Click RELEASE VIDEO and follow the data protection notices.

Next-level efficiency

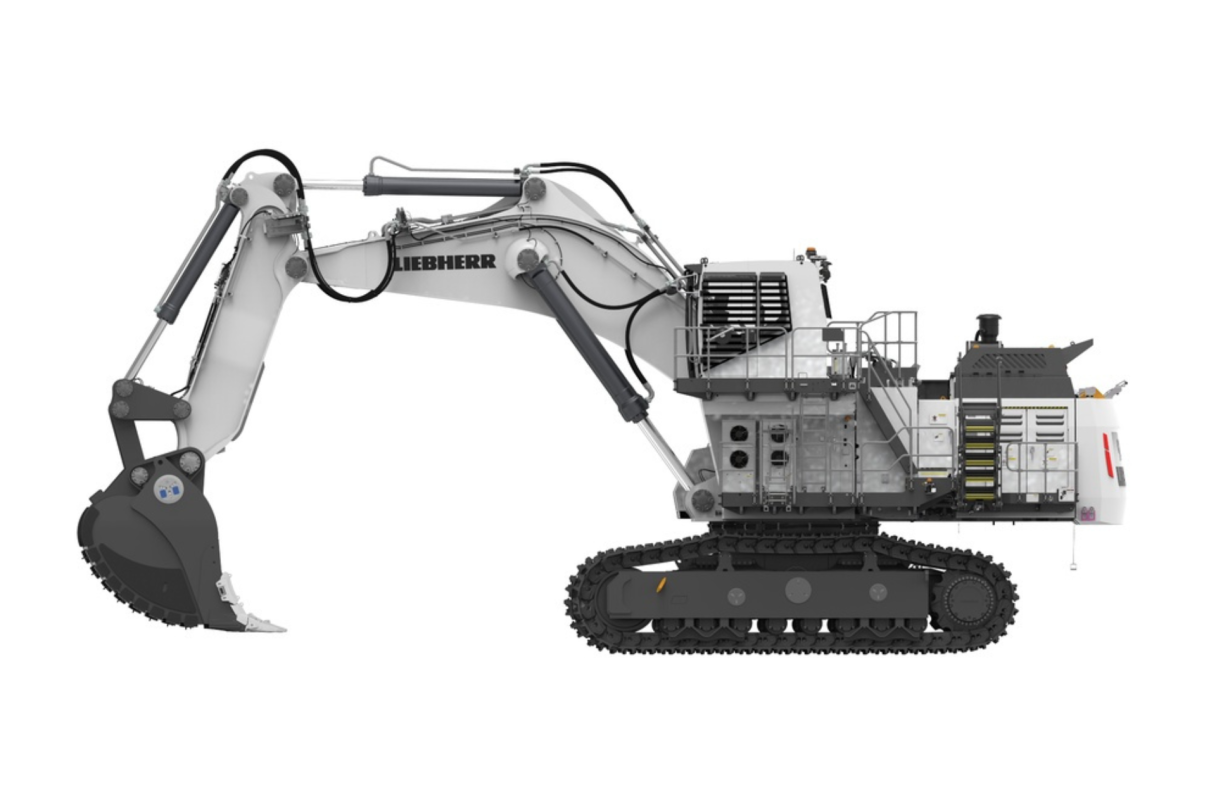

The R 9300 is the second Generation 8 excavator launched within Liebherr’s product portfolio and builds on the original equipment manufacturer’s (OEM’s) decades of excavator design expertise in the mining industry. As a Generation 8 machine, the R 9300 comes fitted with the most advanced Liebherr mining technologies. These technologies provide increased operational performance and enable future product requirements such as automation and zero emission options.

