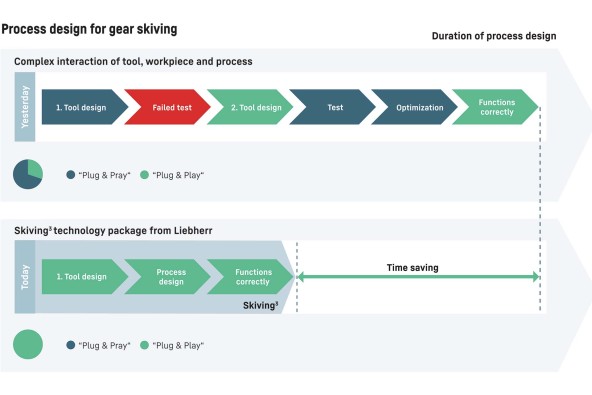

From “Plug & Pray” to “Plug & Play”

Gear skiving used to be a gear cutting method that was difficult to control due to its complex kinematics, but it now offers a genuine alternative to shaping or broaching. The synergy between machines, tools and processes provided by Liebherr-Verzahntechnik GmbH’s Skiving³ technology package makes it possible to efficiently and flexibly machine an extremely wide variety of workpieces, including in small batch sizes. Skiving³ therefore crucially boosts productivity, quality and cost-effectiveness levels not just in series production, but in contract gear manufacturing as well.

Gear skiving is a continuous rotary gear cutting method in which the workpiece and tool are arranged at a cross-axis angle. Not only does this provide higher degrees of freedom when machining, it is also productive and cost-effective. Skiving is suitable for an extremely wide variety of workpieces – for large and small gears, external and internal gears, and workpieces with interference contours. However, skiving’s complex process kinematics impeded its popularity for some time. Haider Arroum is the Head of Sales for gear cutting tools at Liebherr-Verzahntechnik GmbH and recalls that “gear skiving used to be a tedious and repetitive process that was prone to errors and it was wise to avoid making further changes to the machine once configured, if at all possible.” However, modern machines with direct drives, new tool materials and intelligent simulations have led to a renaissance for skiving in recent years.

Gear skiving: productive and cost-effective

Liebherr-Verzahntechnik GmbH is a pioneer in this sector and offers users the expertise they require through the Skiving³ technology package (“Cubic Skiving”). After all, successful gear skiving is built on the synergy between machines, tools and processes. The company is also increasingly turning to gear skiving instead of shaping in its own contract manufacturing work, such as spline, or mating gear production applications. “As a result of skiving, our manufacturing rates are much faster and we are providing a higher standard of quality and deliverability while also boosting output and reducing prices,” reports Marcel Sobczyk, a gear cutting tool applications expert at Liebherr-Verzahntechnik.

Series production and small batch sizes

Skiving³ is the key to successful gear skiving

Service is also a priority: “We are not simply a supplier. We provide assistance to our customers on all matters as a skilled partner. This is particularly vital for job shops,” explains Marcel Sobczyk. Haider Arroum concludes: “With Skiving³, we have drastically simplified gear skiving. Having shifted from ‘Plug & Pray’ to ‘Plug & Play’, it’s now simple and practical even for smaller batch sizes!”