LGG 300 - 500 / 700 M

The allrounder.

Highlights

Machine length - 3,500 mm

3,500 mm

Machine width - 2,700 mm

2,700 mm

Machine height - 4,000 mm

4,000 mm

Workpiece diameter - 300 - 700 mm

300 - 700 mm

Axial travel - 1,000 mm

1,000 mm

Shift distance - 230 - 350 mm

230 - 350 mm

Min. position above table - 60 mm

60 mm

Grinding head swivel angle - 45 °

45 °

Workpiece speed - 1,000 min-1

1,000 min-1

Flexibility

Technological diversity

Powerful

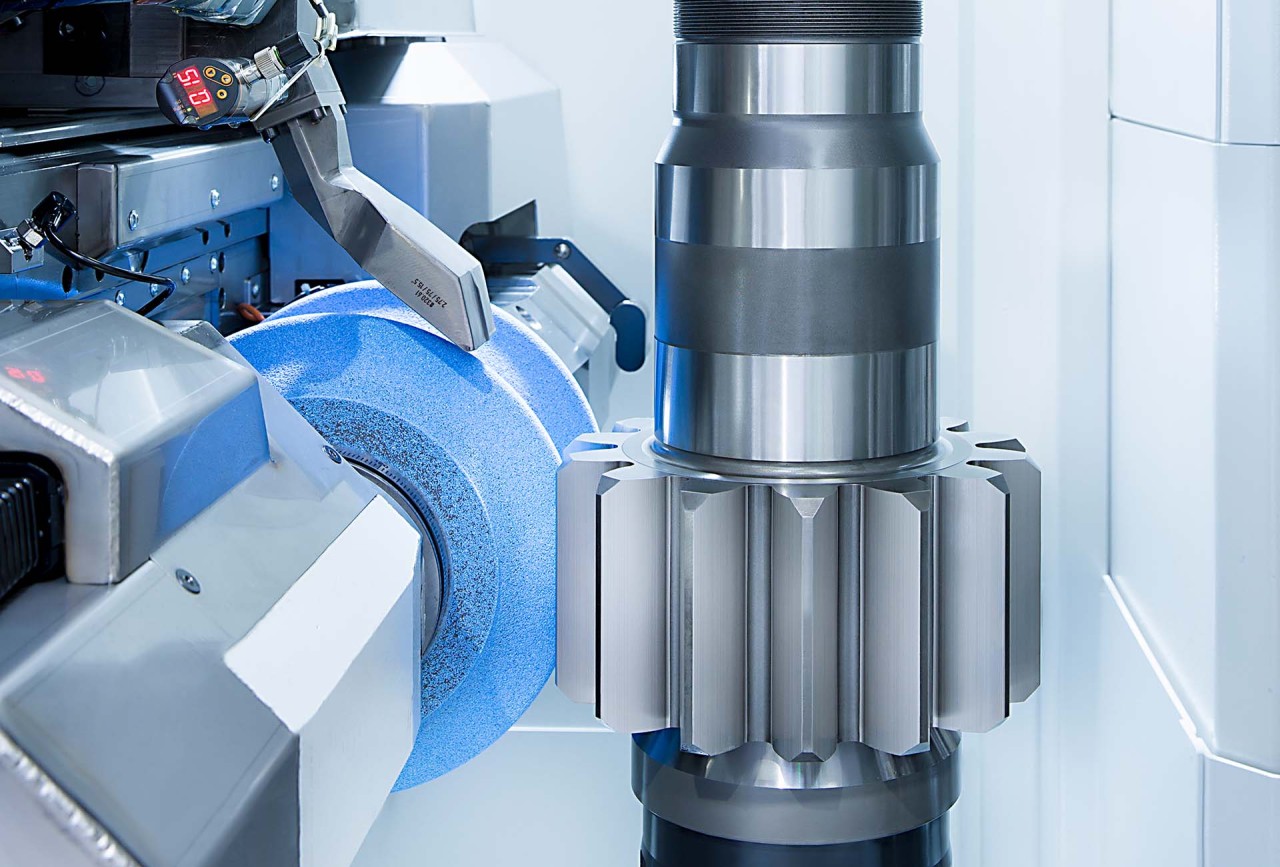

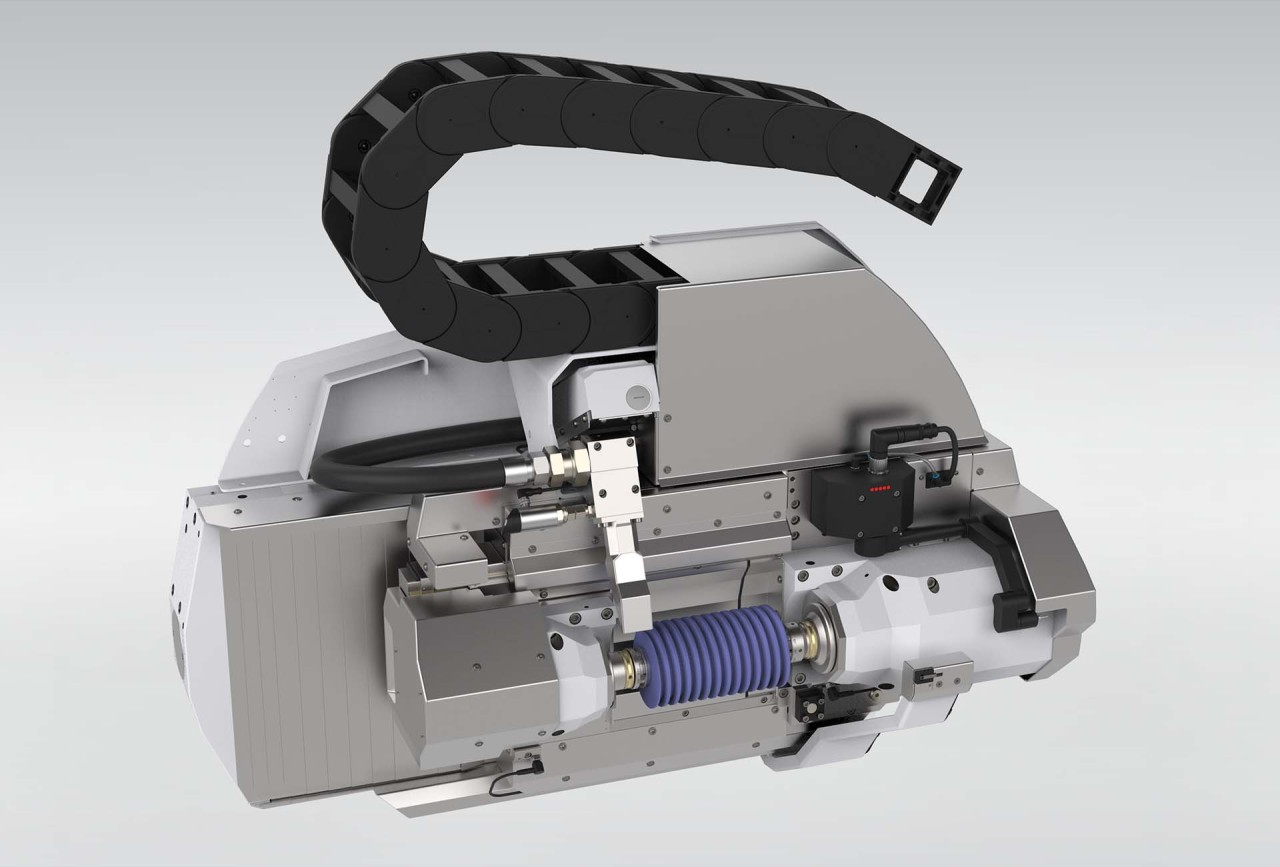

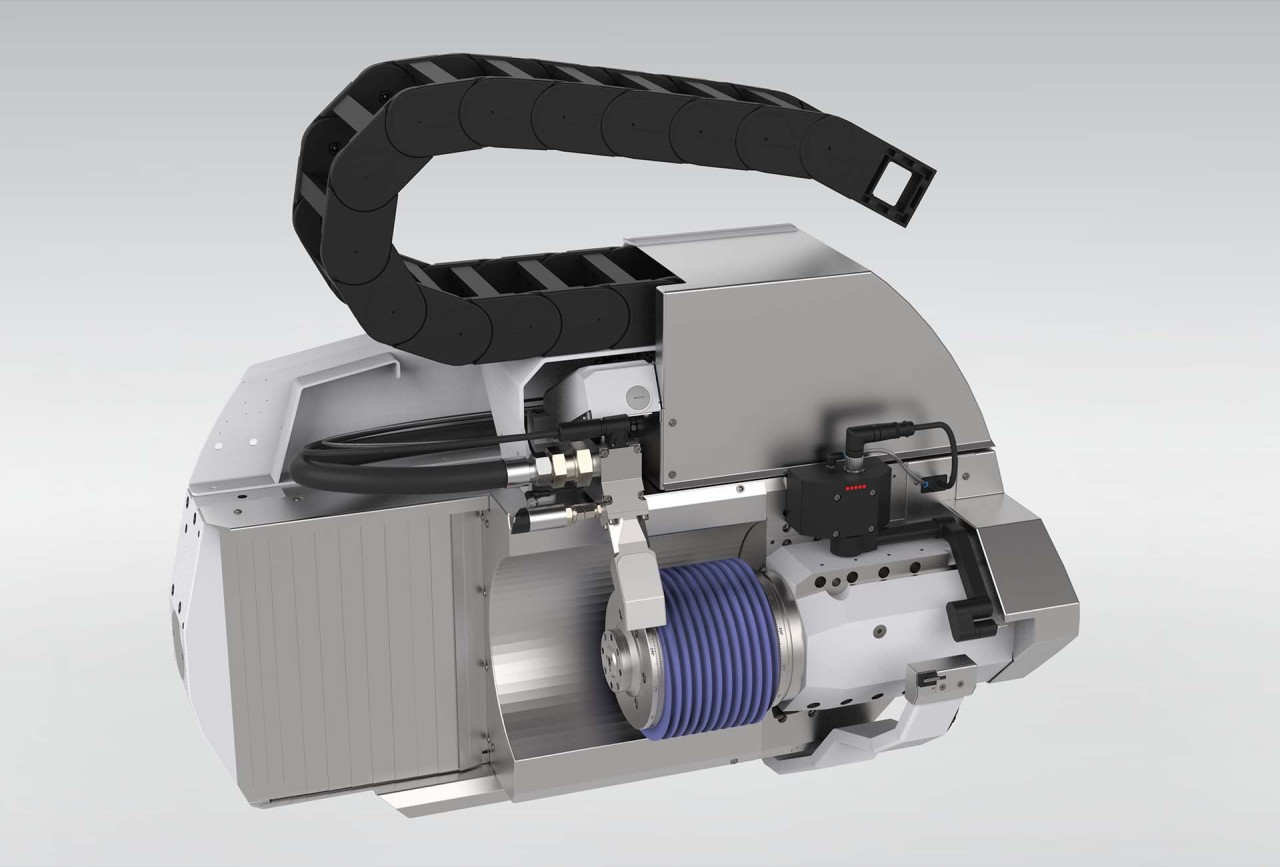

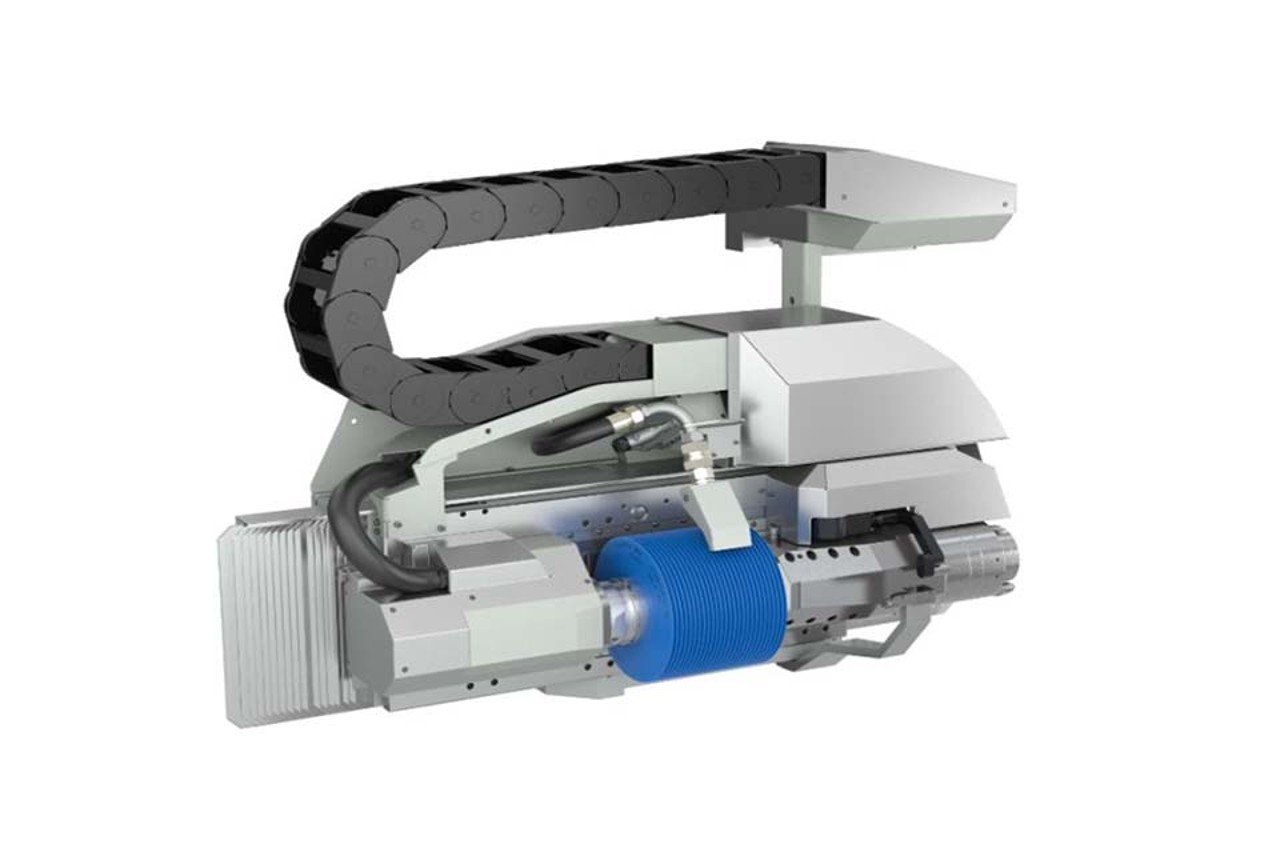

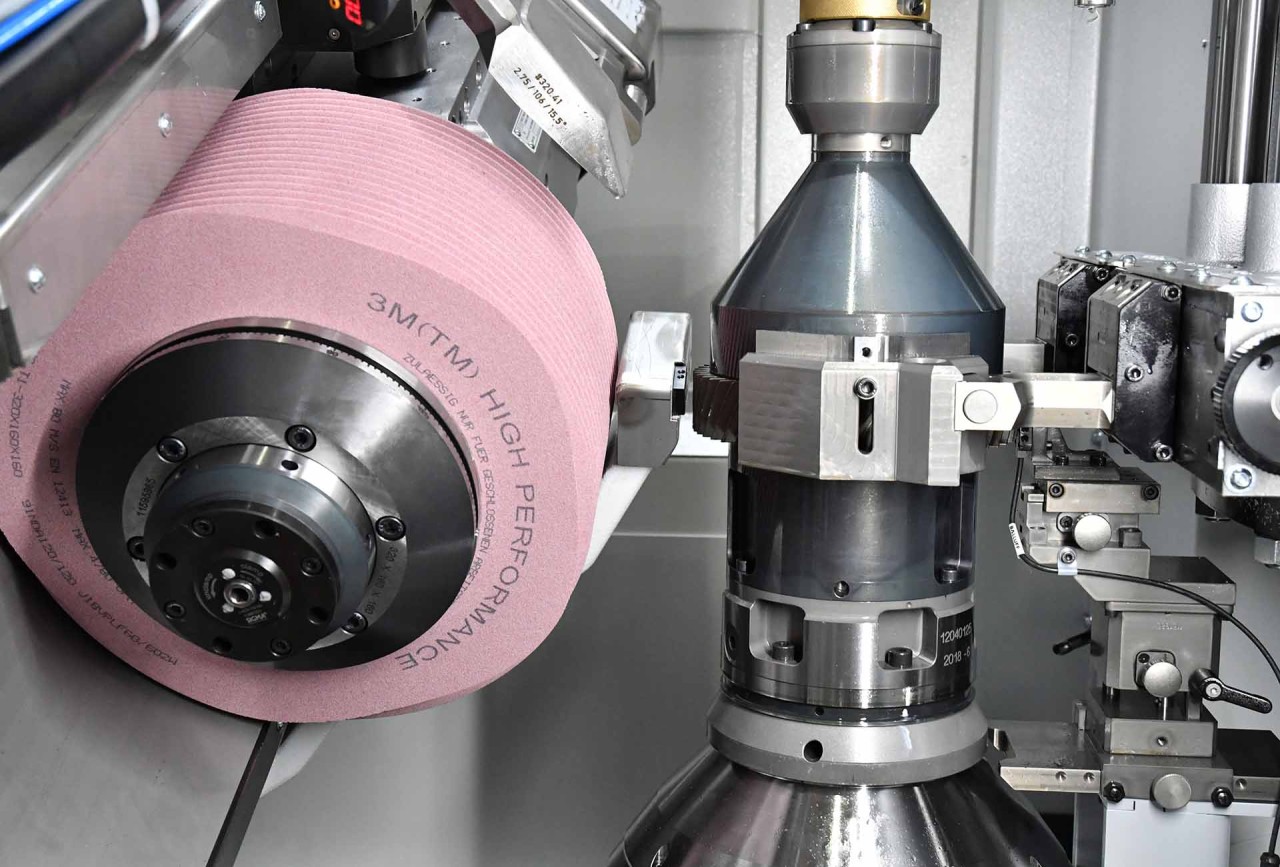

External and internal grinding heads