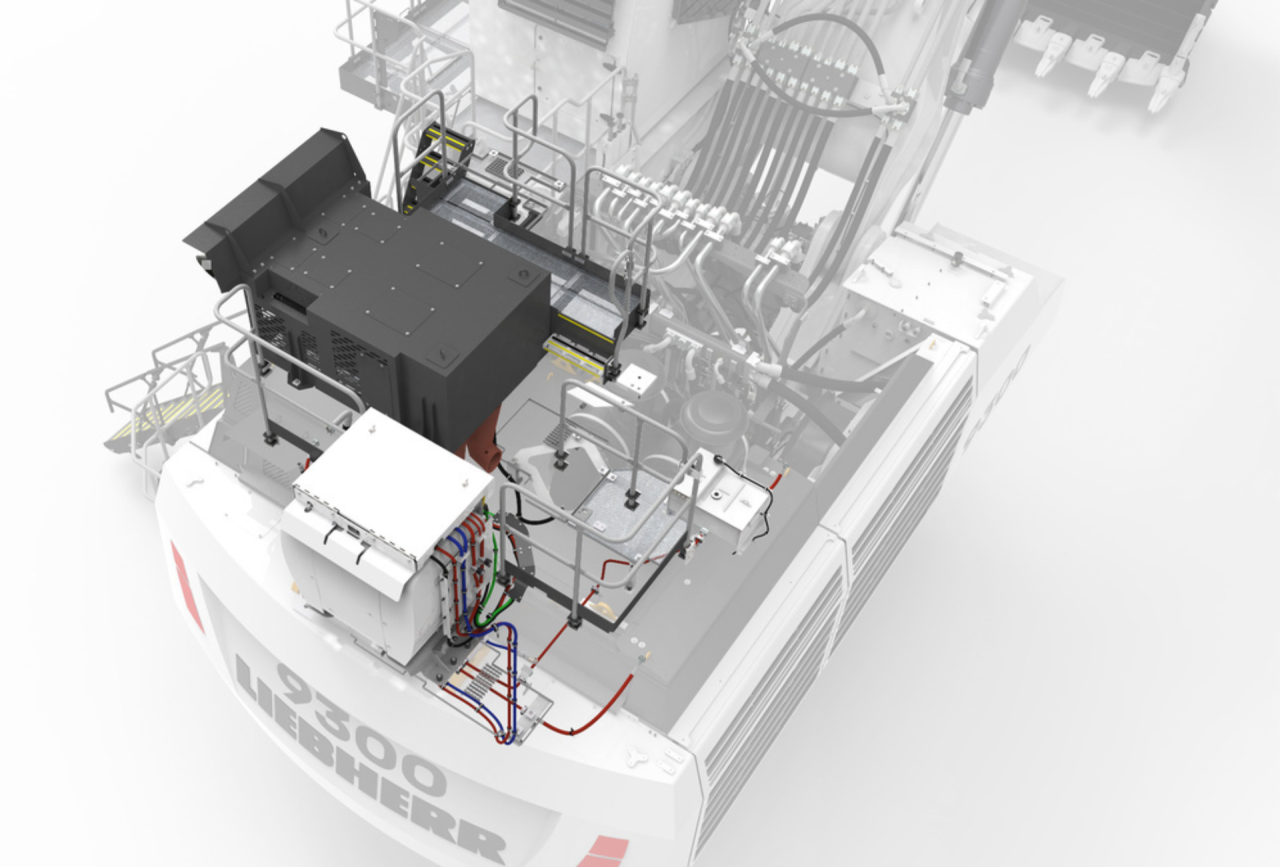

The R 9300 was also designed to support greenhouse gas emission reduction targets. Liebherr’s proprietary engine and hydraulic management system – Liebherr Power Efficiency – comes as standard to reduce onsite fuel consumption. Further, the R 9300’s diesel engines are Tier 4 and Stage V compliant to adhere to strict international emissions standards and an electric power train is already in development.

