Automation solutions for mechanical engineering

Mechanical engineering

Markets have become more fast-paced. That's why we have to adapt to changing market situations at increasingly shorter notice in the interests of our customers.

Variety needs flexibility

Mechanical engineering is in our blood. From construction machinery to machine tools, Liebherr itself has been producing with a high level of vertical integration for more than 70 years. That's why we understand firsthand the challenges in mechanical engineering.

When it comes to automation, the number one requirement is flexibility. The large variety of parts makes intelligent automation concepts necessary: from series parts such as hydraulic cylinders to the variant-rich production of similar parts such as valve blocks to the small batch manufacturing of massive workpieces such as machine beds or components in steel construction.

To ensure that our automation fits this wide range of parts, we offer a broad product portfolio from a quantity of 1 to series production. If requirements ever change, we will subsequently adapt the capacity of your manufacturing system to the changed demand. Our goal is to advise you individually and deliver a solution that works exactly for you and your manufacturing processes. Top quality, maximum flexibility and costs under control our automation supports you in this.

The requirements of the mechanical engineering industry

High mix/low volume

Flexibility

Individual consulting needs

The answer: automation

Automation from a batch size of one

Automation that grows with you

Intensive consulting

Mechanical engineering: how to automate your manufacturing processes

Flexible robot cells

LHRobotics.Vision

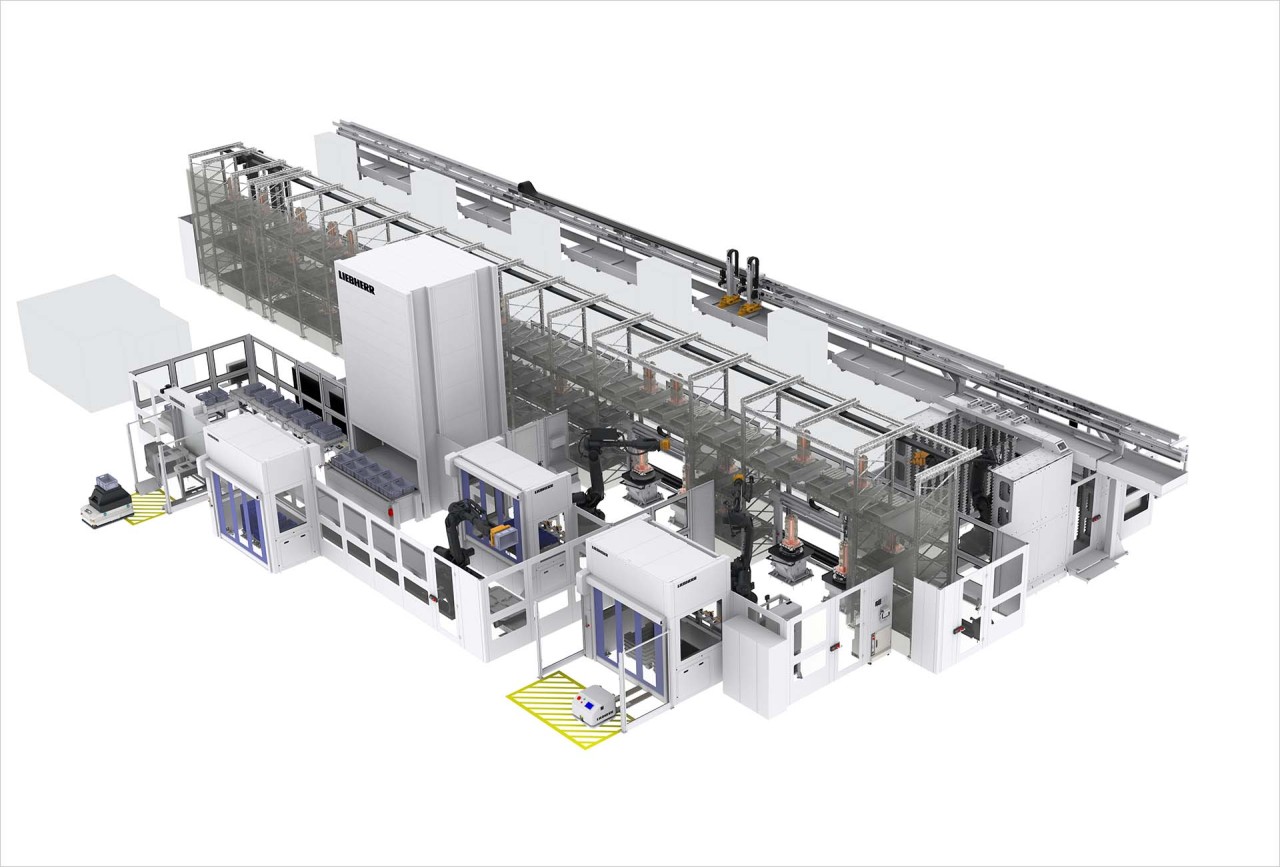

PHS pallet handling systems

Video

Pallet handling systems: manufacturing from batch size 1

On our visits to Kempten, we were advised and taught about all the details and felt very well informed. Here it became apparent to us that Liebherr, as a long-established family business, is a reliable partner representing dependable and high-quality German mechanical engineering.

Customer projects

Flexible, error-free and low-maintenance - that's Liebherr.