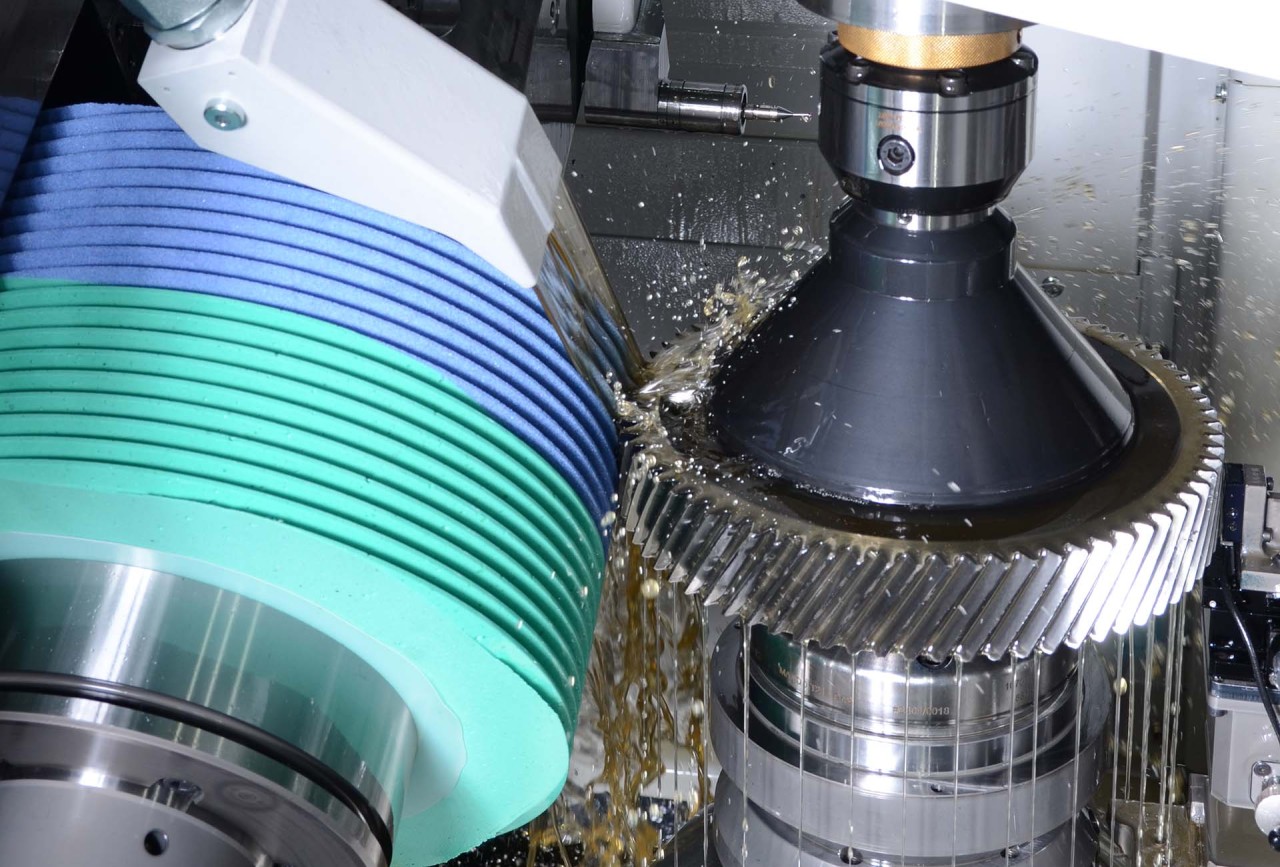

Process-optimized external grinding heads and internal grinding arms are available for the LGG. Balancing systems inside the spindle are used in both external grinding heads (GH 320 and GH 240 CB). On the GH 320 CB, the balancing system is integrated in the arbor.

High drive power and speeds are major advantages – for example, when using new grinding materials. The modern tool holding makes it possible to replace the grinding arbor quickly and easily.

Small grinding tool diameters are available for collision-critical workpieces and for special tooth corrections.

With the GH 320 CB grinding head, it is now also possible to efficiently grind optimal-quality workpieces up to module 14 mm.