Move more material using less fuel

Fuel efficiency

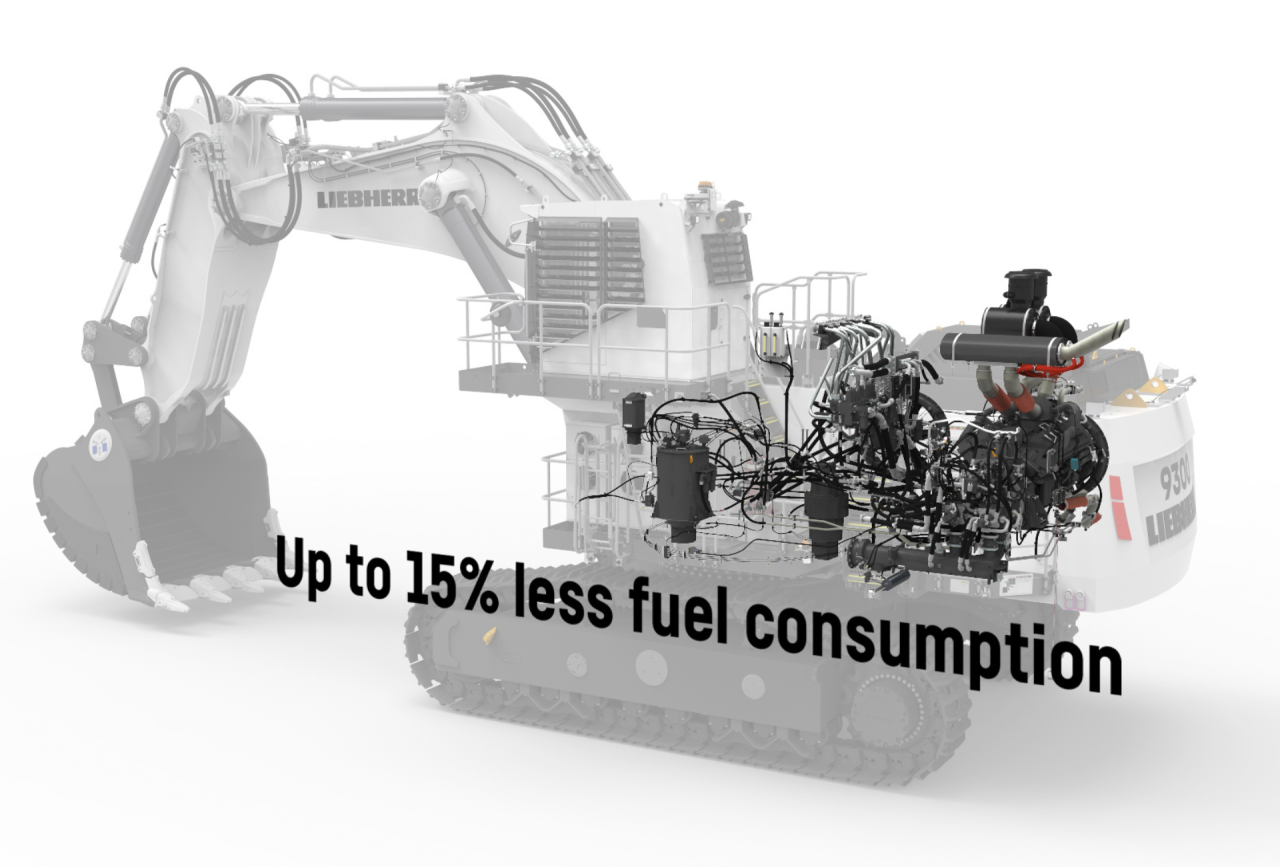

The R 9300 gets the most out of each fuel drop thanks to its unique hydraulic design combined with the Liebherr Power Efficiency system.

Fuel consumption

The R 9300 achieves 15% less fuel consumption than Liebherr’s previous model, thanks to Liebherr’s proprietary engine and hydraulic management system, Liebherr Power Efficiency.

