

How does district heating work?

- In the case of district heating, the heat is mainly obtained as a by-product of power stations or waste incineration plants.

- The heat is fed into a distribution network of highly insulated pipes in the form of hot water and is mainly used for private households.

- Depending on the origin of the heat, district heating is considered sustainable heat generation and helps to reduce CO₂ emissions.

A dozen for the energy transition

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Data protection settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).The pipeline must be drilled into the earth at a certain angle. To do this, we form an arch with ten cranes.

Van Dijk reports: “In the run-up to a job like this, thorough preparation is necessary. We create our work plans using AutoCad and the LICCON CranePlanner to determine the required capacity of the cranes. This job was special, firstly because the pipeline is very heavy and secondly because of its proximity to the motorway.”

Harm van Dijk - Project manager of Boer B.V.

The pipeline, which is 1 kilometre long in total, has an outer diameter of 90 centimetres, weighs 500 kilograms per metre and weighs a total of 500 tonnes. “Our company prefers to work with Liebherr cranes,” adds Van Dijk. “The main reason for us is that the machines are reliable and of good quality. Liebherr also offers good customer service.”

This article was published in the UpLoad magazine 01 | 2024.