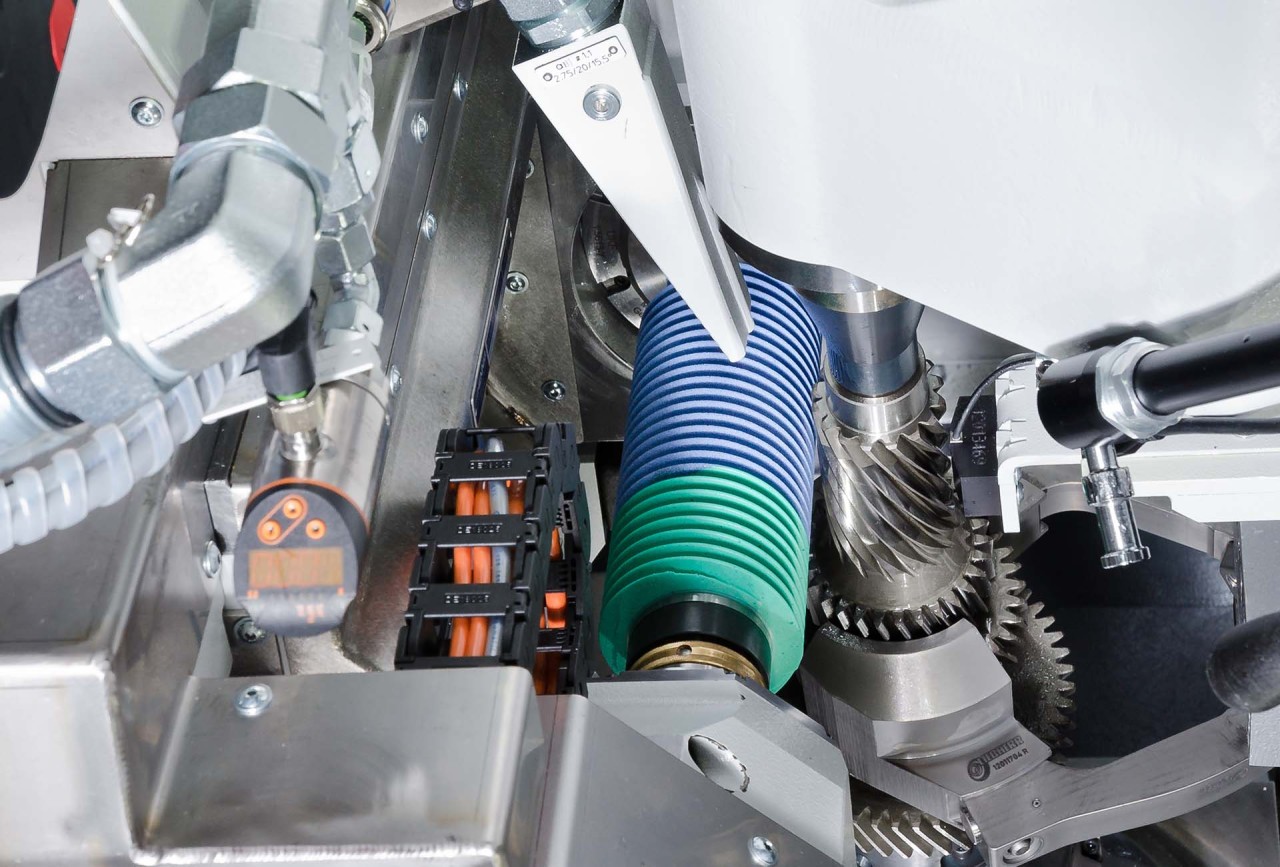

Fast and easy changeover

The adaptable internal grinding arms can be mounted quickly and easily on the external grinding head and are driven using the main drive. Other grinding heads can be provided on request.

In only 30minutes from external to internal grinding

Video

Generating grinding planetary gears, module 14, on the LGG 500 generating and profile grinding machine