Productivity

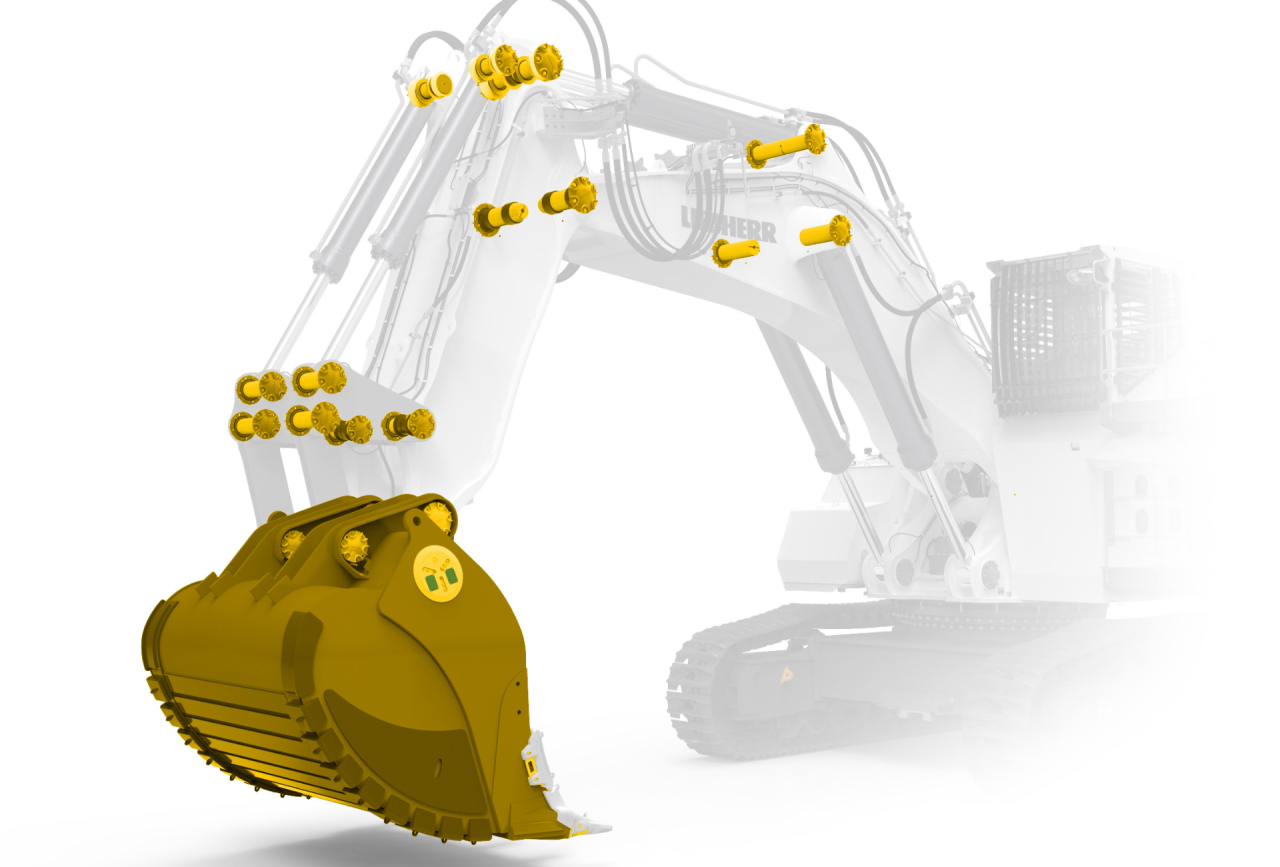

Higher productivity is the result of the R 9300’s lighter and stronger attachment, larger bucket capacity, optimal forces distribution, and fast cycle times.

