Technologies for the future

We believe in innovation – with continued investments into research and development Liebherr-Transportation Systems design solutions and components for the future of the railway industry.

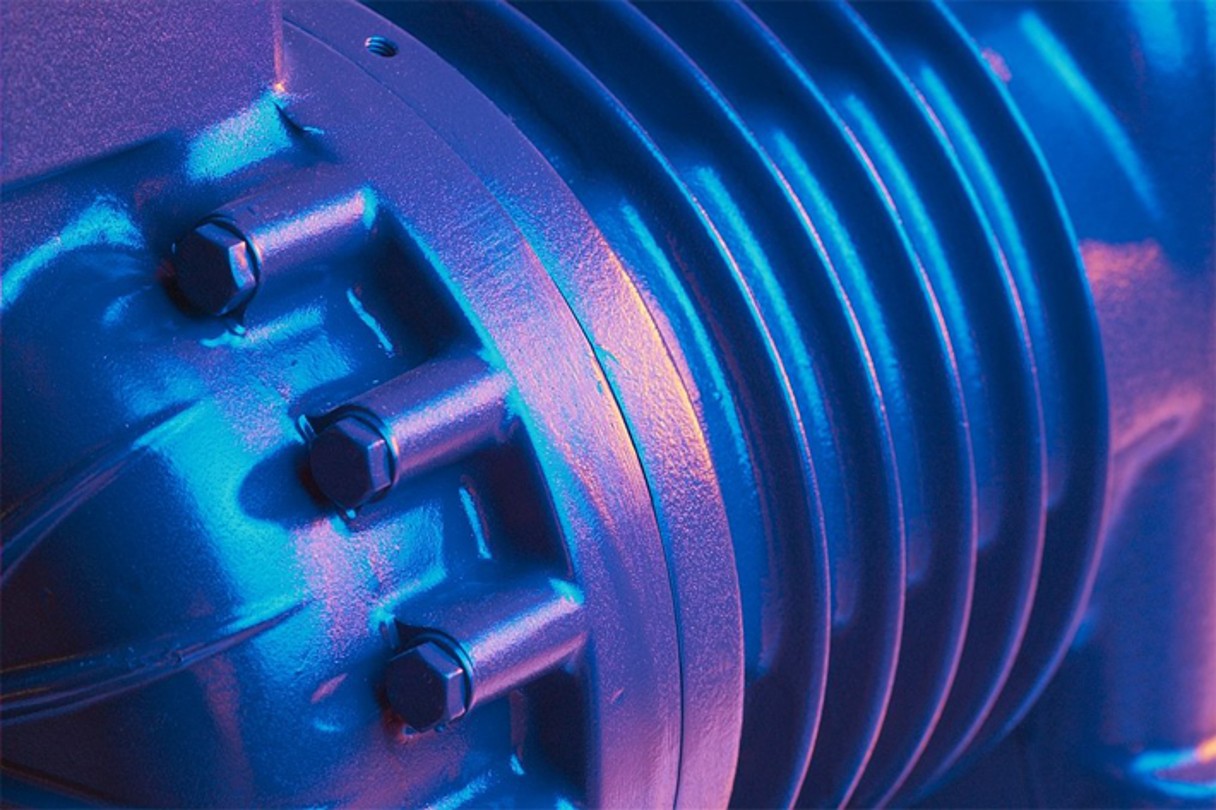

Liebherr’s air cycle air conditioning unit for the ICE 3.1: Liebherr’s cold air systems only consist of a few components. They are not only of low weight, but also simple and inexpensive to service. In addition, the systems are characterized by very low operating costs and low energy consumption.

Originally, air cycle air conditioning technology was developed for the aerospace industry, where it has been used for more than four decades for air conditioning in aircraft. As one of the very first companies, Liebherr also began employing this technology in rail vehicle equipment. In 2002, Liebherr-Transportation Systems fitted a train of German operator Deutsche Bahn AG (DB) – an ICE 3 – with air cycle air conditioning systems for test runs. Additional fittings for the first model series as well as 13 eight-car trains of the second model series of the ICE 3 followed.

