Click RELEASE VIDEO and follow the data protection notices.

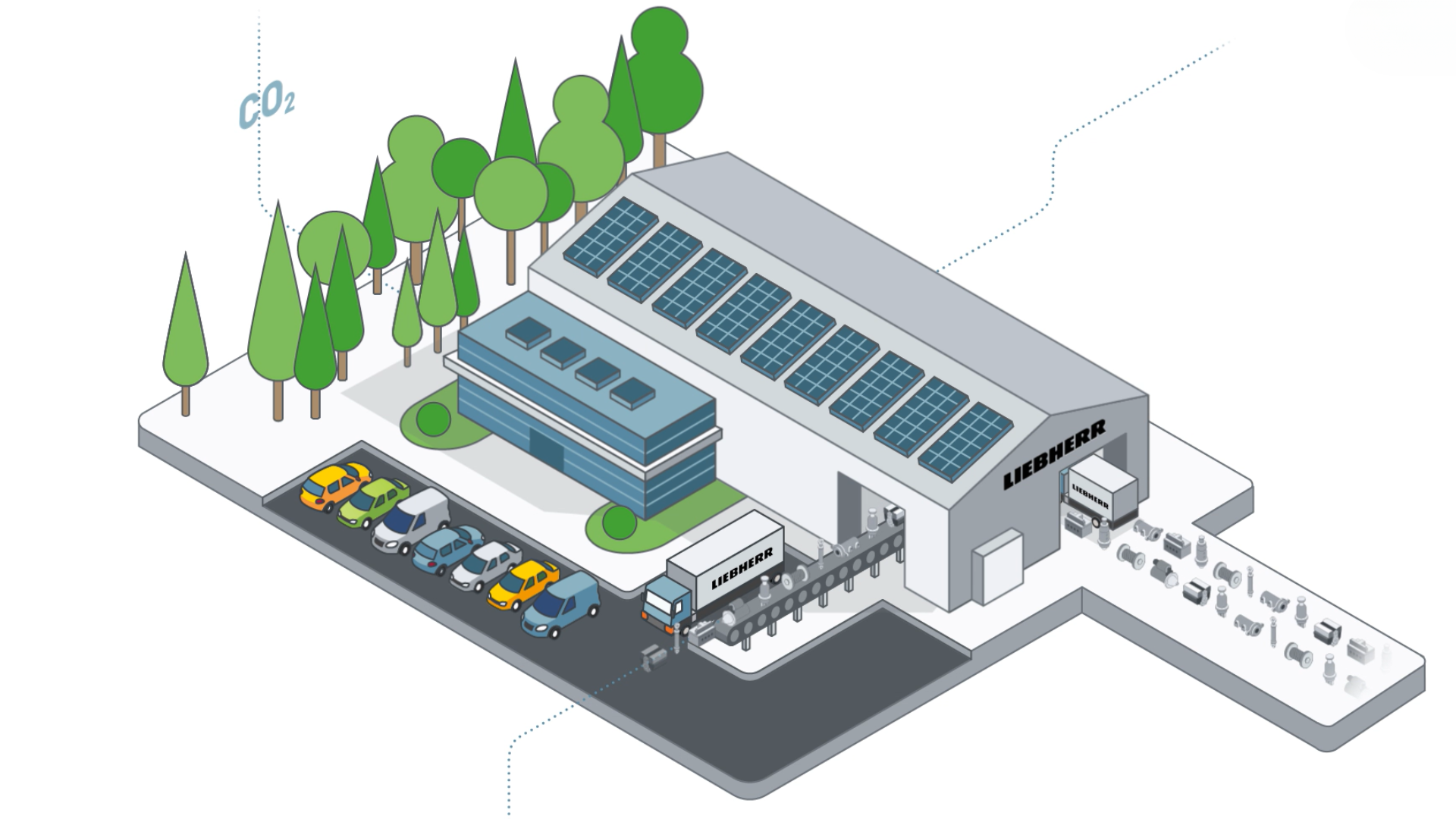

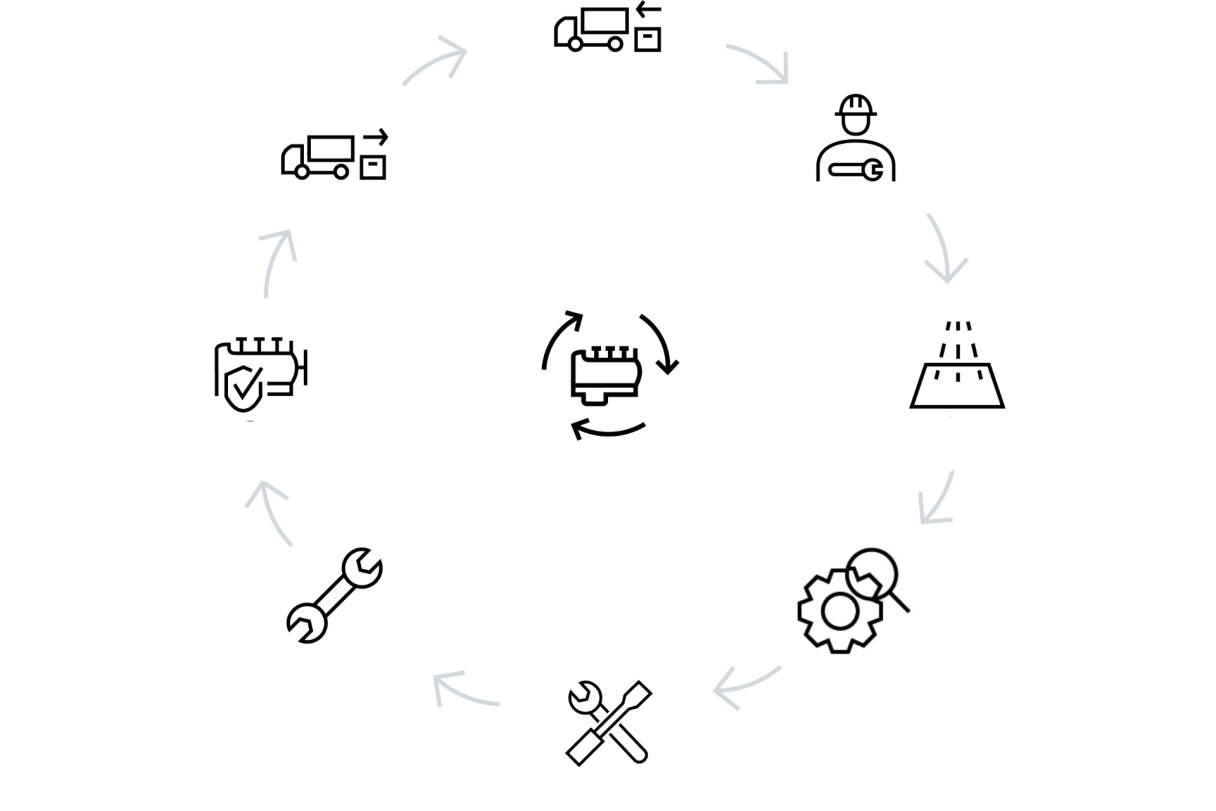

Discover the Liebherr Reman production line and find the different steps of remanufacturing process, dedicated to reclaiming used parts, also known as cores. The process commences with the thorough disassembly of the core. Wear parts are responsibly disposed of, and potentially reusable elements undergo a meticulous process of paint removal, cleaning, and appraisal, adhering to strict guidelines.

Through the assistance of automated tolerance measurements and crack inspections, the suitability for reconditioning of each part is precisely determined. Advanced industrial machining processes then meticulously restore these parts to a quality equivalent to new before undergoing rigorous inspection and reuse. Finally, the complete remanufactured component undergoes testing, aligning with the same stringent criteria and inspection report applied to its brand-new counterpart.

Explore the steps involved in the Reman process at Liebherr

Hover over the yellow dots for more information.

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).