Cost per tonne

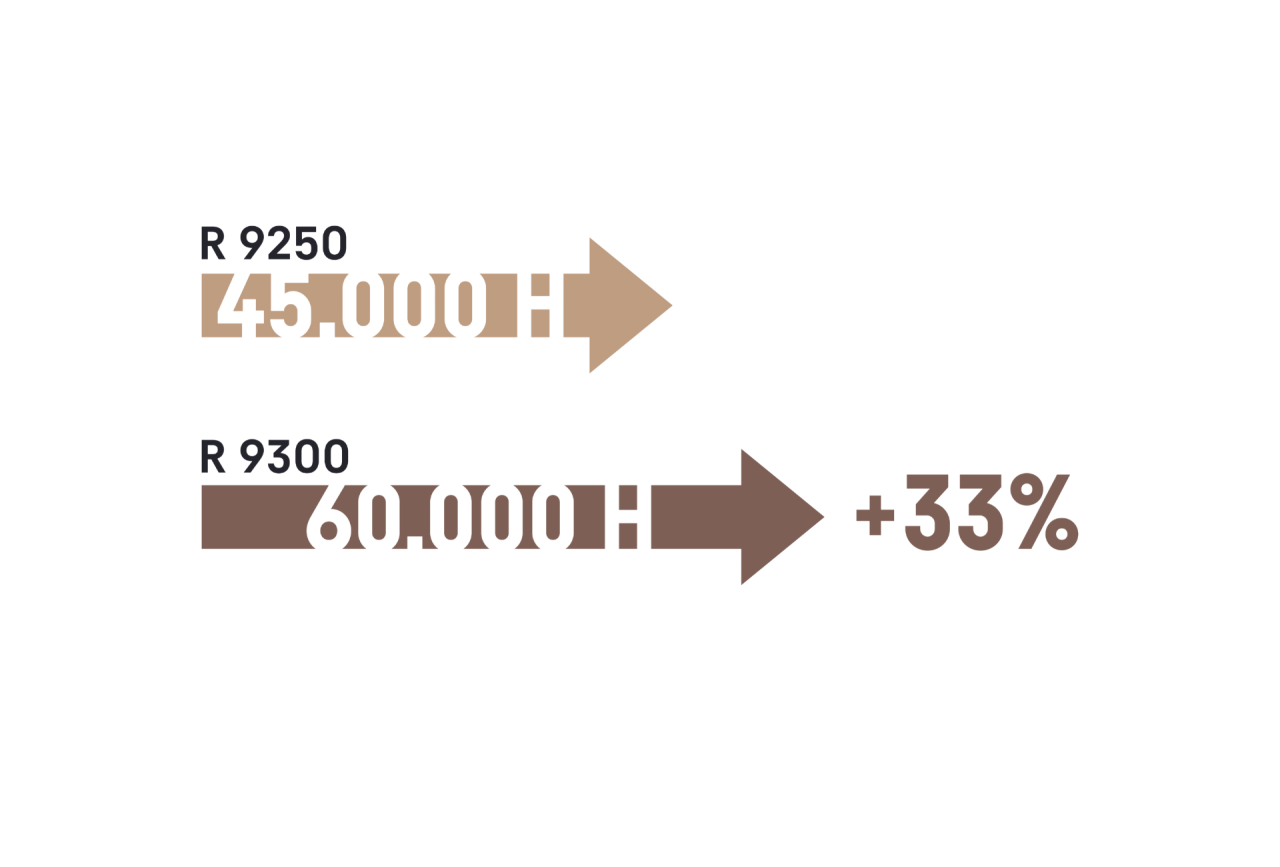

The cost per tonne of the R 9300 is significantly reduced compared to R 9250, thanks to its optimised life cycle costs, vastly reduced fuel consumption, and better productivity.

Read the R 9300's Job report!

Discover the proven results about its onsite productivity, reliability, and fuel efficiency.

Design principles

The R 9300 replaces the R 9250 excavator in the 250-tonne class and encompasses Liebherr’s most advanced design principles and technology platforms to further enhance the performance, efficiency, and safety of the machine.

Operating weight

Backhoe (BH): 252 tonnes / 278 tons

Face shovel (FS): 253 tonnes / 279 tons

Powertrain

Engine power (SAE J1995):

