Flight control and actuation systems

Liebherr develops, supplies and supports flight control and actuation systems and takes care of the product management over the complete life cycle.

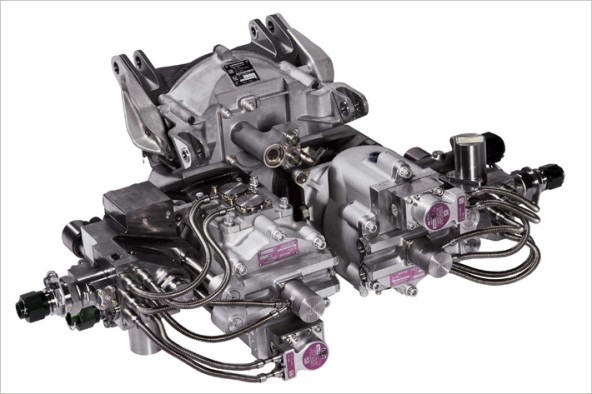

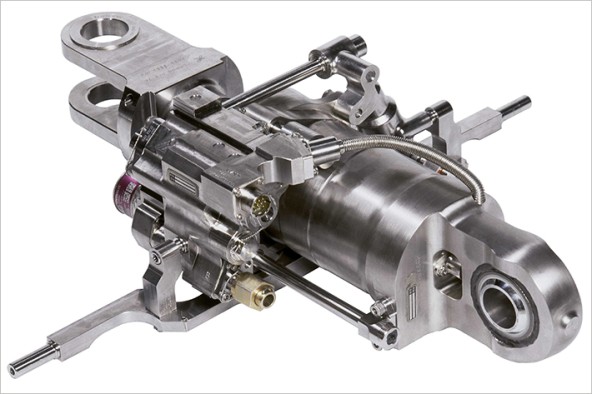

The A380 power control unit is an integral part of the high lift system that Liebherr-Aerospace supplies for this large aircraft

Liebherr offers primary and secondary flight control systems, other actuation systems and hydraulic systems. The core parts of these systems - i.e. mechanical, hydraulic parts and electronics hardware with embedded software - are developed and manufactured in-house.

As a system supplier, Liebherr is capable to design and qualify complete flight control and actuation systems, from side stick in the cockpit to the movable surface actuators on the wings. The scope covers primary and secondary flight control systems that can be hydraulically or electrically driven. Latest fly-by-wire systems are part of the product program in this area.

Flap ballscrew actuator for a fly-by-wire flight control system

High lift control systems are required to limit take-off and landing speeds by increasing wing high lift. This is achieved by wing leading and trailing edges extension devices.

High lift control systems can be driven hydraulically, electrically or with hybrid technology. For electrically driven systems that require high power electronic drives, Liebherr develops and produces special motor control units.

Flap and slat actuation

Liebherr develops and produces flap and slat actuation systems to extend the movable trailing edges and leading edge surfaces. These systems consist of a set of components that are installed along the wing trailing edge such as power control unit, geared rotary actuators, ball screw actuators, transmission shafts or position sensors. Liebherr’s capability does not only include the development and production of these components but also the system controller including hardware and software.

Liebherr-Aerospace supplies the four-axis actuator for the military helicopter Tiger.

The primary flight control system is part of the complete function needed to pilot an aircraft. It is actuating three sets of movable surfaces of the airframe - aileron, rudder and elevator. Liebherr supplies such control systems including actuators and electronic controllers.

Fly-by-wire

Fly-by-wire technology is part of the systems that Liebherr offers for new applications. Actuators can be hydraulically or electrically driven depending on the aircraft architecture. Latest technology electro hydraulic actuators (EHA), electric back-up hydraulic actuators (EBHA), or electro-mechanical actuators (EMA) have been successfully integrated into the Liebherr product portfolio.

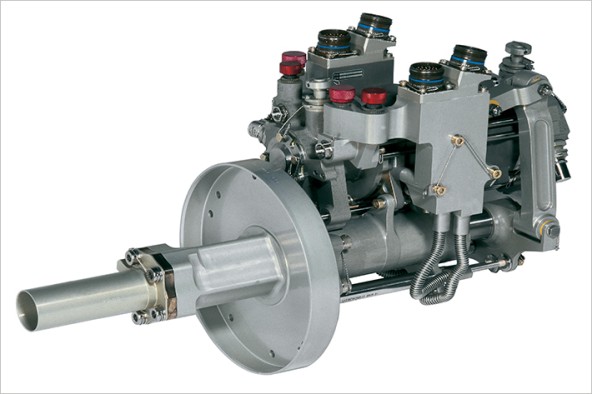

Tail rotor actuator, part of the fly-by-wire flight control system developed for the NH90 helicopter.

Main rotor and tail rotor actuation

Helicopters are controlled in their flight by acting on the rotor blades whether from the main rotor or from their tail rotor. This is achieved with dedicated actuators mostly hydraulically driven.

Liebherr develops and produces actuators for main and tail rotor as well as complete systems including actuators and actuator controllers.