Inline process monitoring

Technology

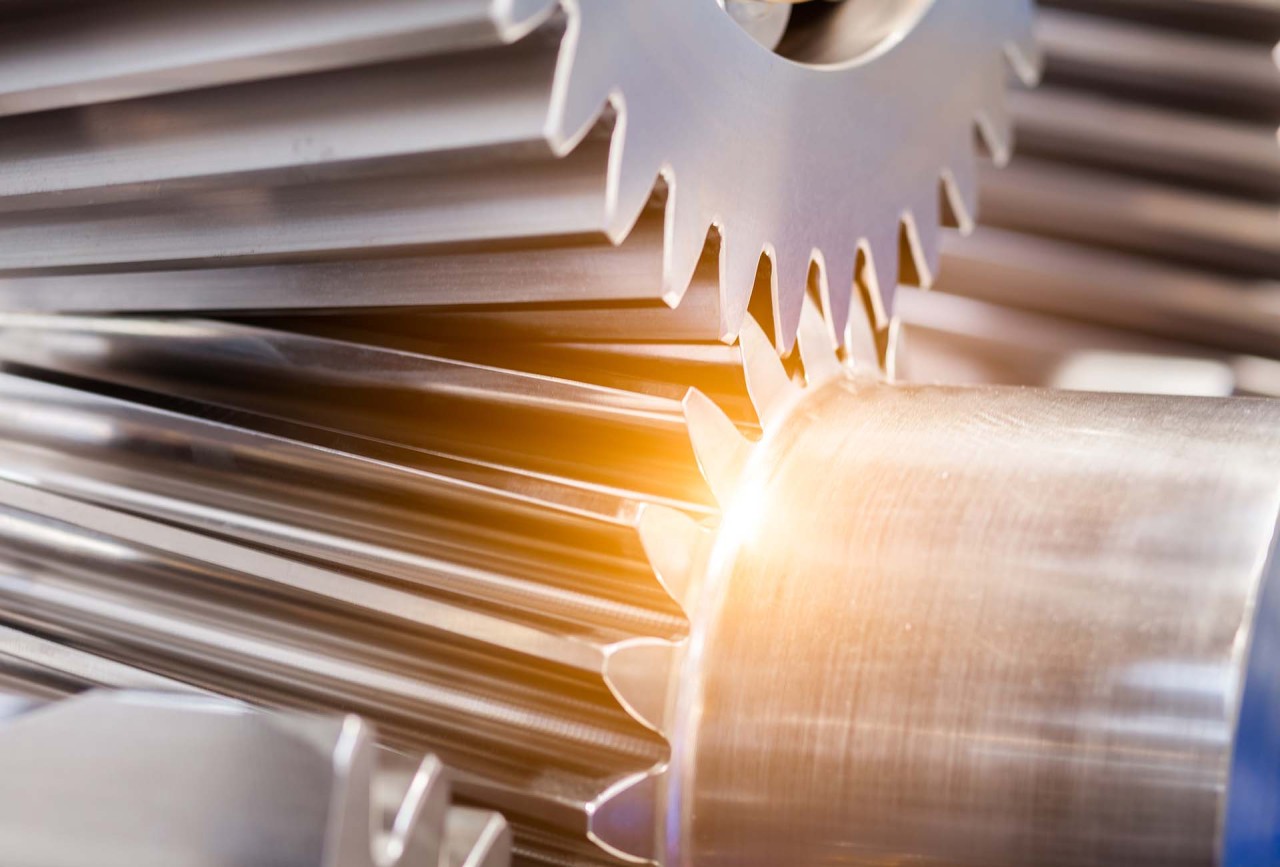

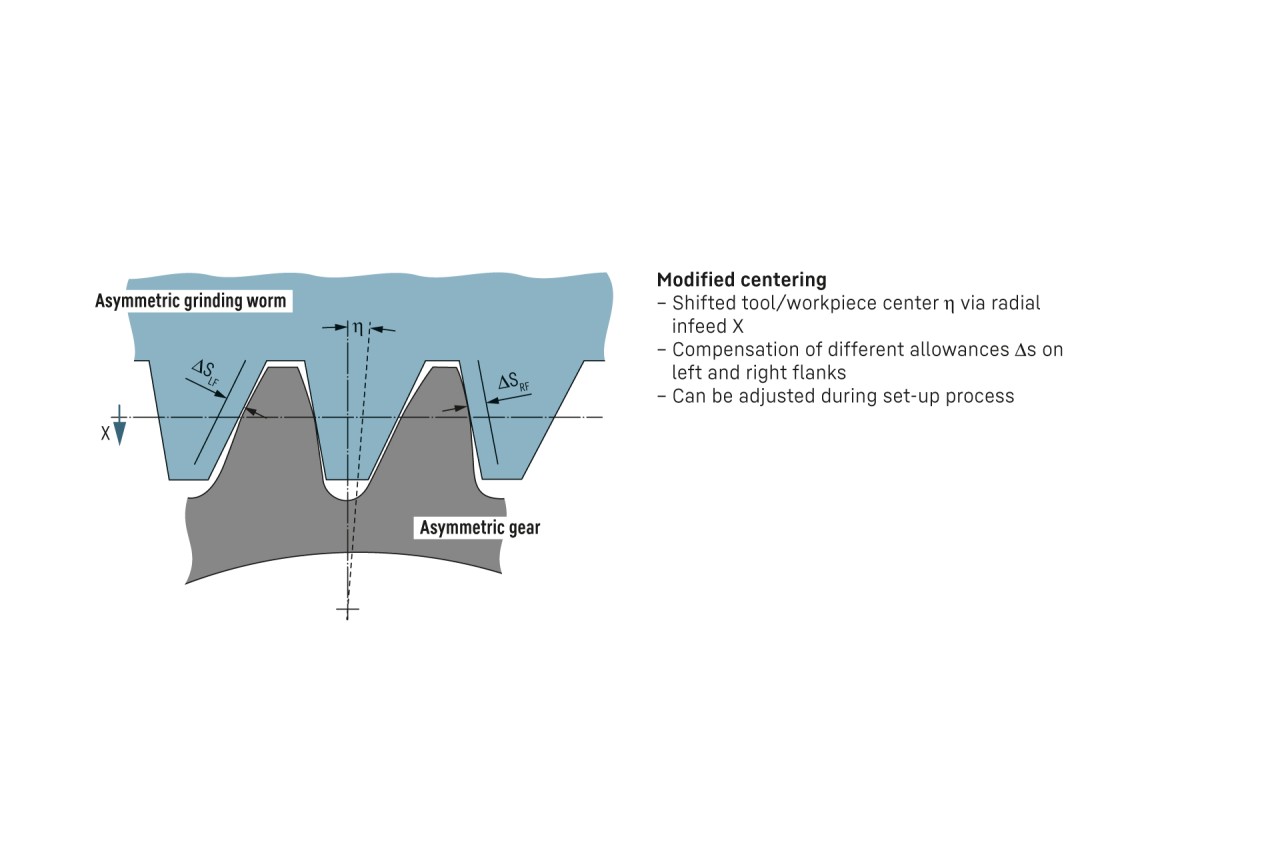

Generating grinding with small tools

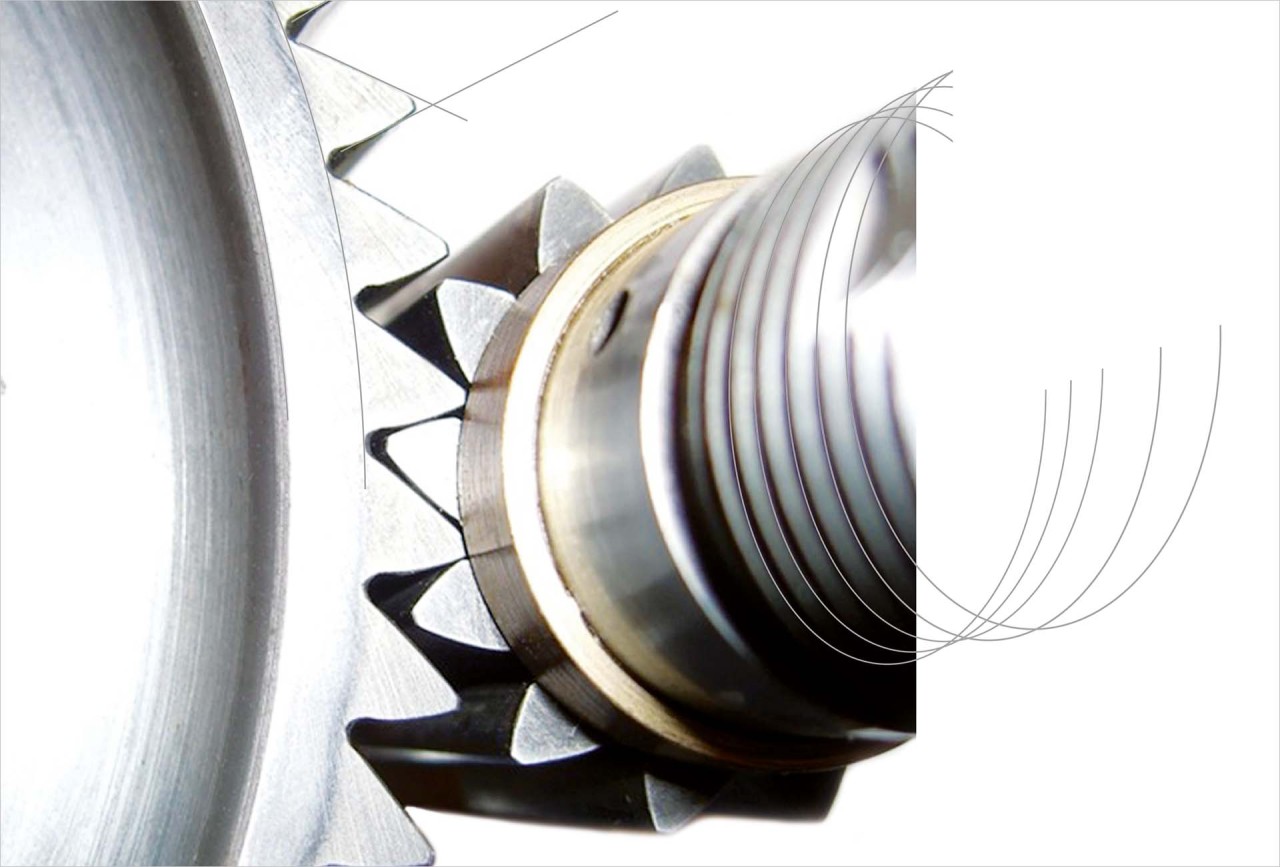

Finishing grinding or polishing