1,007 kW (1,350 hp) at 1,800 rpm

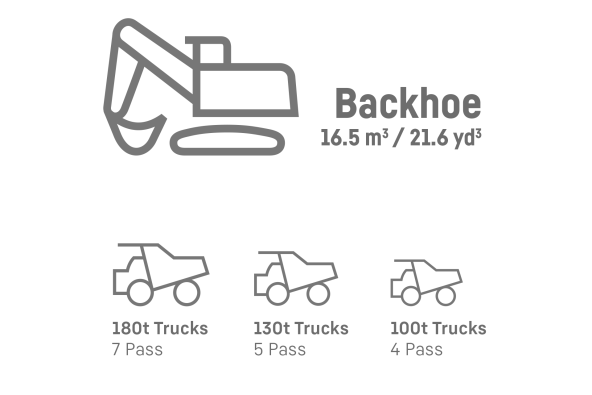

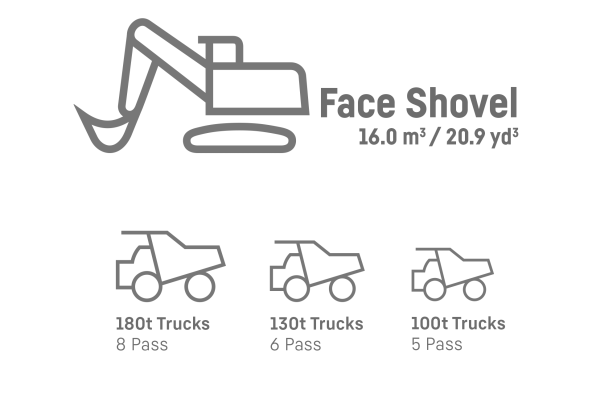

Bucket capacity

Backhoe (BH): 16.5 m3 / 21.58 yd3

Face shovel (FS): 16.0 m3 / 20.93 yd3

Forces

Breakout force (BH/FS): 885 kN/980 kN

Digging force (BH): 810 kN

Crowd force (FS): 1,265 kN

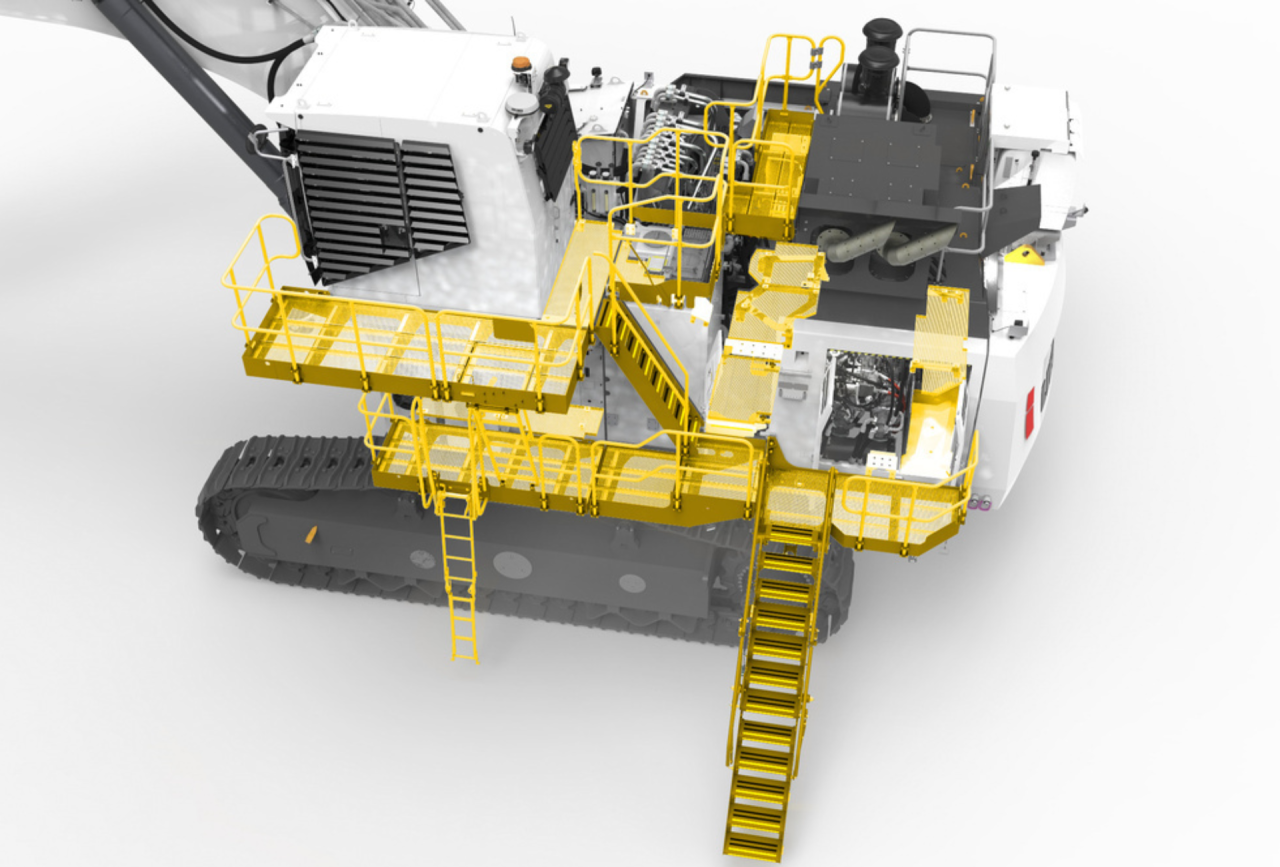

Machine tour

Click or tap on the yellow dots to learn more about our new R 9300.

