Success through user-friendly solutions

The intelligent assistance systems for the Liebherr wheel loaders support the operator in their daily work. These include active personnel detection at the rear, a new joystick steering system and an integral tyre pressure monitoring system. These and other assistance systems enable Liebherr to offer holistic solutions to optimise safety and comfort and increase performance.

All systems have been developed by Liebherr and are therefore fully integrated in the machine control. It is important for operators to be in a comfortable and safe operating area, where they can concentrate longer and work more efficiently. These useful assistance systems for Liebherr wheel loaders reduce the risk of accidents and their easy operation enables safe and efficient machine operation.

Adaptive working lighting is an intelligent lighting control system that adjusts the brightness of the headlights to suit the application.

Adaptive working lighting

The adaptive working lighting is an intelligent light control system optionally available for the Liebherr L 526 - L 586 XPower wheel loaders. The system adjusts the brightness of headlights according to the application. The various lighting components are only switched on when they are needed - a fully automated process.

With the help of modern light sensors, the light output of the LED headlights automatically adjusts to the position of the lift arms, the working attachment and the wheel loader’s articulation angle. This enables uniform illumination of the entire operating area. An additional headlight on the front section of the vehicle and automatic dimming of the front working headlights ensure that the operating area is ideally illuminated at all times to prevent the operator from dazzling themselves. This also reduces reflections and shadows. Ideal visibility conditions thus ensure a high level of safety and enable the operator to work comfortably and without fatigue, especially in the dark and at night.

Video

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).

The roof camera offers the operator an extended field of vision and excellent visibility of the front operating area of the wheel loader.

Roof camera for front area monitoring

The roof camera, which is optionally available for the Liebherr L 526 - L 586 XPower wheel loaders, offers the operator an extended field of vision and excellent visibility of the front operating area of the wheel loader. It is used, especially in applications with large working attachments (e.g. a light-weight or high dump bucket) for better and faster recognition of people and obstacles in the front area of the machine. The operator can immediately identify possible sources of danger on a separate display in the operator’s cab. This increases safety and protects against accidents involving personal injury. In addition, the improved visibility into high containers, trucks and hoppers enables more efficient loading and feeding and increases productivity.

The Skyview 360° camera simplifies the monitoring of the machine environment.

Skyview 360°

Everything in view – the Skyview 360° system has been fundamentally revised and now has impressive high-definition image quality. The system offers an overview of the whole area around the machine, so that potential hazards can be identified earlier and accidents prevented.

The optional Skyview 360° assistance system for the Liebherr L 526 - L 586 XPower wheel loaders simplifies monitoring of the machine environment. Skyview 360° offers the operator a 360-degree view around the wheel loader at all times, with four additional cameras covering the entire machine environment. The images from these cameras are combined to form a bird’s eye view of the machine environment which is shown on a separate display in the operator’s cab. A glance at the additional display therefore allows the operator to see any obstacles from a bird’s eye view, 360° around the wheel loader. This enables the operator to quickly see and classify all danger areas and blind spots, increasing safety and productivity.

The images from the Skyview 360° camera are shown on the display in the operator’s cab.

Skyview 360° assistance systems and the active personnel detection at the rear can be combined. They offer the operator safe and comfortable operation of the wheel loader and the best possible monitoring of the entire machine environment.

Video

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).

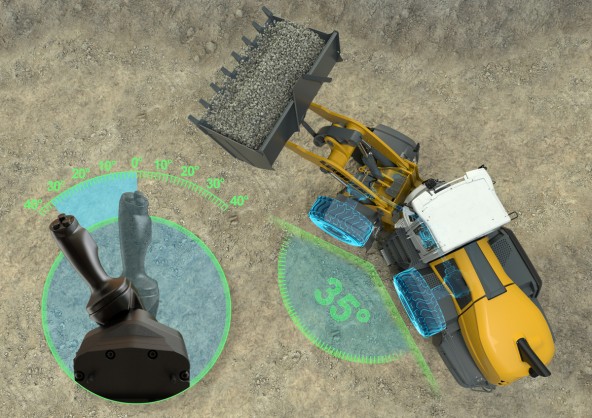

The optional joystick steering integrated in the operator’s seat is a new, innovative and improved steering system.

Joystick steering

The joystick steering integrated in the operator’s seat and optionally available for Liebherr L 526 - L 586 XPower wheel loaders is a new, innovative and improved steering system. This means that all working and driving functions of the machine can be controlled with precision and a high degree of sensitivity. The new joystick steering system enables easy and fast manoeuvring. In addition, the new steering system offers high steering and vehicle control for reverse travel.

The new joystick steering solution gives the operator precise information about the wheel loader’s steering direction. This is because the joystick’s orientation corresponds exactly to the current wheel loader articulation angle.

The new joystick steering solution gives the operator precise information about the wheel loader’s steering direction. This is because the joystick’s orientation corresponds exactly to the current wheel loader articulation angle.

In addition, the intelligent force feedback ensures both smooth and safe steering. This enables precise and safe operation at any speed and in all terrain conditions.

For the Liebherr L 526 – L 586 XPower wheel loaders, the operator’s cab is optionally available without a steering wheel and column, i.e. only with joystick steering. The elimination of the steering wheel and column provides more space and improved visibility of the working attachment and the operating area.

For the Liebherr L 526 – L 586 XPower wheel loaders, the operator’s cab is optionally available without a steering wheel and column, i.e. only with joystick steering. Above all, an operator’s cab without a steering wheel and column offers more space and an improved view of the working attachment and the operating area. In addition, it is not necessary to reach between the steering and control units, which increases safety and comfort. This offers the operator optimum conditions for comfortable and productive working.

