Automation solutions for the automotive industry

Automobile

An industry in a state of transformation

The automotive industry is undergoing a historically unique transformation. Regulatory changes, disruptive technologies and new competitors from outside the industry are radically changing the rules of the game in what was once a clearly structured market. However, every change also offers opportunities for those who adapt to the altered market environment in good time.

The transformation to electrified powertrains requires significant investment in new technologies and production facilities. Automation plays a key role here, allowing vehicle components to be produced economically in large volumes.

The demands of the automotive industry

High volumes

Quality

Efficiency & flexibility

The answer: automation

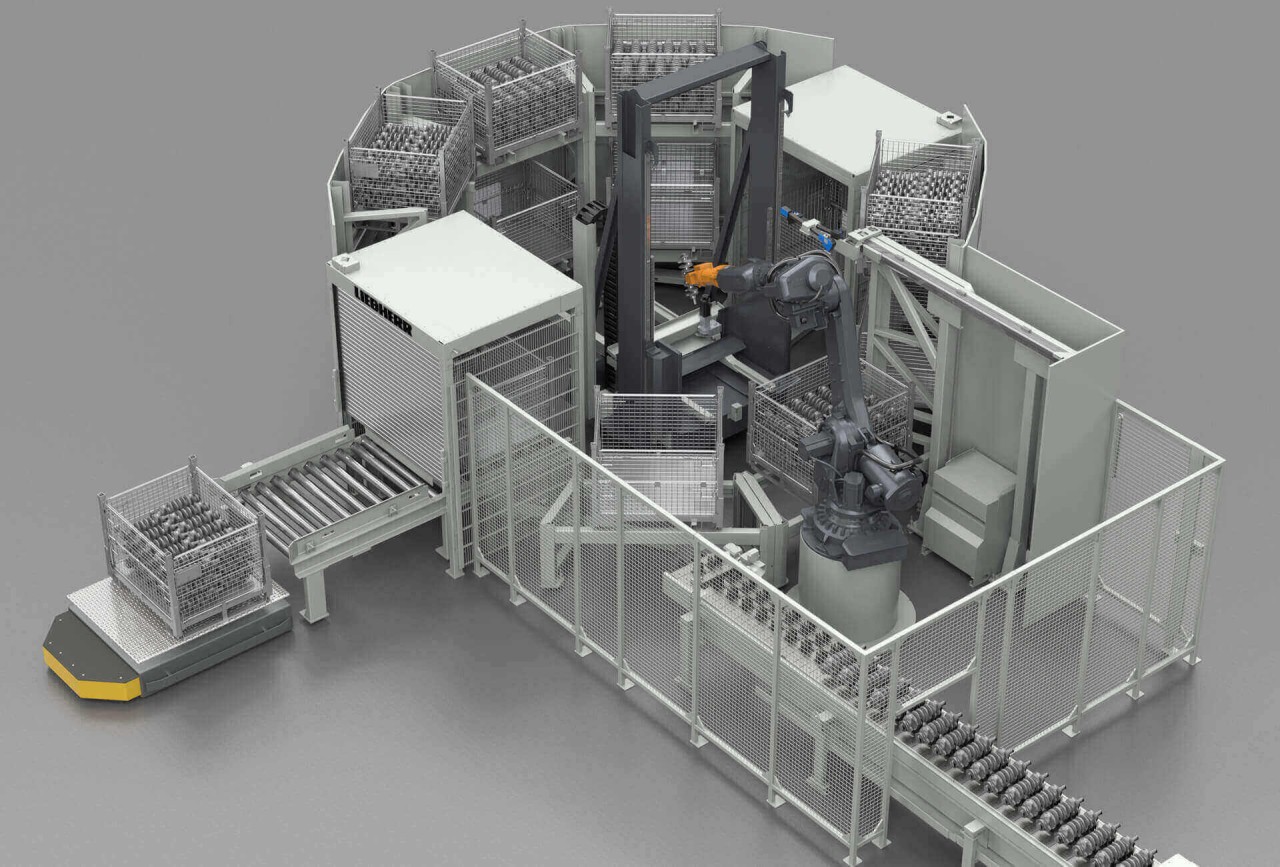

Turnkey system solutions

Traceability

Retooling

Automotive industry: how to automate your manufacturing

Conventional powertrain

Circular economy: battery pack disassembly

Video

Liebherr Manufacturing System LMS 4.0

Software solution for monitoring and supporting manufacturing processes. The software is available in individually configurable packages.

- Production Schedule App

Management of production orders and processes - Part Tracking App

Guarantee of reliable process within a manufacturing or assembly line, as well as long-term logged part tracking - Production Monitoring App

Recording of production and operating data - Info Board App

Display of the plant status on a large display screen or simply on mobile devices