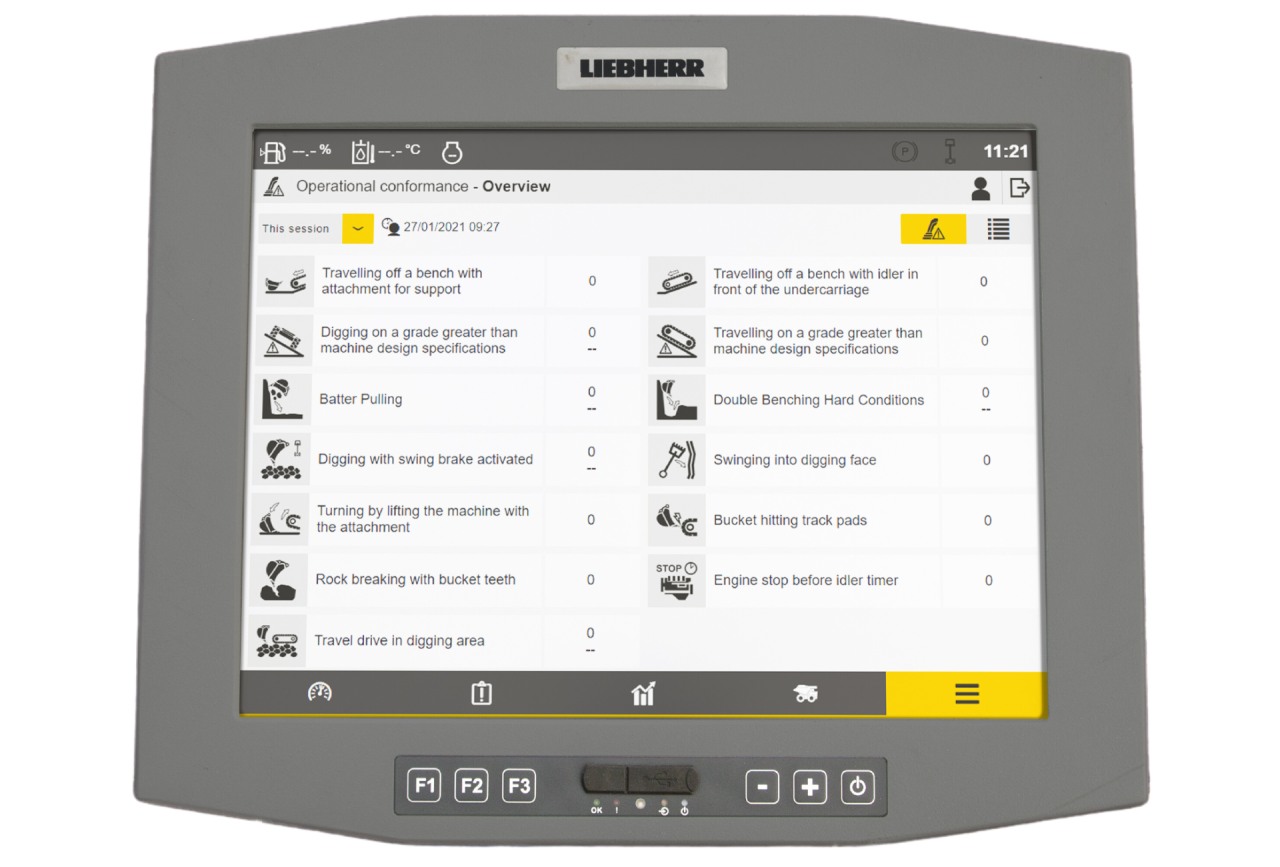

Latest cabin generation

The cabin in the R 9300 comes with enhanced ergonomics, large touch screens, and a new and improved control panel design.

Click or tap on the yellow dots to discover features of Liebherr’s latest cabin generation.

Shovel truck match

Need more technical data?

Watch how the R 9300 was assembled on site for PT Karunia Armada Indonesia!

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Data protection settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).Want to hear more about the new R 9300?

Find your local dealer today!

By clicking on “ACCEPT”, you consent to the data transmission to Google for this map pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each Google map individually in the future and want to be able to load them without this blocker, you can also select “Always accept Google Maps” and thus also consent to the respectively associated data transmissions to Google for all other Google maps that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Data protection settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and thr Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).