Video

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).

The optionally available Liebherr key with remote control and Coming Home/Leaving Home function enables the machine to be put into service in a safe and convenient manner.

Liebherr key with remote control incl. Coming Home / Leaving Home function

The Liebherr key with remote control and Coming Home/Leaving Home function, which is optionally available for the Liebherr L 550 XPower – L 586 XPower wheel loaders, enables the machine to be put into service in a safe and convenient manner. This allows the operator’s door to be locked and unlocked remotely and opened automatically. In addition, the side-mounted working headlights illuminate the immediate vicinity of the machine and ensure safe and quick entry and exit. This minimizes the risk of accidents and significantly increases safety, especially in the dark and at night. This saves time and increases productivity.

The weighing data is clearly displayed on the Liebherr weighing system on the display in the operator’s cab enabling the operator to work comfortably and efficiently.

Weighing system Liebherr with "Truck Payload Assist"

The optionally available weighing system for Liebherr L 526 – L 586 XPower wheel loaders serves as a checking scale and functions automatically and intelligently with dynamic weighing range adjustment. The weighing extends over a large lifting range without the need for a special lifting height to be reached. In addition, the weighing data is clearly displayed in the operator’s cab to enable the operator to work comfortably and efficiently.

In addition, the operator can enter the desired load weight on the display. Truck Payload Assist then suggests the optimum target weight of the individual shovel fillings and the necessary loading cycles for an even loading process. This ensures precise, efficient and gentle loading of trucks, dumpers and containers. This allows operators to carry out their work in a concentrated and uninterrupted manner without the need for time-consuming re-weighing. As a result, time and money is saved, and the productivity of the operator and machine are significantly increased. For even more efficient machine operation, the weighing data can also be evaluated via LiDAT.

Video

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).

With the aid of sensors installed on the tyres and protected from damage, the system records the status of the tyres and indicates this on the display in the operator’s cab.

Integral tyre pressure monitoring system

Tyres are among the most expensive wearing parts on a wheel loader. Incorrect tyre pressure leads to increased wear and rising fuel consumption, resulting in high costs. Further negative effects are restrictions in handling characteristics such as stability, traction and operating comfort. It is therefore important to counteract deficient tyre pressure quickly and to detect possible tyre damage at an early stage. For this purpose, Liebherr offers a new, integral tyre pressure monitoring system, which is optionally available for the Liebherr L 526 – L 586 XPower wheel loaders.

With the aid of sensors attached to the tyre valves and protected against damage, the system detects any tyre pressure defects early on and displays them on the display in the operator’s cab. If there are deviations, the operator receives a warning notification on the display. The operator can therefore act at an early stage if there is insufficient pressure or excessive temperatures in order to avoid safety risks and their subsequent high costs. This considerably extends the lifetime of the tyres. In addition, optimum tyre pressure ensures good handling characteristics as well as high stability of the machine.

Active personnel detection at the rear

The active personnel detection system monitors the rear area of the wheel loader and automatically warns the operator of dangers by means of a visual symbol on the display and an acoustic signal. Another aid for avoiding collisions is the brake assistant. The brake assistant automatically slows the speed of the wheel loader to a standstill the moment the active personnel detection issues a warning signal. With the aid of the latest camera technology, the system distinguishes between people and objects without the people needing to be equipped with transponders or sensors. This makes the Liebherr system one of the safest currently on the market. In addition, pedestrians are warned by an acoustic signal and a clear flashing light when they are in the machine's hazard zone.

Intuitive incident map via LiDAT

The active personnel detection system monitors the rear area of the wheel loader and automatically warns the operator of dangers by means of a visual symbol on the display and an acoustic signal. Another aid for avoiding collisions is the brake assistant. With the aid of the latest camera technology, the system distinguishes between people and objects without the people needing to be equipped with transponders or sensors. This makes the Liebherr system one of the safest currently on the market.

Video

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).

Solidlink

Ready for new tasks at the push of a button.

The Solidlink quick coupler system allows the operator to safely and conveniently change mechanical and hydraulic working tools at the push of a button from the cab.

Quick and safe equipment changes when operating a wheel loader.

Solidlink is available for:

- Compact Loaders L 504, and L 508

- Stereoloaders and

- XPower large wheel loaders up to the L 580

- Medium-sized Liebherr wheel loaders

Automatic bucket functions

Automatically practical – the optional and individually available assistance systems allow faster work

cycles for more effective and therefore more productive work.

- Bucket tilt assistant

- Visualisation of the attachment position

- Stroke limit damping

- Programmable bucket return-to-dig function

- Programmable lifting and lowering automatically

Video

By clicking on “ACCEPT”, you consent to the data transmission to Google for this video pursuant to Art. 6 para. 1 point a GDPR. If you do not want to consent to each YouTube video individually in the future and want to be able to load them without this blocker, you can also select “Always accept YouTube videos” and thus also consent to the respectively associated data transmissions to Google for all other YouTube videos that you will access on our website in the future.

You can withdraw given consents at any time with effect for the future and thus prevent the further transmission of your data by deselecting the respective service under “Miscellaneous services (optional)” in the settings (later also accessible via the “Privacy Settings” in the footer of our website).

For further information, please refer to our Data Protection Declaration and the Google Privacy Policy.*Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland; parent company: Google LLC, 1600 Amphitheatre Parkway, Mountain View, CA 94043, USA** Note: The data transfer to the USA associated with the data transmission to Google takes place on the basis of the European Commission’s adequacy decision of 10 July 2023 (EU-U.S. Data Privacy Framework).