Generating or profile grinding with dressing-free CBN

Integrated centrifugal device

Automation

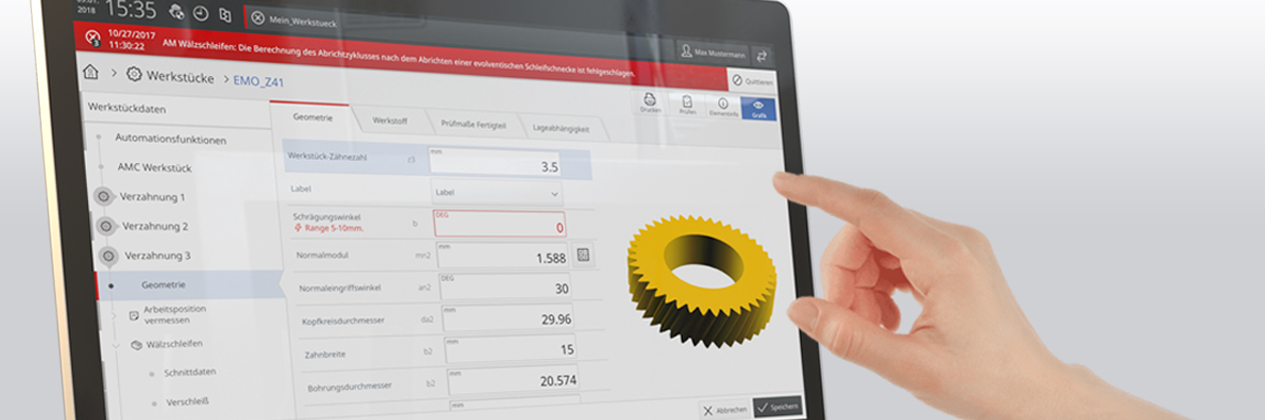

Easy to operate

Technical data

| Machine length | 3,500 mm |

| Machine width | 2,700 mm |

| Machine height | 4,000 mm |

| Axial travel | 1,000 mm |

| Min. position above table | 60 mm |

| Grinding head swivel angle | 45 ° |

| Workpiece speed | 1,000 min-1 |

Variants

| Variants | LGG 300 | LGG 380 | LGG 500 | LGG 700 M |

|---|---|---|---|---|

| Workpiece diameter (mm) | 300 | 380 | 500 | 700 |