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Data protection settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).Green technology for railway vehicles

Light-rail vehicle with charging system PRIMOVE® by Bombardier - Photo Bombardier

Li-Ion Battery Cooling System

Liebherr-Transportation Systems have been selected by the rail vehicle manufacturer Bombardier Transportation GmbH of Mannheim (Germany) to develop and produce a compact and reliable cooling system for an innovative Li-Ion battery.

Bus with system PRIMOVE®

These batteries will be employed in the next generation of electric drive systems, which are set to power urban transit buses and light-rail vehicles in the future. The highly efficient cooling system will ensure that the battery runs under optimal thermal conditions. Prototypes of the system are being tested both at Liebherr's ultramodern test facilities and on demonstrator vehicles at Bombardier.

Liebherr battery cooling unit for road application

The Li-Ion battery is an integral component in Bombardier’s highly innovative inductive battery charging system PRIMOVE®. This system enables the main battery of the electric drive system to be recharged without contact to the trolley wires, so the vehicle does not have to interrupt its operation. The battery charging system will play a major role in reducing CO2 emissions in urban traffic.

Liebherr technology cools the ITT Cannon HPC charging cable and connector during the charging process. - © ITT Cannon

Thermal Conditioning Units

Liebherr-Transportation Systems has been selected by ITT Cannon to supply active cooling units for its liquid cooled DC High Power Charging (HPC) solution. This contract enables Liebherr to contribute significantly to the further development of electro-mobility. Initial units of the cooling units, cables and connectors have already been delivered for assembly in EV ultra-fast charging stations in the USA and Europe.

The prototypes of the active cooling units - also known as Thermal Conditioning Units (TCU) - have been developed by Liebherr-Transportation Systems GmbH & Co KG, Korneuburg (Austria) specifically for e-mobility charging stations and were extensively and successfully tested beforehand by ITT Cannon, together with Efacec’s Electric Mobility division, one of the world leaders in fast and superfast charging. Liebherr's technology cools the innovative high-performance ITT Cannon HPC charging cable and connector to reliably limit a rise in temperature during the charging process.

The TCUs, in combination with the liquid-cooled cable and CCS connector, enable charging of electric vehicles. Installation in the first high-power charging station network, with an output power of 350 kW, a maximum current of 350 A and a high voltage of 1,000 V, have taken place in both the USA and Europe. In addition, the Liebherr team is developing additional cooling units to meet the increasing market requirements.

The Universal HVAC Standard for Multiple Railway Platforms

Liebherr-Transportation Systems has developed a modular air conditioning system which responds to the most challenging market requirements of the railway industry.

MACS 8.0 provides the highest degree of standardization. The modular architecture of MACS 8.0 allows flexibility and adaptability to serve diverse rolling stock applications.

MACS 8.0 - The chameleon among HVAC systems

Advantages

- Multi-platform standard

- Standardized design

- Flexible configuration

- Flexible service concepts

- Availability secured by modularity

- Cost efficient operation

- Constantly evolving product

- Future-proofed HVAC standard anticipates new cooling technologies

Technical features

- Flat profile: just 220 mm high

- Weighs only 125 kg per module

- 70 % greater cooling power density

- 8 % less power consumption

A significant reduction of greenhouse gas emissions is a major precondition for a sustainable traffic system covering all means of transport. Rail transport is generally considered as being green due to a high level of electrification, although not all railway tracks are electrified.

Railway operators and train manufacturers are working on green propulsion technologies to be introduced into locomotives and rail cars. One promising solution is the use of hydrogen in a fuel cell propulsion system.

Liebherr is part of this historical transformation process by offering its outstanding and highly reliable motorized compressor technology to fuel cell system integrators, based on its huge experience in fuel cell technology for automotive applications and in the aerospace sector.

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Data protection settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).