Having developed one of the first fly-by-wire flight control systems for helicopters, Liebherr also has extensive experience in this area.

The A380 fly-by-wire electrohydraulic servoactuator by Liebherr-Aerospace is powered from a centralized hydraulic system. It is used to actuate spoiler surface position 4 of the Airbus A380 aircraft.

During certain aircraft flight phases, particularly during landing, it is necessary to quickly and strongly reduce the wing lift. This is achieved by rising dedicated wing control surfaces against the air flow going along the wing profile.

This is achieved with dedicated spoiler actuators that are currently most of the time hydraulically powered.

The rear horizontal stabilizer of an aircraft is used to stabilize the airframe during the flight. To adjust this stabilizer at an appropriate position, an actuator is used that drives it to required setting. On most recent aircraft, this actuator, mostly of ball screw type, is hydraulically or electrically driven.

Boeing 777X

Liebherr supplies a wide variety of utility actuation systems for multiple applications. Our product portfolio ranges from door actuators, latch and locking systems up to complex actuation systems for wing tip folding or air refueling.

We develop and manufacture actuators to open and close doors for applications like cargo doors, weapon bay doors or landing gear doors. Liebherr also is able to supply complete customized door actuation systems featuring actuators, control manifolds and system electronic controllers with embedded software.

Latch and Locking systems include landing gear up-locks and ramp door latch actuators for military transport aircraft.

The world’s first commercial aircraft featuring folding wingtips, the Boeing B777X, is equipped with a hydraulically driven folding mechanism made by Liebherr, including a power drive unit, geared rotary actuators and latch/locking actuators.

The most advanced air refueling systems, used on A330 MRTT, A400M, KC-46 or KC-390 are equipped with Liebherr Hose Drum Drive Systems. The Liebherr Ruddervator Control Systems supports the operation of the A330 MRTT boom refueling system.

Commercial aircraft engines are equipped with a thrust reverser helping to decelerate the aircraft after touch down by reversing the direction of the exhaust stream. This helps to reduce the stress on the landing gear brakes and constitutes a major safety feature for landing in bad weather conditions, when the aircraft brakes might no longer be effective enough to bring the aircraft to a stop.

Liebherr-Aerospace provides the Thrust Reverser Actuation System (TRAS) to move the thrust reverser doors when activated by the pilot. A typical hydraulically actuated TRAS comprises door actuators, locking/unlocking actuators, hydraulic valve blocks, check valves, position sensors and hydraulic control units.

Thrust Reverser Actuation Systems are considered as being safety critical. The system needs to be designed in a way that a deployment of the system during flight is impossible.

Liebherr-Aerospace is also capable to develop Electrical Thrust Reverser Actuation Systems, using electro-mechanical actuators instead of hydraulic actuators.

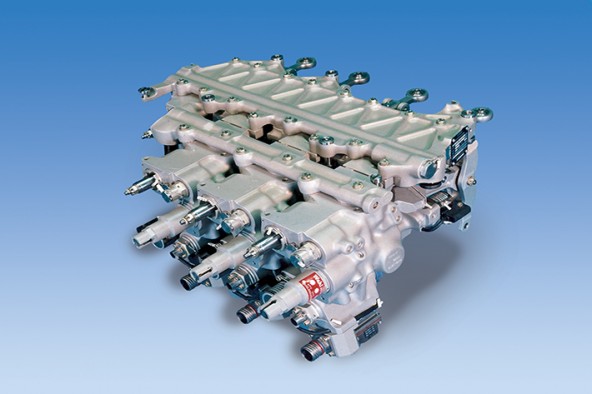

Filter package by Liebherr-Aerospace for the Eurofighter program. Each filter package filters the high pressure flow to the consumers on board the aircraft and the low pressure flow to the pump at flow rates up to 240 l/min.

Liebherr develops and manufactures hydraulic pumps and motors ranging from 1,500 psi over 3,000 psi up to 5,000 psi. These piston pumps and motors are used in high reliability applications like electro-hydraulic actuators or high lift systems on commercial airplanes and military transport aircraft.

Electrically driven pumps are also part of the Liebherr product portfolio. They are used on board different aircraft like fighters and helicopters.

System control

Aircraft and helicopters use hydraulic circuits to power different systems like flight control actuation, landing gear extension and retraction or landing gear door actuation. These utility functions require system control in order to fulfil the various tasks in the right sequence, for example to open doors, deploy mechanism and lock the doors in the open position.

This is achieved with customized manifolds featuring complex hydraulic circuits and carrying various components like sensors or valves. Selected materials are aluminum, steel and titanium.

Liebherr is a specialist in designing, developing and manufacturing of such system control components.

Liebherr-Aerospace's test rig for the A380 gear rotary actuator

Liebherr has complete flight control actuation system testing capabilities.

In a dedicated test center in Lindenberg, Germany, the various subsystems can be installed and tested together. Liebherr designs and manufactures the test rigs for complete primary and secondary flight control systems integration including the test rig control load and failure simulation.

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Data protection settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).